Watchdog Timer is a mechanism that helps monitor errors and ensure that control systems such as HMI operate stably. This is an important component in automatic production lines, helping to detect and handle problems promptly. The following article by XINJE will help you understand what a Watchdog Timer is, how it works, and why it plays a key role in operating an automatic system.

What is a Watchdog Timer?

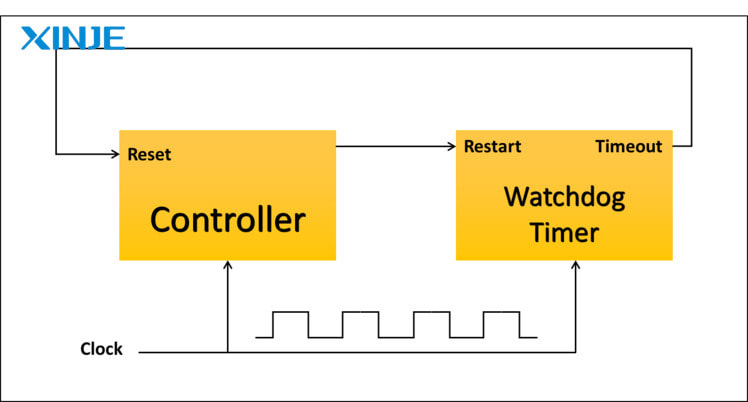

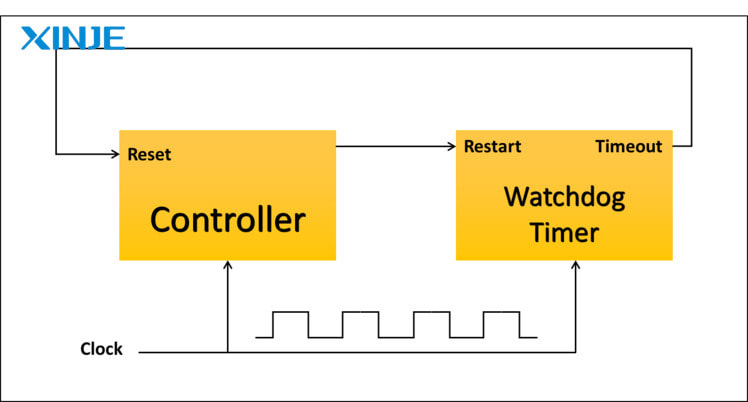

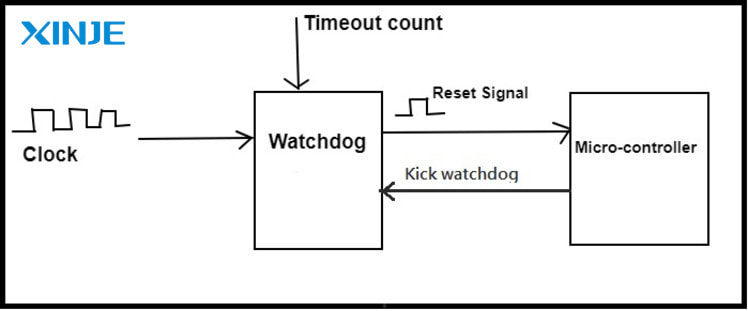

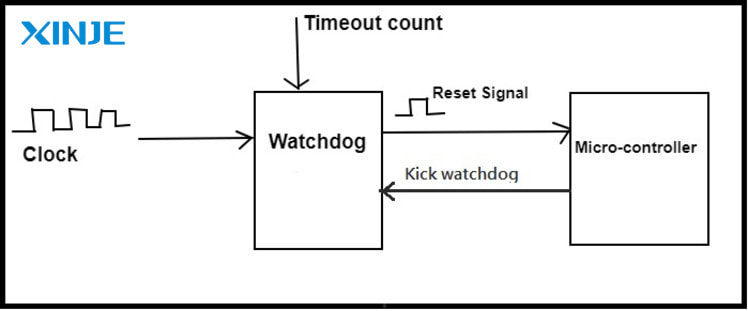

In the field of industrial automation, a Watchdog Timer is a safety mechanism designed to monitor the operation of a control system. It acts as a timer that continuously checks whether the software or control device is responding on schedule.

If the system does not respond within a preset period of time, the Watchdog Timer will automatically trigger a recovery action, such as resetting the system or returning the device to a safe state.

What is the role of a Watchdog Timer in an HMI system?

In an industrial environment, where the system needs to operate continuously and accurately, an HMI hang or loss of response can directly affect the entire production line.

At that time, the Watchdog Timer acts as a monitoring mechanism to help detect abnormal situations early and handle them promptly, to ensure the system operates stably and safely. The Watchdog Timer is programmed to continuously check whether the HMI is operating properly.

If the system does not send a “refresh” signal at the specified time, the Watchdog will consider it an error and trigger a recovery action, such as restarting the HMI software, resetting the system, or sending a warning to the operator.

This mechanism helps prevent the HMI from “freezing” without anyone noticing, thereby minimizing downtime, limiting data errors, and improving the reliability of the entire chain.

How to monitor HMI system errors with Watchdog Timer?

Monitoring HMI system errors with Watchdog Timer is done through a cyclic timer mechanism.

During normal operation, the software or control device will periodically send a “reset” signal (reset timer) to notify that the HMI is still operating stably.

If within a predetermined period of time, the Watchdog does not receive this signal, it will consider this as a sign that the HMI is frozen, unresponsive or has a software problem. At this time, the Watchdog Timer will automatically:

- Restart the HMI or related software.

- Activate local or remote alarms.

- Put the system into safe mode to avoid damage to the line.

What benefits does the Watchdog Timer bring to the business?

Not only is it a fault monitoring tool, the Watchdog Timer also brings many practical values to operations in industrial environments. Below are the outstanding benefits that the Watchdog Timer brings in actual operations.

- Timely error detection and handling: The Watchdog Timer helps detect problems such as HMI hangs, PLCs do not respond, or programs operate incorrectly. This early detection minimizes downtime and prevents problems from spreading throughout the line.

- Increased reliability for the entire system: With its continuous monitoring mechanism, Watchdog ensures that every component in the system is always monitored and ready to self-recover when a fault occurs.

- Automated safety processes: When a fault occurs, Watchdog can be programmed to perform a safety action, such as disconnecting, putting the device into “safe mode” or activating the warning system.

- Reduced dependence on manual intervention: Thanks to Watchdog, the system can automatically detect and recover from faults without waiting for operator intervention, thereby saving time, manpower and minimizing operational risks.

What are the common errors related to the Watchdog Timer in HMI?

Although it plays an important role in monitoring and ensuring the stability of the control system, Watchdog Timer, if not configured or operated properly, can still cause some common errors.

These errors not only affect the performance of the HMI but also potentially disrupt the entire production line. Below are some common problems when deploying Watchdog Timer in practice.

- The system restarts continuously due to Watchdog Timer: One of the common errors is that the Watchdog Timer is configured with a wait time that is too short, causing the system to not send the “refresh” signal on time.

- Loss of response between HMI and PLC: If the HMI’s communication signal with the PLC or control device is interrupted, the Watchdog Timer may mistake this for a system error and automatically reset. This situation often occurs when there is signal interference, loose connection cables, or improper communication configuration.

- Watchdog Timer is not configured or disabled: In some older systems or due to programming errors, the Watchdog Timer may be disabled or misconfigured, making it unable to properly detect system hangs.

- Software error or incomplete loop: If the control program has a logic error (e.g., the loop does not end), the Watchdog refresh signal will not be sent in time, resulting in the system being reset even if there is no hardware problem.

Conclusion

In modern industrial environments, where control systems and operator interfaces such as HMIs must operate continuously with high precision, Watchdog Timer becomes an indispensable monitoring mechanism.

From early detection of software errors, ensuring HMIs are always responsive, to supporting monitoring of signals from PLCs, Watchdog helps businesses maintain stable and safe production processes.

Although only a small component in the entire system, Watchdog Timer brings great value in reducing downtime, preventing serious incidents and increasing operational reliability.

For factories moving towards complete automation, properly configuring and deploying Watchdog is a necessary step to improve efficiency and continuity in production.