Stable and Reliable, Neat Cable Arrangement, Easy to Operate

Depending on the control method and mechanical structure, wire drawing equipment can be classified into various types, such as tank-style, pulley-style, and straight-through-style. Metal wire drawing machines are widely used in industries such as steel wire, rope making, wire and cable manufacturing, cutting wire, and welding wire

Industry Background

Wire drawing is a process where materials of larger diameters are pulled through multiple stages to achieve the desired specifications. A wire drawing machine generally consists of a decoiler, multiple drawing dies, a wire alignment device, and a wire take-up device. The wire drawing machine refers to the equipment that transforms materials into fine wires of the desired specifications using multiple drawing dies and winds the wires onto a fixed spool.

Depending on the control method and mechanical structure, wire drawing equipment can be classified into various types, such as tank-style, pulley-style, and straight-through-style. Wire drawing machines can also be categorized based on their purpose, such as metal wire drawing machines, fiber drawing machines, and bamboo/wood drawing machines. Metal wire drawing machines are widely used in industries such as steel wire, rope making, wire and cable manufacturing, cutting wire, and welding wire.

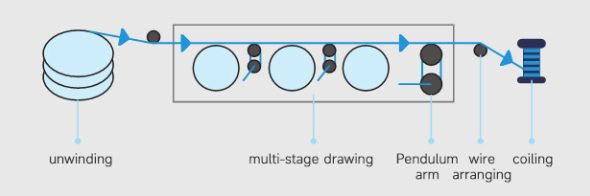

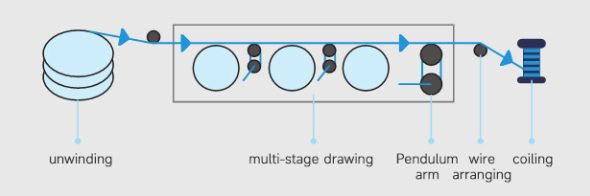

System principle

The straight-line wire drawing machine, through progressive drawing, can cold draw the steel wire to the desired specifications at once. It is a high-speed, efficient, non-bending, non-twisting, strong cooling, and cost-effective continuous wire drawing machine. The equipment is mainly divided into several parts: unwinding, multi-stage drawing, wire arranging, and coiling.

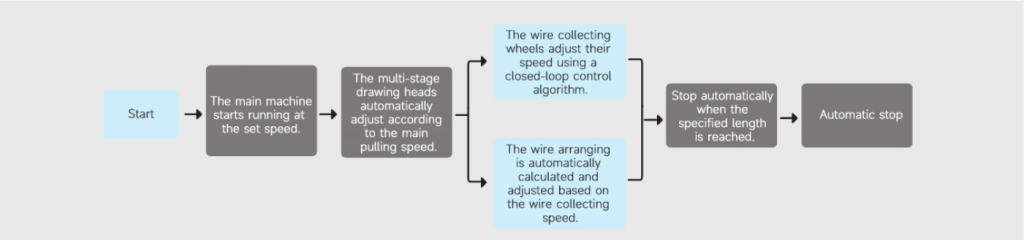

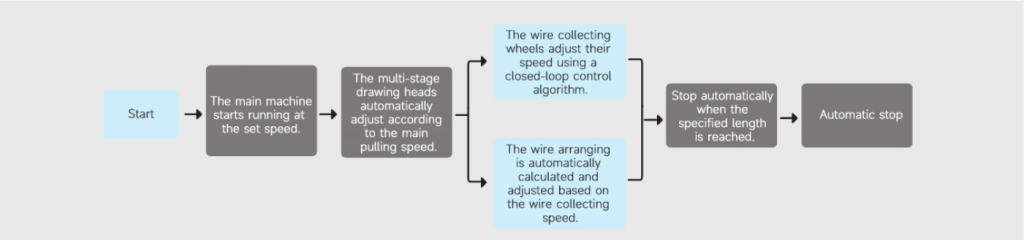

Process flow

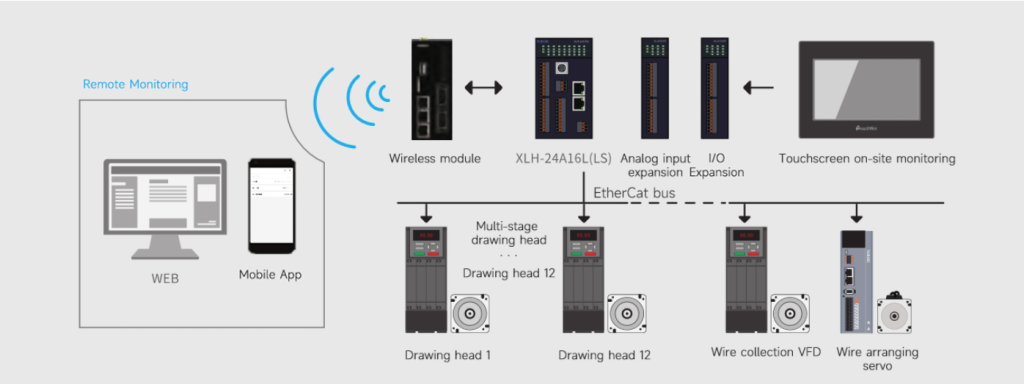

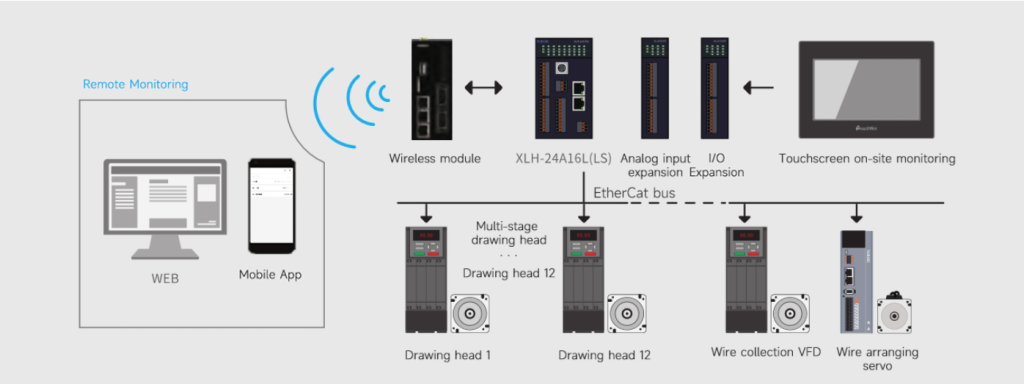

System topology