What is the position control of the servo motor? Position control refers to the method of precisely directing a servo motor’s movement to a specific position. This process is fundamental in various automation tasks that require exact positionings, such as packaging, robotics, and material handling.

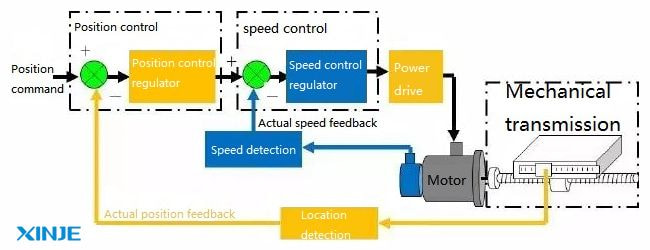

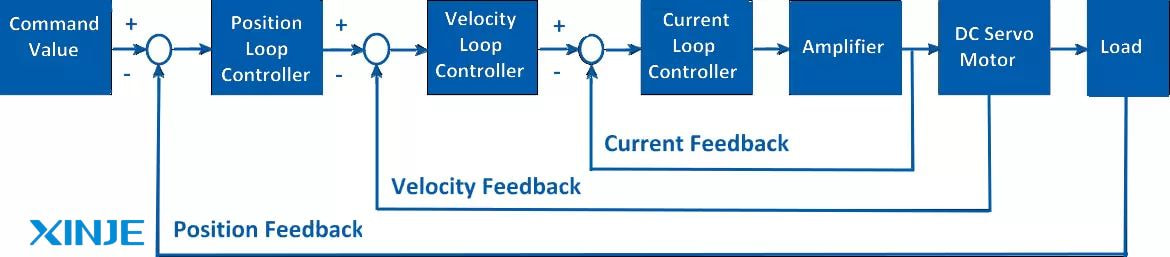

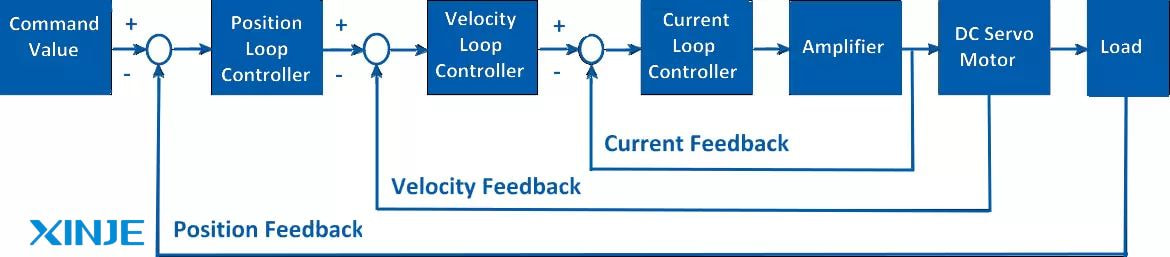

At the heart of position control lies a feedback-driven mechanism that continuously monitors and adjusts the motor’s position in real time. This ensures the load reaches and maintains the desired location without overshooting or lagging. To visualize how this works, engineers often use a position control diagram, a schematic representation of the servo system and its control logic. These diagrams are essential for understanding and troubleshooting servo motor behavior in automation applications.

How do servo positions work?

Servo motors operate on the principle of closed-loop feedback. The system continuously monitors the output and adjusts the input signal accordingly. Here is a step-by-step diagram of how servo position control works:

- The command signal is the process that begins with a target position input command set by the user or controller. This input is usually in the form of a voltage signal, pulse width, or digital data from a PLC or motion controller.

- The controller compares the desired position with the actual position reported by the feedback device. It calculates an error signal, which is the difference between the two values.

- The Servo Drive (Amplifier) generates an error signal that is then sent to the servo drive, which adjusts the motor voltage or current to correct any deviation from the desired position.

- Feedback system: The encoder or decoder continuously monitors the shaft position and sends this information back to the controller, closing the loop and allowing real-time correction.

How to control the position of a continuous servo motor?

Continuous rotation servo motors differ from standard position servos in that they can rotate freely in both directions without any pre-set limits. While this provides more flexibility, it also poses challenges, and to control the position of a continuous servo motor, the following factors must be considered:

- Using External Feedback: Unlike standard servo motors, continuous servos do not stop at a defined angle. Therefore, the technician needs to integrate with some other devices, such as Rotary Encoders, Optical Sensors, and Hall Effect Sensors, to help track the actual position, allowing the controller to determine how far the motor has moved.

- Applying Pulse Width Modulation: PWM is used to adjust the speed and direction of the motor. In a continuous servo, PWM will support precise direction and speed control, so users can implement a form of position control even in continuous rotation situations.

- Application-based adjustment: Depending on the application, such as conveyor belt, robot wheel…, the position tracking can be relative (from the starting point) or absolute (specific coordinates). From there, the technician will adjust the control process accordingly.

How do I stop a servo from moving?

Stopping a servo motor correctly is just as important as moving it. Depending on the requirements of the system, you have several methods to stop the servo movement:

- Command stop: The simplest way is to send a target position equal to the current position. This will command the servo to hold the position.

- Use Torque Hold: Most servo motors are designed to hold position when no load is applied. When power is maintained, the servo will generate torque to counteract any external force that might try to move it.

- Emergency stop (E-Stop): For safety-critical applications, a hardware-based E-stop can immediately cut off the drive power or disengage the braking system. However, this method can result in an uncontrolled stop.

- Servo Brake: Some servo motors are equipped with electromechanical brakes that lock the shaft when power is lost. This is especially useful for vertical applications such as elevators or robot arms.

- Disable PWM or Controller Output: You can programmatically stop the servo by disabling the PWM signal or turning off the control output. This method is software-controlled and is used in less time-sensitive situations.

Conclusion

In automation systems, servo position control is a foundational technology that ensures motion is both accurate and repeatable. Whether you’re working with standard or continuous servo motors, understanding the position control diagram helps visualize the complete control loop from input to output and feedback to correction.

Stopping a servo motor depends on your method of control, ranging from command-based stops to mechanical brakes. By mastering position control in servo systems, engineers can build high-performance automation systems that deliver precision, safety, and efficiency.