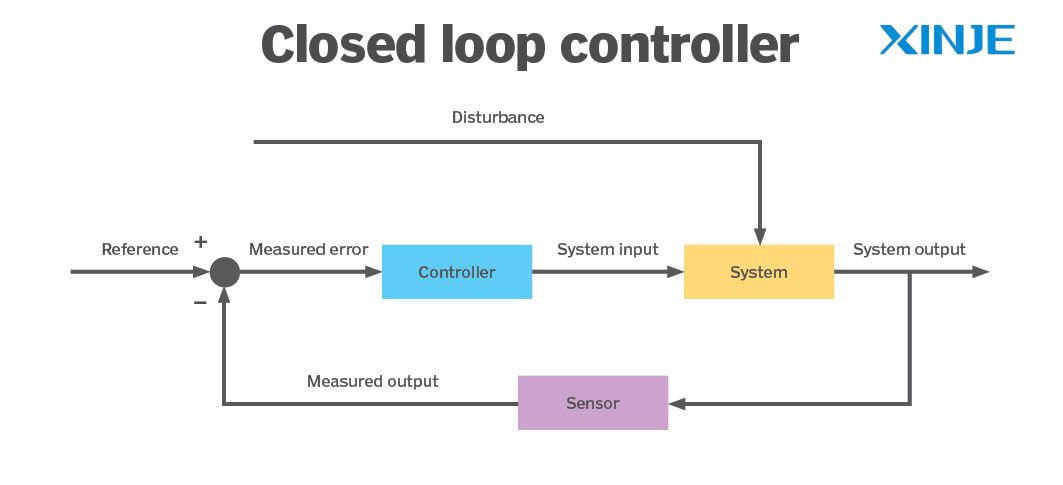

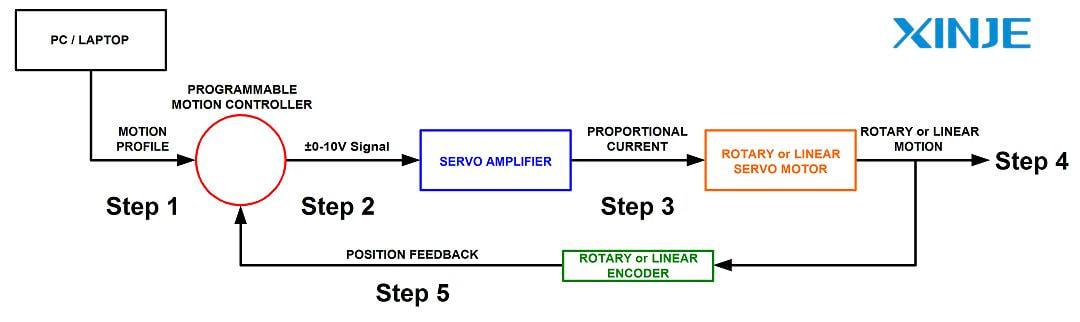

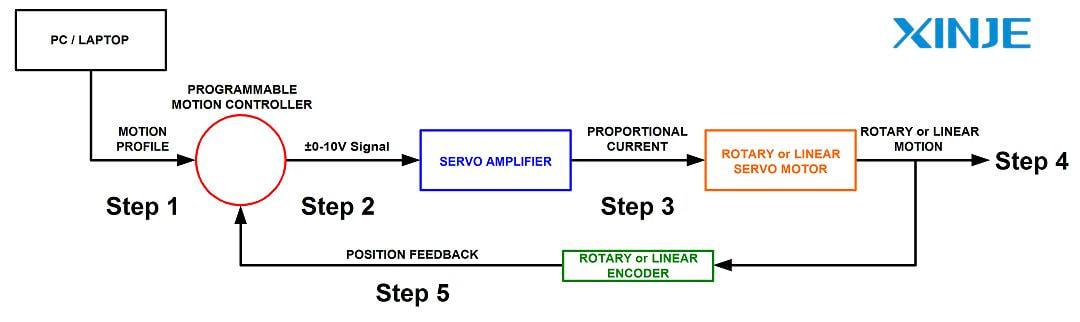

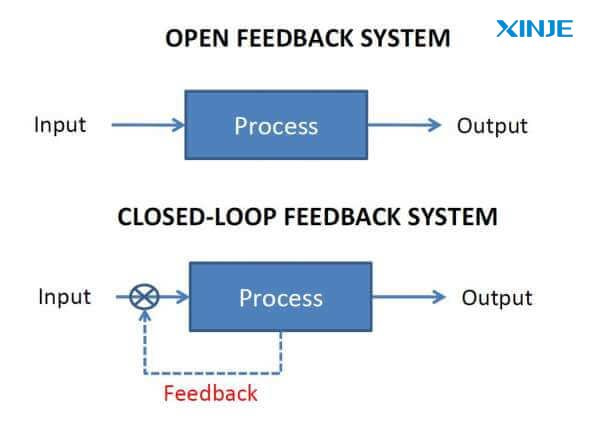

What is a closed-loop servo system? A closed-loop servo system is an advanced control mechanism that delivers high accuracy by continuously monitoring and correcting its output based on real-time feedback. Unlike its open-loop counterpart, a closed-loop system ensures that the desired motion, speed, or position is precisely achieved, making it ideal for applications that demand exceptional reliability and performance.

In simple terms, a closed-loop servo uses feedback to compare actual output with the intended command. If any deviation is detected, the system instantly adjusts to minimize the error, ensuring optimal control and consistency.

What is the purpose of a closed-loop system?

The primary goal of a closed-loop system is to maintain precise control of mechanical movements by minimizing errors through continuous feedback. This makes it valuable in environments that require high precision, repeatability, and responsiveness.

- Error correction: Detect and correct deviations in position, speed, or torque in real time.

- High accuracy: Maintain tight control of output, especially in dynamic applications.

- Stability: Reduce oscillations and overshoots, ensuring smoother system operation.

- Efficiency: Optimize energy usage by providing only the corrections needed.

- Safety: Prevent mechanical failure by monitoring and correcting abnormal operations.

In automation systems, the ability to monitor performance and adjust operation instantly gives closed-loop servos a significant advantage over open-loop alternatives, especially in complex or sensitive tasks.

What are the applications of a closed-loop system?

Closed-loop servo systems are widely used in industries that require precise motion control, speed regulation, or torque management. These systems play a vital role in modern manufacturing, robotics, and automated machinery, with some common applications including Industrial Automation, Robotics, Packaging and Labeling Machines, and Printing and Textile Machinery.

- Industrial Automation: In CNC machines, robot arms, and conveyor systems, closed-loop servos ensure tools move to the correct position at the required speed, improving consistency and reducing scrap.

- Robots: Robots rely on feedback to control coupling, orientation, and path correction. Closed-loop systems allow for smoother and safer interactions with people and objects.

- Packaging and Labeling Machines: Fast, repetitive tasks such as sealing, cutting, or labeling benefit from closed-loop systems, which maintain accuracy despite changing speeds or load conditions.

- Printing and Textiles: Maintaining print alignment or controlling fabric tension is made possible by real-time adjustments from feedback sensors.

- Medical Devices: From surgical robots to imaging systems, precision is critical. Closed-loop control ensures reliable and repeatable performance.

In any application where speed, torque, or position control needs to be maintained dynamically, closed-loop systems are the optimal solution.

What sensors are used in a closed-loop?

Sensors are considered the backbone of closed-loop feedback. Without accurate sensors, it is impossible to have accurate and reliable calibration of the system. Some common types of sensors used in closed-loop feedback are Rotary Encoders, Decoders, Linear Encoders,…

- Rotary Encoders: Encoders are the most commonly used sensors in servo systems. They convert the shaft’s position into a digital signal. With two main classifications, incremental encoders and absolute encoders, they can provide accurate position values, even during power outages.

- Decoders: Decoders are analog devices that measure angular position. They are highly durable and ideal for harsh environments.

- Linear Encoders: Measure linear displacement, often used in precision machining or coordinate measuring machines (CMMs).

- Current and voltage sensors will help monitor the torque and power consumption of the motor, allowing for protection and optimization.

Choosing the right sensor depends on factors such as required resolution, environmental conditions, cost, and the speed of your system.

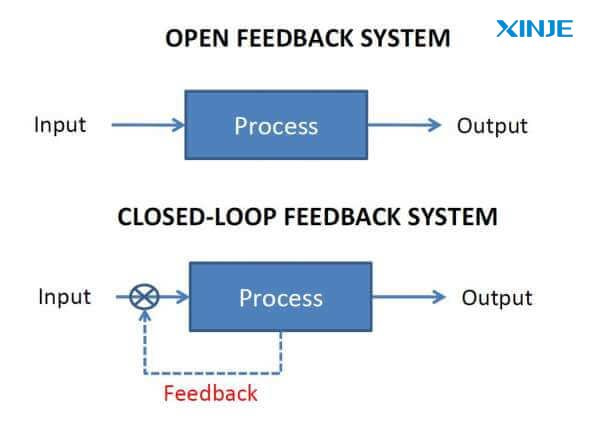

What is the difference between open and closed-loop servos?

When selecting a servo system for automation tasks, it is essential to understand the core differences between open-loop and closed-loop configurations. While both are used to control motors and manage motion, they differ significantly in how they handle system accuracy, response, and stability. Some of the obvious differences that operators need to be aware of include:

| Feature | Open-Loop Servo | Closed-Loop Servo |

| Accuracy | Low to Medium | High |

| Cost | Lower | Higher |

| Complexity | Simple | Complex |

| Error Correction | Not possible | Real-time correction |

| Reliability | Less reliable under variable loads | Highly reliable |

| Common Applications | Basic conveyor systems, fans | Robotics, CNC, precision machinery |

In summary, the choice between open-loop and closed-loop servo systems depends on the level of accuracy, reliability, and adaptability required by your application. Open-loop systems may be adequate for simple, low-cost tasks where accuracy is not critical. However, for high-performance environments that require real-time feedback, error correction, and consistent operation, closed-loop systems provide the optimal solution.

Conclusion

Closed-loop servo systems represent the pinnacle of precision control in modern automation. Through continuous feedback and real-time correction, these systems ensure that the desired motion, speed, or position is executed with exceptional precision.

Whether you are designing a robot arm, automating a CNC machine, or optimizing a packaging line, understanding how closed-loop systems work and their benefits over open-loop configurations will help you choose the right solution for your automation goals.