Description

Cutting-edge expertise, versatile excellence, driving high-precision industries to new frontiers

3.8kHz high-speed response, 250μs synchronization cycle, powered by advanced control algorithms. Proprietary resonance suppression algorithm. Dynamic braking and STO for enhanced safety. Gantry synchronization, long-line drive, frequency division output, and Type-C, everything you need, all in one!

Lightning-Fast Response, Precision Down to the Micron

Next-Level Responsiveness

With a 3.8 kHz velocity loop bandwidth and a 250 μs sync cycle, our system delivers zero-lag tracking and sub-micron positioning, even at high speeds—ensuring both speed and stability for high-velocity handling, precision engraving, and more.

Powered by Advanced Control Algorithms

Intelligent path deviation prediction enables rapid yet smooth positioning, achieving nanometer-level precision for ultra-refined machining.

Vibration-Damping Innovation – Boosting Efficiency & Precision

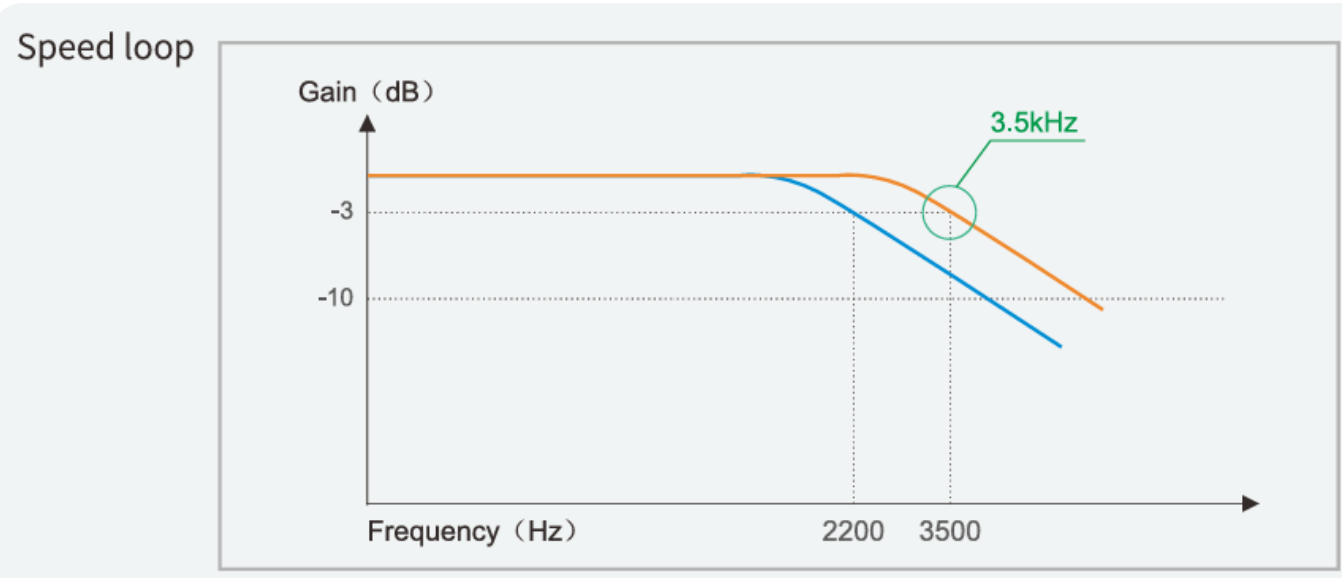

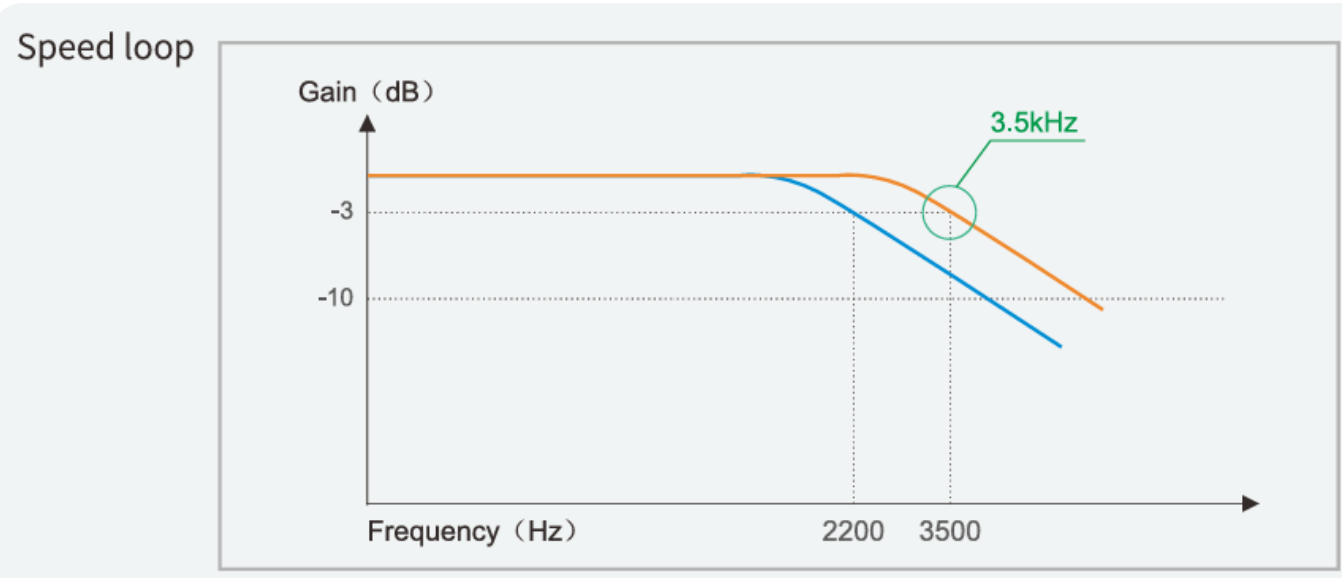

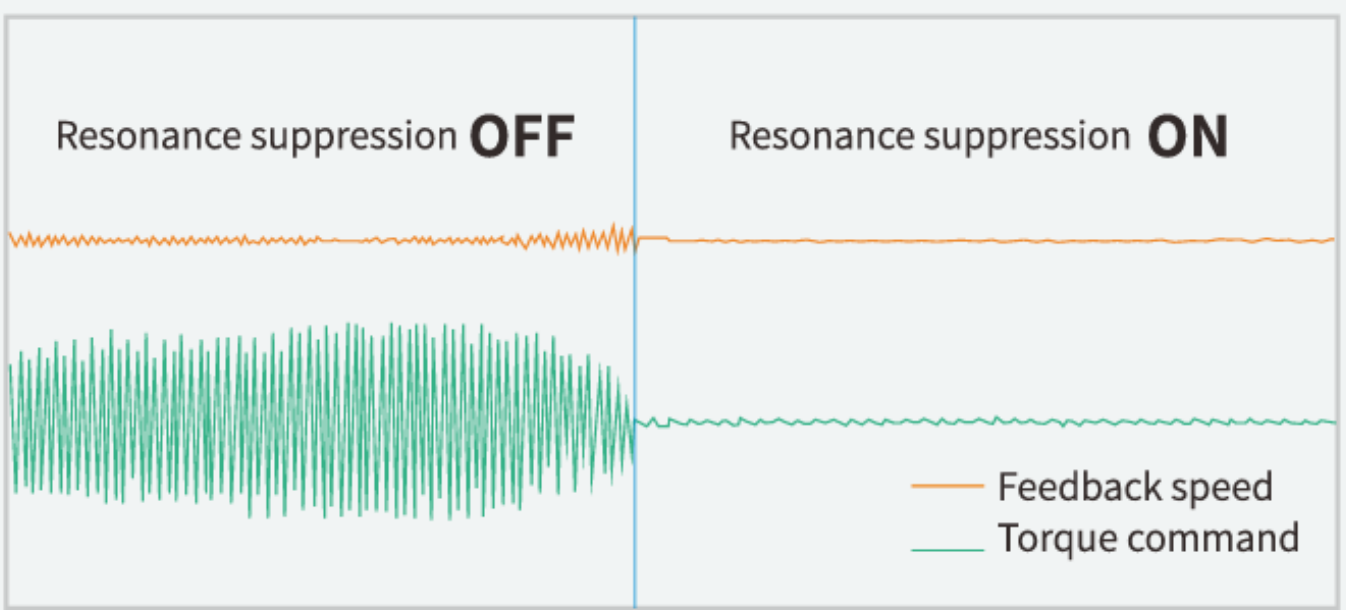

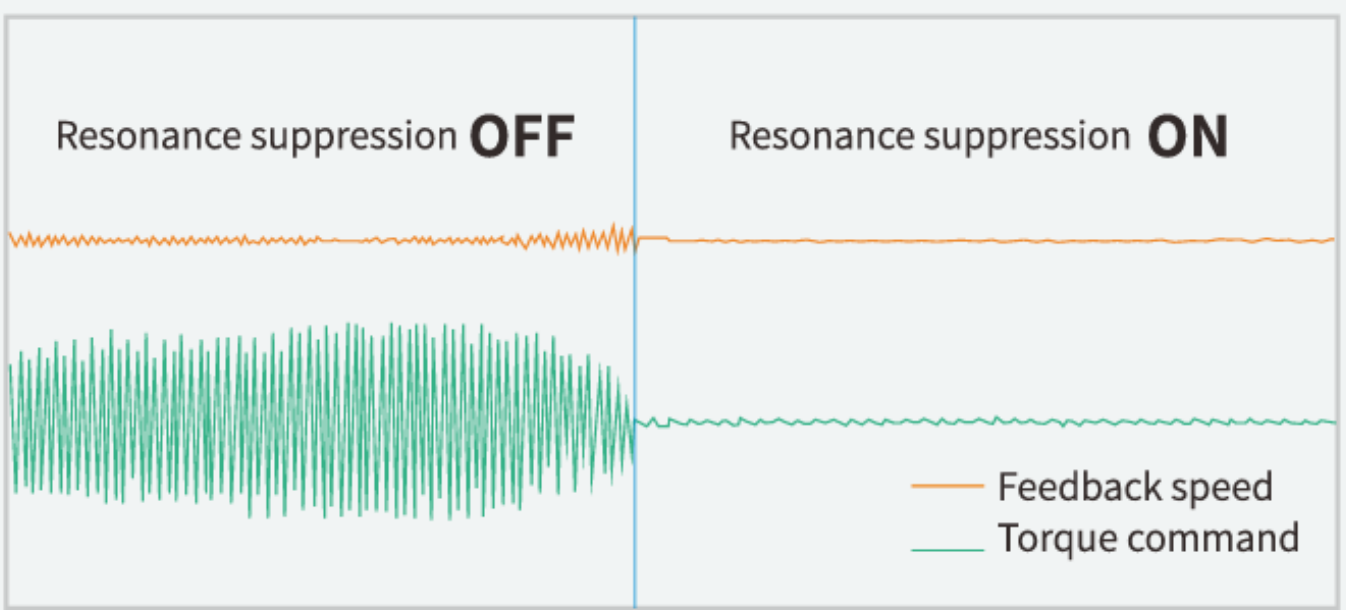

Proprietary Resonance Suppression Algorithm

- 50% higher detection accuracy

- 50% faster analysis

- Auto-scan & one-click resonance elimination

- Smoother, more precise path tracking

Advanced Mechanical End-Effector Vibration Suppression Algorithm

Effectively mitigates cantilever beam tip vibrations with reduced settling time, specifically optimized for long-stroke systems like robotic arms and gantry structures.

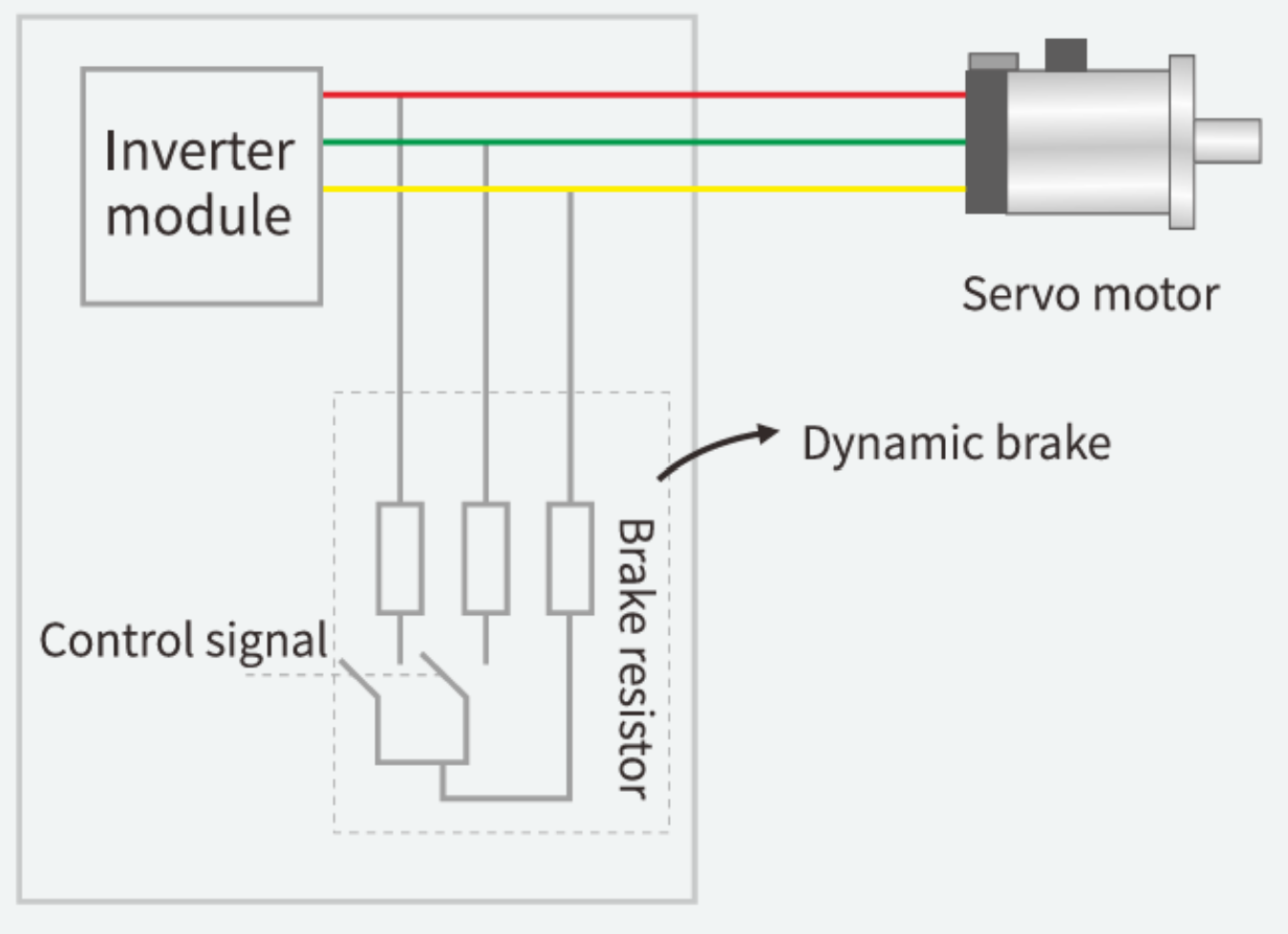

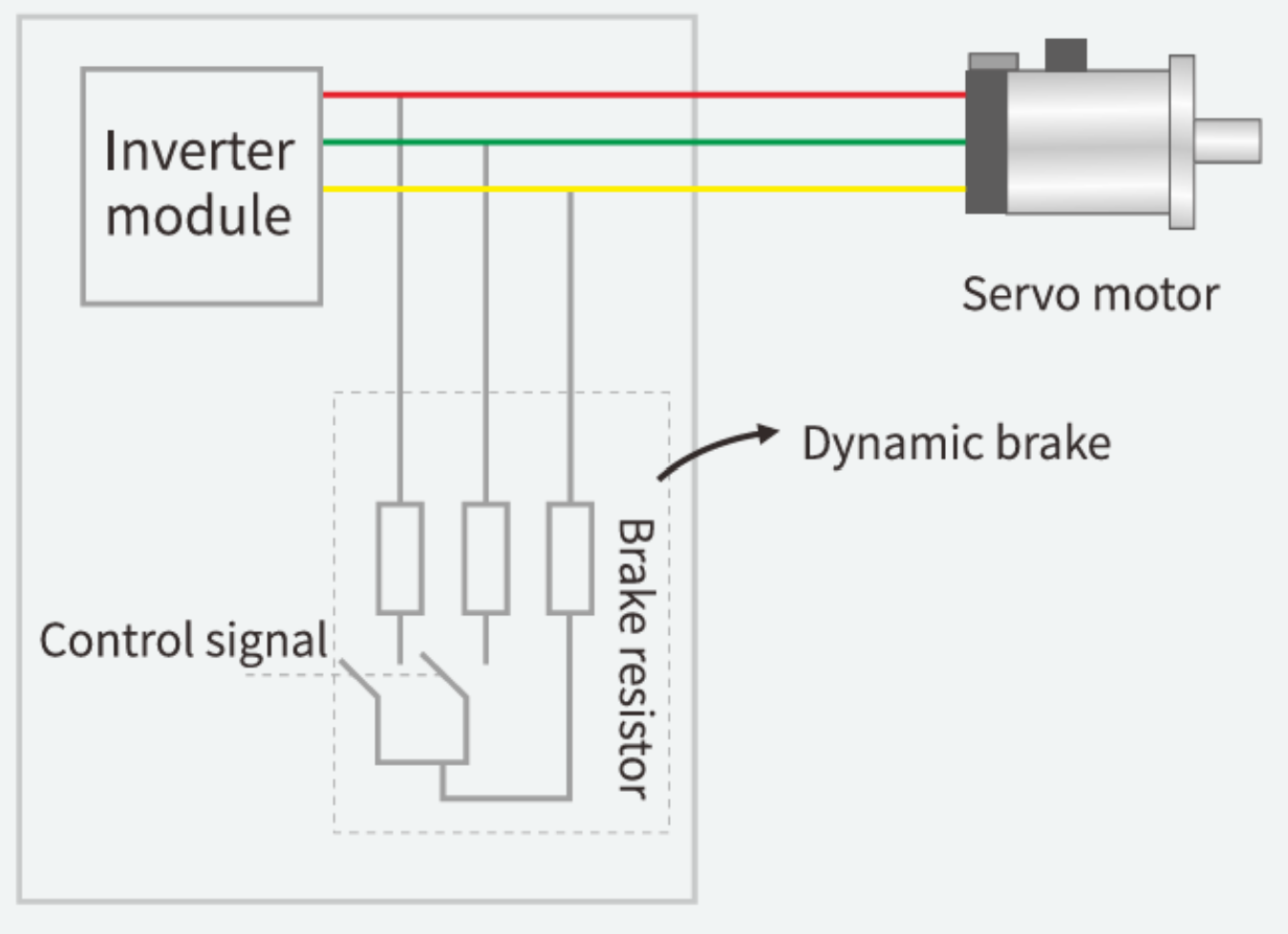

Safety & Reliability – Protecting Your Productivity Dynamic Braking

In the event of a sudden power loss or alarm, the servo cuts off (Servo OFF) with instant motor braking, ensuring both personnel and equipment safety.

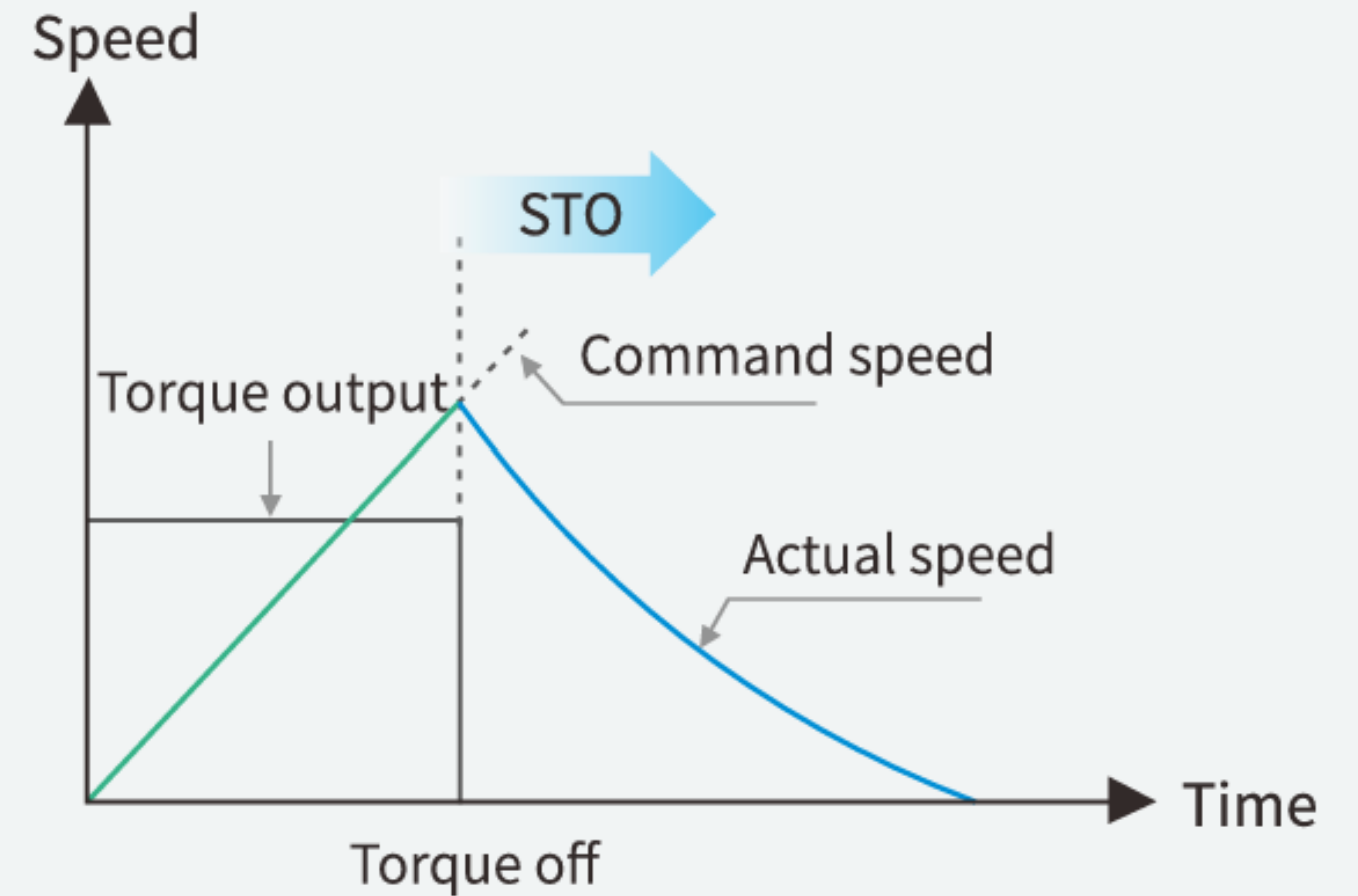

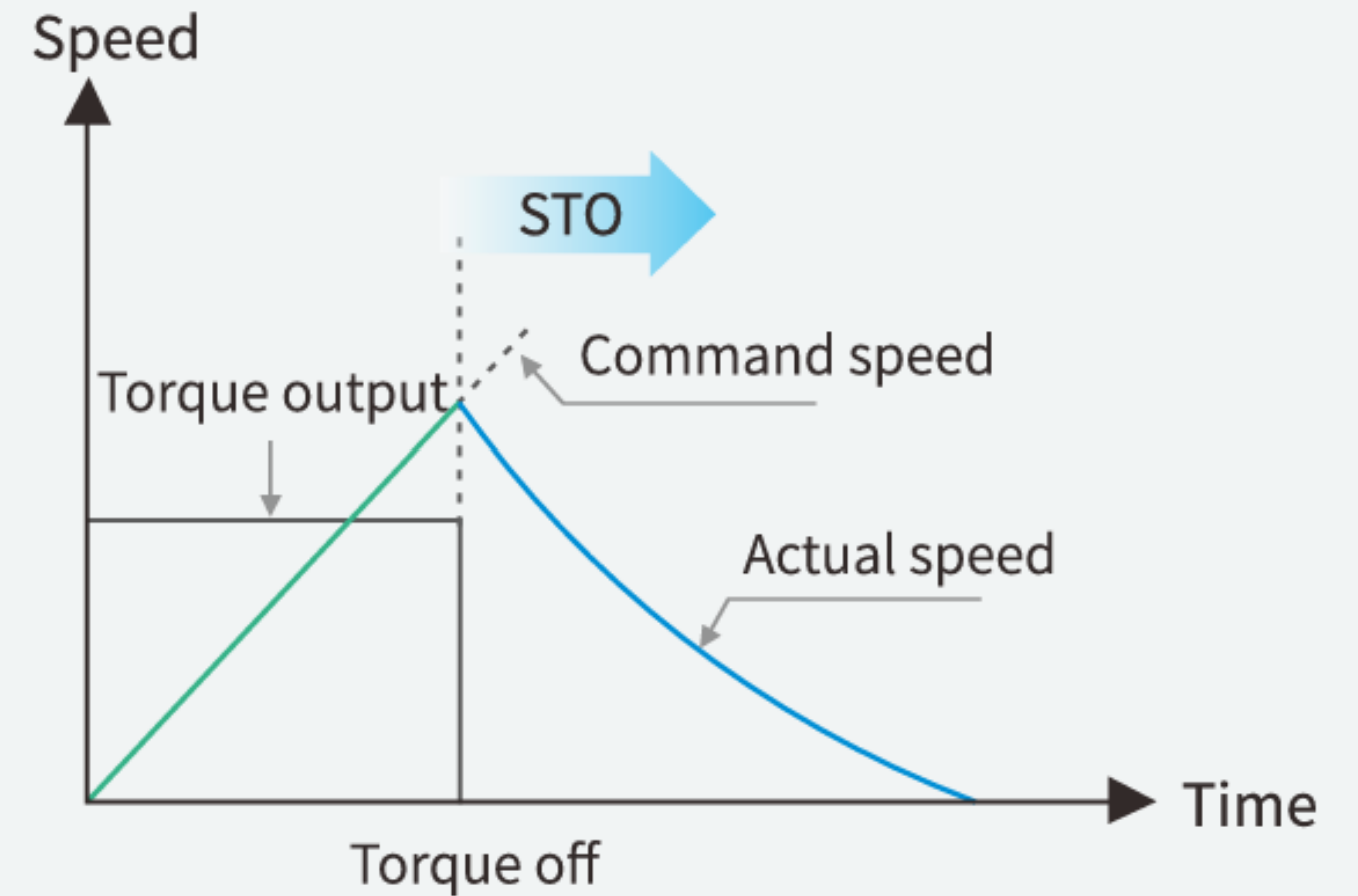

SIL3-Certified Safe Torque Off (STO)

Hardware-level power cut-off protection is triggered in emergencies, ensuring immediate motor shutdown to safeguard both personnel and machinery safety.

Multi-Circuit Protection

Equipped with ground-fault and overcurrent protection, among other safeguards, it achieves ultra-low failure rates that lead the industry.

The Ultimate Performer for Complex Applications

Type-C All-in-One Debugging

No complex adapters needed – standard Type-C interface enables plug-and-play connectivity with host systems, doubling efficiency for parameter configuration, diagnostics, and maintenance.

Innovative Gantry Synchronization Algorithm

Our next-generation algorithm ensures high responsiveness and precision synchronization between dual axes even at high speeds, significantly reducing trajectory deviation during rapid reciprocating motion. Compatible with both rigid and flexible gantry systems, it delivers flawless performance for semiconductor packaging, laser cutting, and other demanding applications.

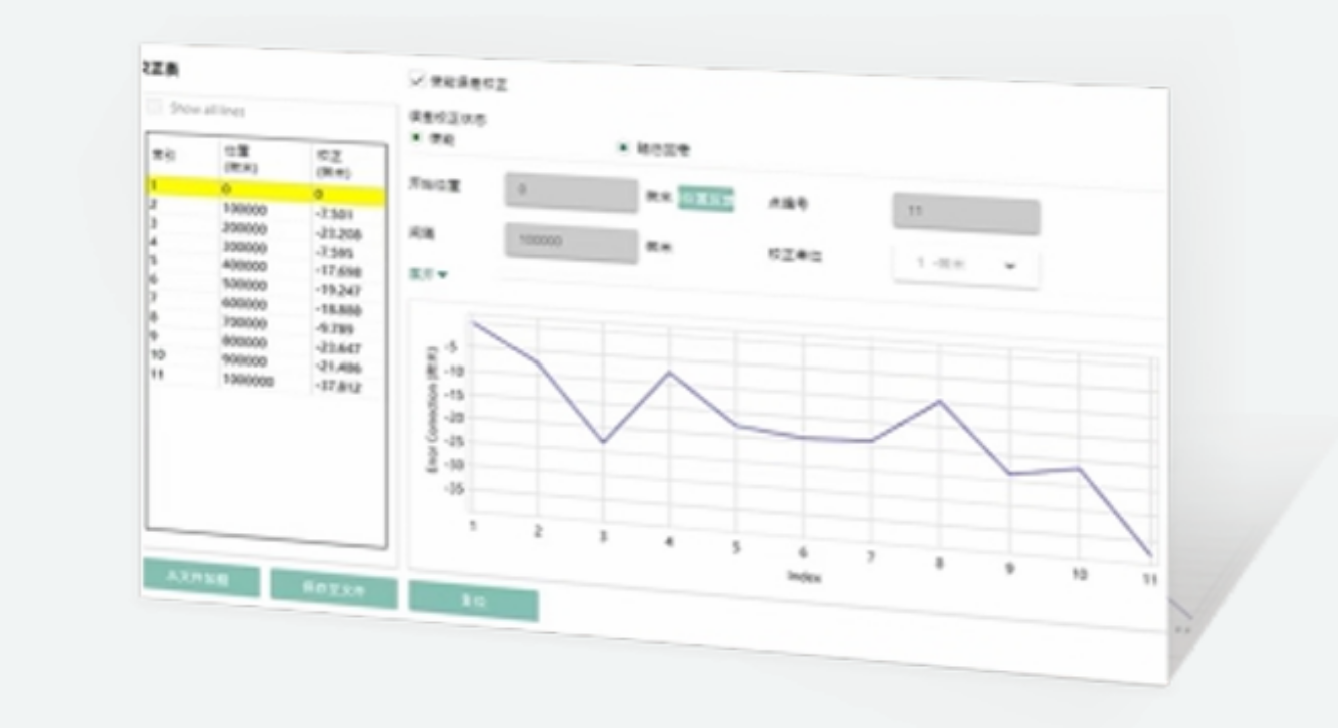

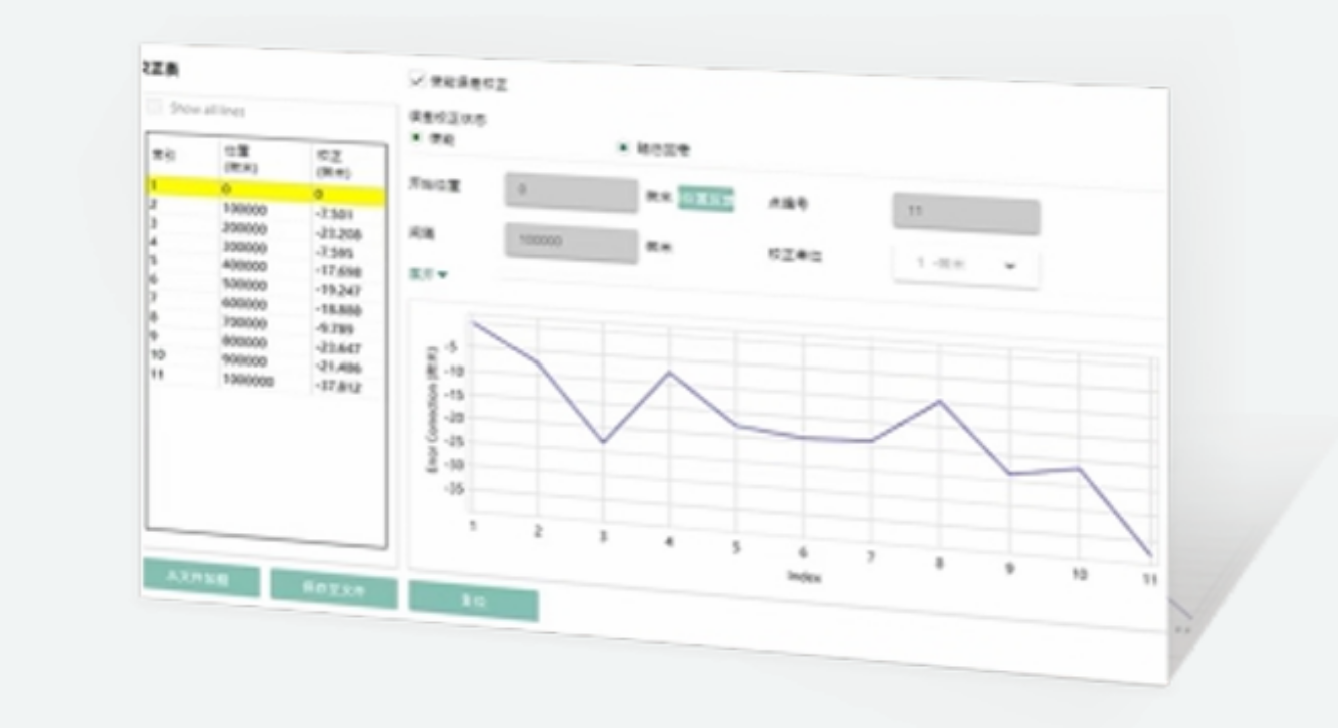

Automatic Positioning Accuracy Compensation

Real-time mechanical error correction achieves ±1μm absolute positioning accuracy, with long-term stability and zero drift – eliminating the need for manual recalibration.

The Ultimate All-Rounder – Ten Solutions in One

Packed with advanced features, including:

• Long-line drive

• Frequency division output

• Position compare output

• Probe function

• Motor temperature sampling

…and more – every function you need comes fully integrated!

There are no reviews yet.