Efficient, flexible, reliable and stable

With the popularization of the application of informatized big data, the traditional warehousing and logistics operation methods have been unable to meet the rapidly growing business needs, and it is necessary to accelerate the construction of automation and intelligence of warehousing and logistics. The introduction of intelligent warehousing can efficiently connect production and logistics and improve the production efficiency of enterprises.

System Introduction

Magnetic stripe navigation steering wheel AGV is mainly applied to the cargo handling of loads over 1 ton. The adoption of the steering wheel structure can realize multi-directional movement more flexibly. Through the cooperation of jacking up and together with the platform, the handling efficiency is improved, and the labor cost and time cost are reduced, and the factory production automation is enhanced.

Application scenarios

Load capacity: Suitable for handling goods with a load of 1 ton or more.

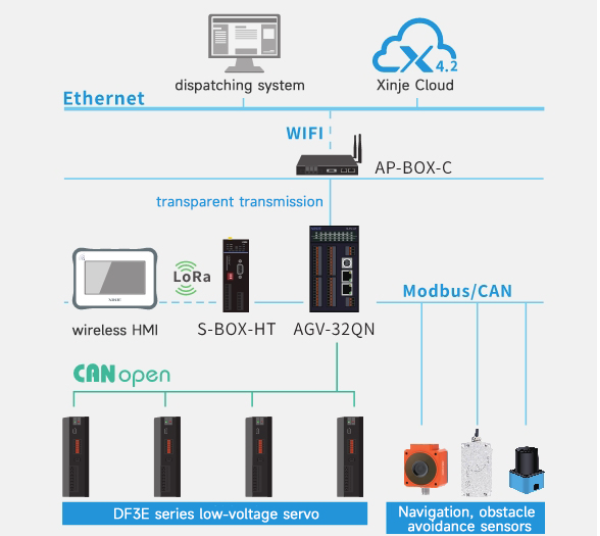

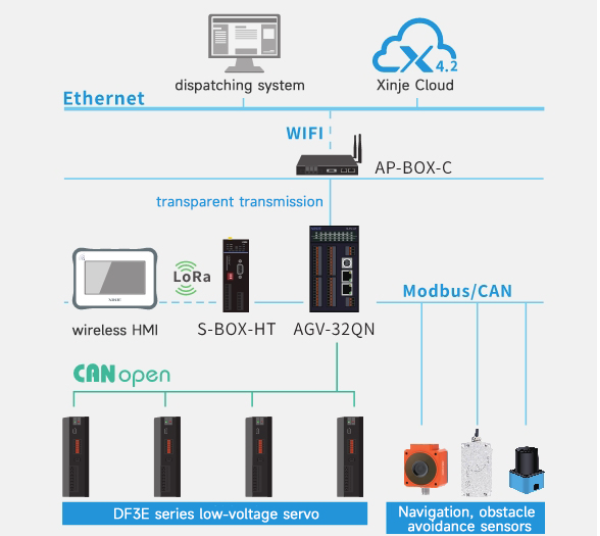

Control solution

The control system adopts the method of steering gear (driving + rotation) for driving control. The steering angle of the rotating shaft of the steering gear is controlled through the data detected by the magnetic guide sensor, and combined with the calculated speed of the driving shaft, the correction and steering in the movement process are realized to ensure that the AGV can stably walk along the set task path.

When the RFID sensor detects the function tag card arranged on the AGV walking path, the AGV begins to perform functions such as fork selection, in-place rotation, and stop, etc., to realize the navigation control, function control and safety protection of the AGV.