What are the HMI Errors? Human-machine interfaces (HMIs) are a critical component of industrial automation systems, allowing operators to interact with machines through graphical displays and input devices. While reliable, HMIs are not immune to failure. Over time, they can develop issues that hinder productivity, disrupt communication with the PLC, or cause system-wide failures. Understanding common HMI errors and how to resolve them promptly can minimize downtime, prevent costly repairs, and improve operational efficiency.

In this article, we will explore four common types of HMI errors, ranging from touchscreen failures, communication failures to hardware and software failures.

Touch Screen Problems

HMI touchscreen errors

Touchscreen problems are among the most frequently reported issues in HMIs. They often result in poor usability and can seriously affect the ability to control operations. Typical touchscreen failures include:

- Unresponsive or slow-responding screens

- Ghosting occurs when input is registered without actual contact.

- Cracks or physical damage to the display

- Backlight failures on the display

These failures are severe and should be corrected by operators or reported to warranty units for timely troubleshooting.

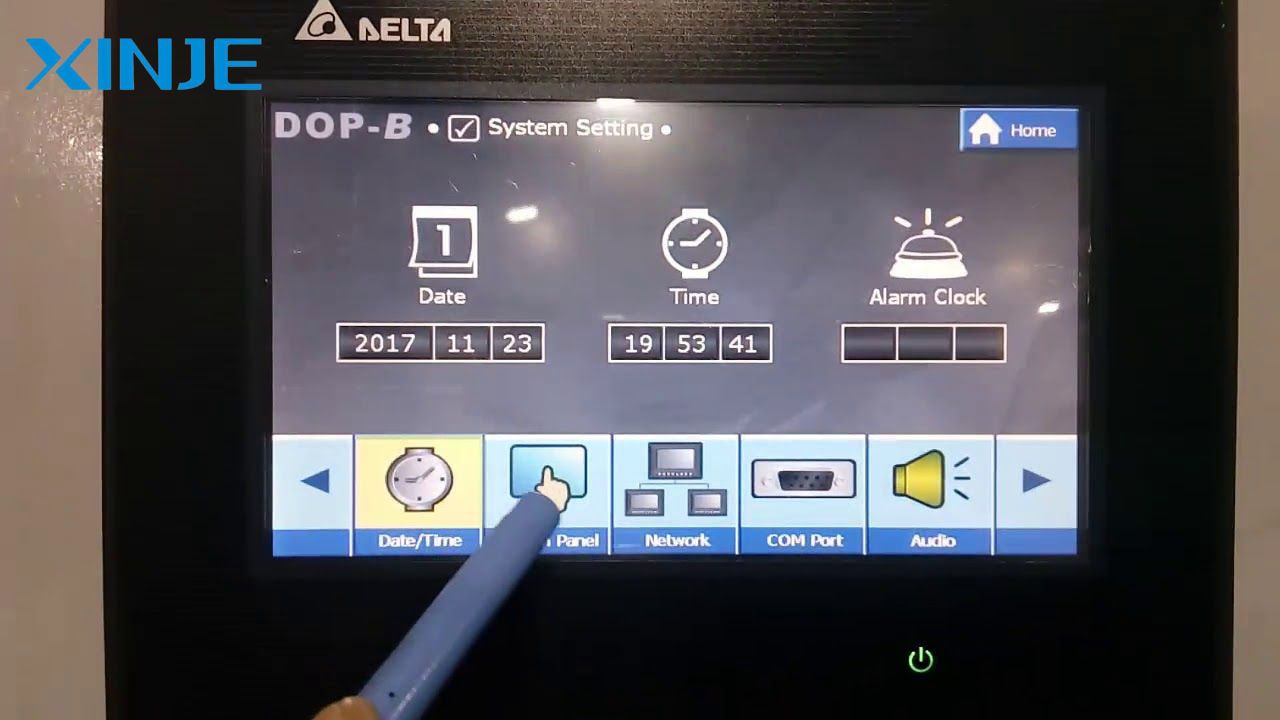

How to Fix Touchscreen Problems?

Some Specific Solutions for Basic HMI Display Faults

- Perform display calibration: Most HMI systems allow for periodic calibration through system settings. Out-of-line inputs can often be corrected through manufacturer-supplied software calibration tools.

- Clean the display properly: Dirt, oil, or moisture buildup can affect capacitive touch functionality. Use a microfiber cloth and isopropyl alcohol to gently clean the display.

- Check for physical damage: If the touch panel is cracked or broken, it needs to be replaced. Always turn off the device before disassembling or inspecting internal components.

- Update the firmware: Occasionally, touch sensitivity issues are caused by outdated firmware. Visit the manufacturer’s website for the latest updates compatible with your model.

Communication Errors with the Device

Errors

Communication problems between HMIs and connected devices such as PLCs, SCADA systems, or sensors are common in automation operations. These problems can cause production stoppages and process disruptions if not detected and resolved quickly. Some of the main symptoms include:

- Lost or no communication with the PLC

- Inconsistent data display

- Timeout errors or disconnect messages

- Incorrect protocol configuration

- IP address conflicts on the network

How to troubleshoot device communication problems?

- Verify cable and port integrity: Use a tester or replacement cable to rule out damaged Ethernet or serial lines. Check for bent or corroded pins on the connector.

- Check protocol settings: Make sure the selected communication protocol (Modbus, OPC UA, Profibus) matches the device configuration. If the settings do not match, this is a common oversight.

- Restart the device: Sometimes, re-powering both the HMI and PLC can re-establish lost communication.

- Use Diagnostic Tools: Many HMI software suites include diagnostic utilities that display active connections, error logs, and packet statistics to help pinpoint the problem.

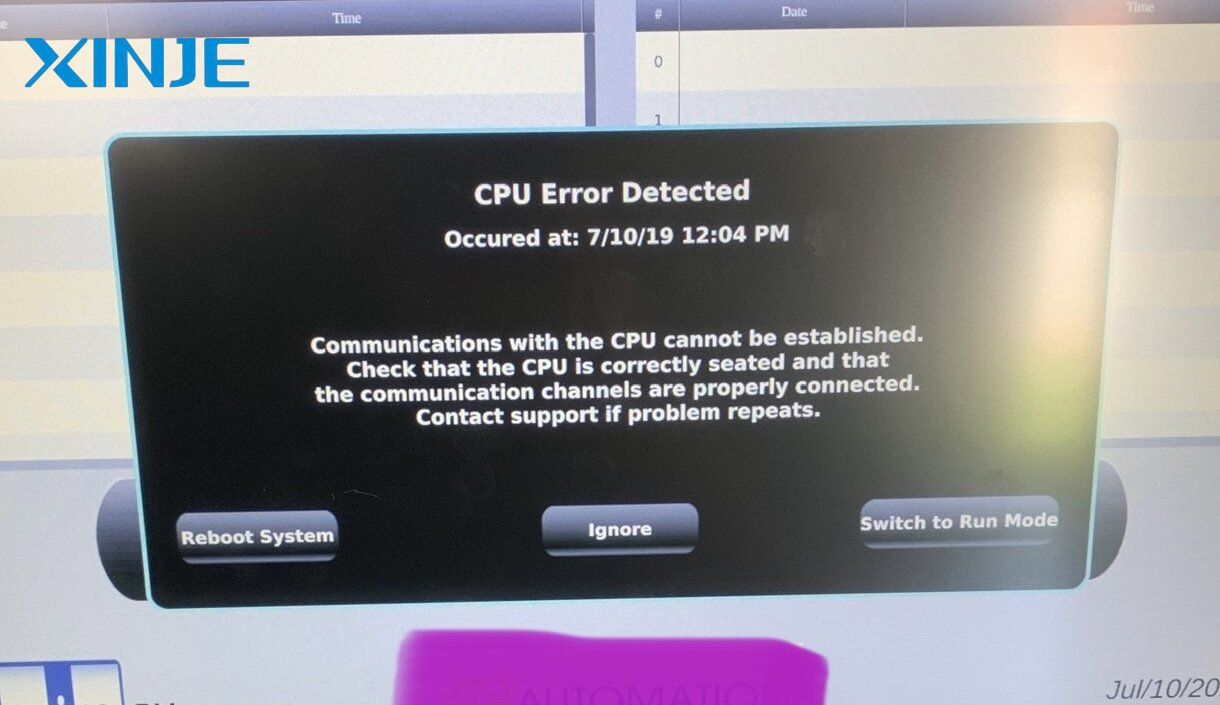

Hardware Errors

Hardware errors on HMI

Hardware failures are failures in the physical components of the HMI system, such as physical buttons, off-screen touch, etc. These problems are often more serious and may require part replacement or professional repair. Some common hardware failures include:

- A faulty power supply or internal power regulator

- A faulty I/O port or expansion module

- Faulty CPU board

- Failed cooling fan or overheating

- Corroded ports or connectors due to environmental exposure

How to troubleshoot hardware failures?

- Visual inspection: Check for burned components, swollen capacitors, or signs of water ingress. Unusual odors or noises often indicate deeper hardware problems.

- Measure the power supply voltage: Use a multimeter to verify that the device is receiving a stable and correct voltage. Replace the power adapter if necessary.

- Replace damaged components: If any components or fuses at the board level are visibly damaged, replace them with OEM parts. Always follow ESD precautions when handling internal circuitry.

- Contact manufacturer support: For hardware that is still under warranty or has complex issues, contact the manufacturer’s technical support for an RMA or repair option.

Software Errors

HMI Software Errors

Software errors are less common but can also be disruptive. These issues often stem from incorrect programming, version mismatches, or user errors during configuration.

System crashes or HMI freezes

- Display is unresponsive during certain functions

- Incorrect alarm configuration

- Runtime errors or licensing issues

- Outdated software or corrupt configuration files

How to fix software errors?

- Check error logs: Review the system log files to determine which process or script is causing the problem. Most HMI programming environments provide a detailed debug view.

- Update HMI software: Install the latest software updates and patches to eliminate known bugs and compatibility issues.

- Restore backup configuration:If the configuration file is corrupted, restore from the most recent backup. For this reason, regularly scheduled backups are essential.

- Validate alarm logic: Incorrect alarm or interlock logic can cause excessive alarms or failure to trigger alarms. Review alarm conditions in the development environment.

Conclusion

The process of operating an HMI system will inevitably involve risks to the equipment. Therefore, to ensure smooth and stable operation, regular inspection, proactive maintenance, proper configuration, and updating of software and firmware releases are important measures for operators to minimize these errors.

Whether you are a technician, plant manager, or automation engineer, having a structured troubleshooting approach will help you quickly identify problems and implement effective, timely solutions.