Direct Logic PLC is a series of programmable logic controllers designed for small to medium-sized automation tasks. These controllers are easy to program and maintain, making them ideal for both experienced professionals and those new to automation.

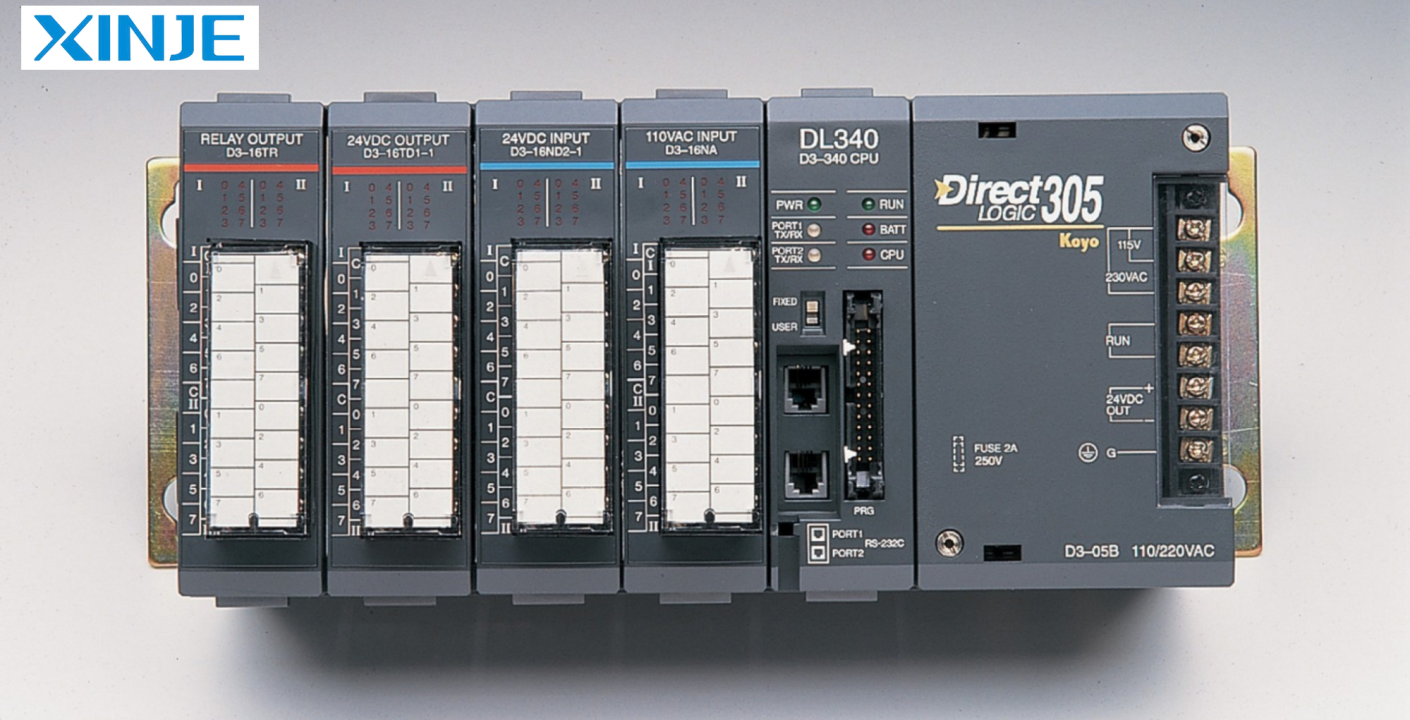

The Direct Logic series offers a range of models such as the DL05, DL06, DL205, and DL405, each catering to different needs based on input/output (I/O) requirements and processing power. These devices are engineered to integrate seamlessly into existing systems, offering modular designs and expandable capabilities to meet diverse industrial demands.

What are the features of Direct Logic?

Direct Logic PLCs are known for their reliable performance and innovative design, making them an ideal choice for industrial automation across a wide range of applications. Combining user-friendly software, scalability, and cost-effectiveness, these PLCs are specifically designed to meet the evolving needs of modern industries. Key features that make Direct Logic stand out from the crowd include

- Compact Design: Direct Logic PLCs are designed with space-saving modularity, ensuring they fit into tight control panels.

- High Performance: Equipped with fast processing speeds, these PLCs handle complex tasks efficiently.

- Wide I/O Support: Direct Logic PLCs support a wide range of digital and analog inputs and outputs, allowing integration with a wide range of sensors and actuators.

- User-friendly software: The programming software, DirectSOFT, is intuitive, with features such as drag-and-drop programming and debugging tools.

- Networking options: Direct Logic PLCs support multiple communication protocols such as Ethernet, Modbus, and RS-232, ensuring compatibility with modern industrial systems.

- Scalability: The modular design allows users to expand their systems as their operational needs grow.

- Cost-effective: AutomationDirect’s focus on affordability makes Direct Logic PLCs accessible to businesses of all sizes.

In which fields is Direct Logic PLC used?

Direct Logic PLCs are the foundation of automation, providing powerful and flexible solutions for a wide range of industries. Their ability to streamline processes, improve efficiency, and ensure accuracy makes them invaluable in areas such as manufacturing, agriculture, and water treatment. Some typical applications of Direct Logic include:

- Manufacturing: Automating assembly lines, monitoring equipment, and ensuring consistent product quality.

- Oil and Gas: Controlling drilling operations, managing pipelines, and monitoring pressure and flow rates.

- Agriculture: Automating irrigation systems, managing livestock feeding schedules, and monitoring environmental conditions.

- Food and Beverage: Maintaining hygiene standards, controlling packaging systems, and ensuring precise mixing of ingredients.

- Building Automation: Managing HVAC systems, lighting controls, and access systems for enhanced energy efficiency and security.

- Water Treatment: Controlling filtration processes, monitoring water quality, and automating distribution systems.

How to download the Direct Logic PLC program?

To start using Direct Logic PLC, you need to download the DirectSOFT programming software. You can refer to the download process which will go through the following steps

- Visit the Official Website: Navigate to the AutomationDirect website to find the latest version of DirectSOFT.

- Create an account: Register for an account if necessary. This allows access to downloads and technical support.

- Locate the Software: Use the search function or browse the “Software” section to find the DirectSOFT programming software.

- Select Version: Select the version that matches your PLC model and operating system.

- Download: Click the download link and save the installation file to your computer.

- Install the Software: Follow the on-screen instructions to install DirectSOFT on your system. Make sure your system meets the minimum requirements for optimal performance.

What should I keep in mind when downloading Direct Logic PLC?

When downloading DirectSOFT for your Direct Logic PLC, there are a few key considerations that can ensure a seamless experience and optimal performance, such as:

- Check System Compatibility: Make sure your computer meets the software’s hardware and operating system requirements.

- Verify Source Only download: DirectSOFT from AutomationDirect’s official website or authorized distributors to avoid malware risks.

- Stable Internet Connection: A reliable Internet connection ensures smooth downloads without interruptions.

- Update Firmware: Before programming, check if your Direct Logic PLC requires a firmware update to ensure compatibility with the latest software.

- Backup Data: If updating or reinstalling, back up your existing projects to avoid data loss

Conclusion

Direct Logic PLC is an essential automation tool that offers powerful features and versatility for various industries. Its ease of use, cost-effectiveness, and adaptability make it a favorite among engineers. You can unlock its full potential by understanding its features and applications and following the steps to download and install the software.

Whether you are new to automation or a seasoned pro, Direct Logic PLC offers the reliability and scalability needed to optimize processes and improve productivity.