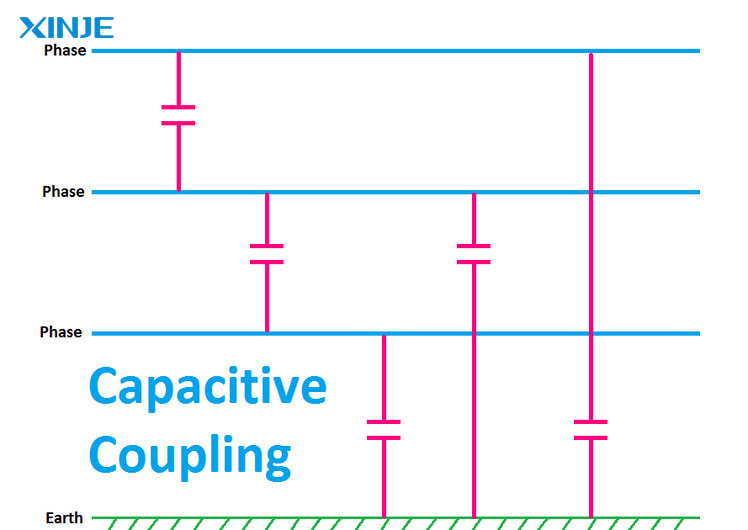

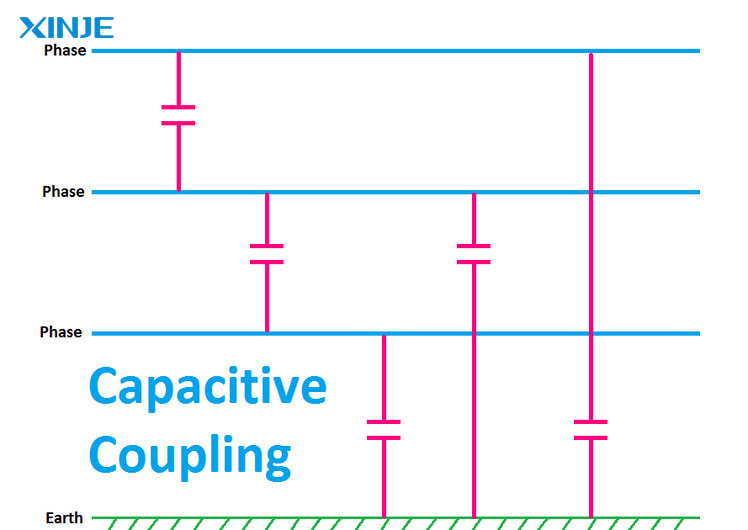

In servo systems, where all signals require high precision, the phenomenon of Capacitive Coupling can become a cause of noise and unpredictable errors. This article will help you understand the nature of capacitive coupling, its effects on servo control, as well as how to utilize or limit it effectively in real-world environments.

What is Capacitive Coupling?

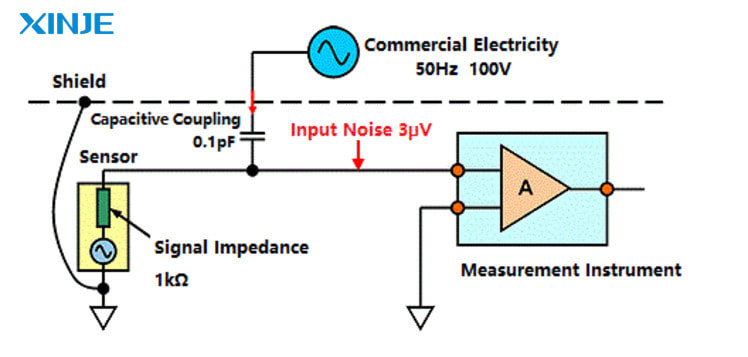

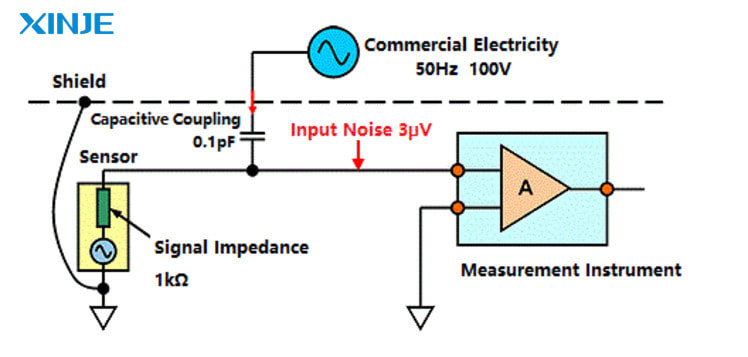

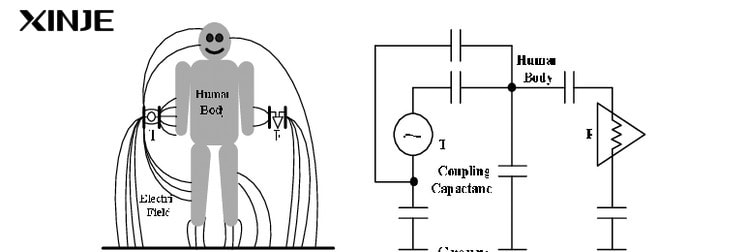

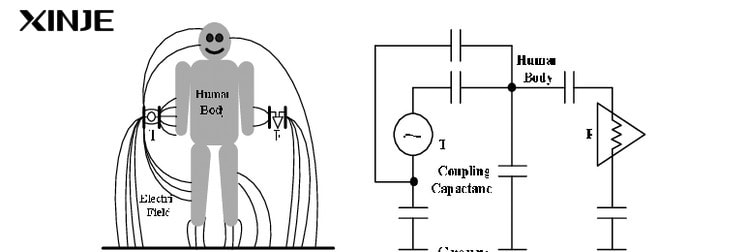

Capacitive Coupling is the transmission of electrical signals between two conductors that are not directly connected, through the static electric field generated between them. When two conductors are close together, especially the power and signal wires in a control system, the varying electric field between them will create an unwanted interference current – even without physical contact.

In servo motor systems, capacitive coupling often occurs when the motor power wire and the encoder or feedback signal wire run parallel or too close together, leading to control signal interference, position deviation, or abnormal error reporting from the driver.

How does Capacitive Coupling affect the servo system?

In servo systems, capacitive coupling is a common source of electrical noise if the wiring is not properly designed. Common effects include:

- Incorrect control signal or encoder feedback signal: When capacitive noise is transmitted to the signal wire, the feedback data is inaccurate, causing the driver to control the wrong position.

- Reduced accuracy in the control loop (position loop, speed loop): Noise interferes with the calculation process, causing unwanted delays or oscillations.

- False error reporting from the driver (noise alarm): Capacitive coupling can trigger unrealistic warnings such as overcurrent, encoder error or phase loss.

- Unexpected stoppage or slight vibration at low speed: Due to the system misunderstanding the feedback data or receiving incorrect control commands.

These errors are often difficult to detect with the naked eye but greatly affect the stability and life of the servo system.

What are the benefits of Capacitive Coupling?

Signal isolation without direct connection: Capacitive coupling allows signals to be transmitted between circuit layers or control systems without physical connections, avoiding DC noise and protecting the circuit.

- Efficient AC signal transmission at high frequencies: Capacitive coupling works well in high-frequency signal applications, reducing signal distortion and saving energy.

- Reduce background noise in amplifier circuits: In control systems or servo drivers, capacitive coupling is used to eliminate DC oscillations, helping to stabilize the signal.

- Application in non-contact sensors: This is the main principle in capacitive sensors, allowing measurement and detection of objects without mechanical contact – ideal for harsh environments or high cleanliness requirements.

- Increased safety in explosive environments: Because it does not create sparks like mechanical contacts, capacitive coupling is preferred in non-intrusive monitoring systems.

Disadvantages of Capacitive Coupling in Servo Systems

Despite its practical applications in the electronics industry, Capacitive Coupling often causes serious problems in precision control environments such as servo systems. Here are some typical disadvantages to note:

- Causes feedback and control signal distortion: When coupling occurs between the signal line and the power line, unwanted electric fields can distort the signal, causing control errors.

- Increased risk of cross-talk: Especially when signal cables run close together in a narrow space, capacitive coupling can cause one signal to “contaminate” another signal → difficult to detect, easy to miss when checking for errors.

- Causes false error alarms from the driver: Capacitive noise can trigger false alarms from the controller, causing unexpected machine stops and interrupting production.

- Reduced system performance and stability: In position and speed feedback loops, noise signals can cause the servo to oscillate slightly, respond unstablely, or lose positioning accuracy.

- Long-term impact on component life: Prolonged noise causes the control ICs, filter capacitors, or encoders to heat up, thereby reducing the durability of the entire servo system.

How to prevent noise caused by Capacitive Coupling?

To limit the negative effects of capacitive coupling in the servo system, engineers need to pay attention right from the design stage of the electrical system and installation of the wiring. Some effective solutions include:

- Isolating signal wires and power wires: Absolutely do not run encoder, feedback or PLC signal wires in parallel with the motor power supply wire. Prioritize separate wiring in separate grooves/channels.

- Use shielded cables: Signal wires should be made of copper mesh or foil to prevent interference, and ground one end according to the manufacturer’s instructions.

- Install noise filters (ferrite core, EMI filter): Install at the driver or PLC input to reduce high-frequency noise currents transmitted back into the system.

- Increase the distance between the AC power cord and signal wire: Every centimeter of distance helps significantly reduce the capacitance formed between the two wires.

- Grounding the system properly: Ensure that the entire electrical cabinet frame, equipment enclosure and shielded wire all have a common ground point, avoiding creating a mass loop that causes reverse interference.

Conclusion

In modern servo systems, Capacitive Coupling is not only a physical phenomenon but also a factor that directly affects the accuracy, stability and performance of the operation.

Understanding how capacitive coupling occurs, its advantages and disadvantages, as well as appropriate control measures will help engineers design safe, error-free and more stable operating systems. Especially in industrial production environments, preventing capacitive interference is an indispensable step in the process of deploying and maintaining servo systems.