Higher precision, stable laying, and convenient operation

Multi-thread cutting machine is a key equipment in the manufacturing process of core device substrates in industries such as IC (integrated circuit), IT (information technology), PV (photovoltaic), etc. It has the advantages of high efficiency, high production capacity, and high precision, and is currently the most widely used equipment for cutting hard and brittle materials.

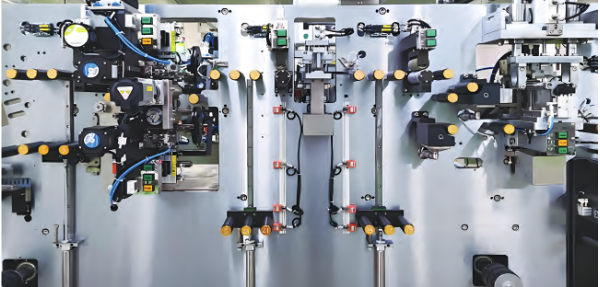

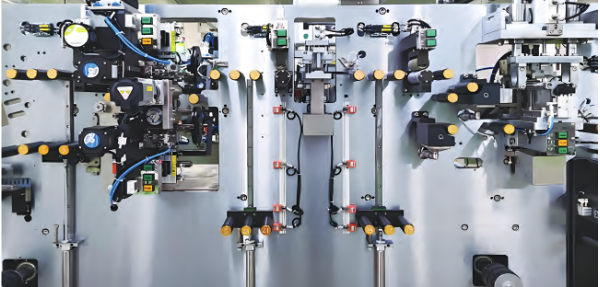

Equipment Introduction

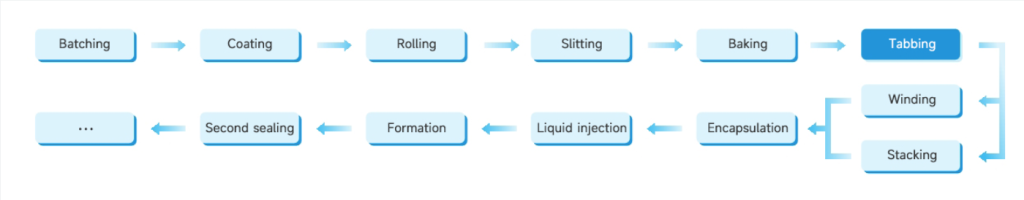

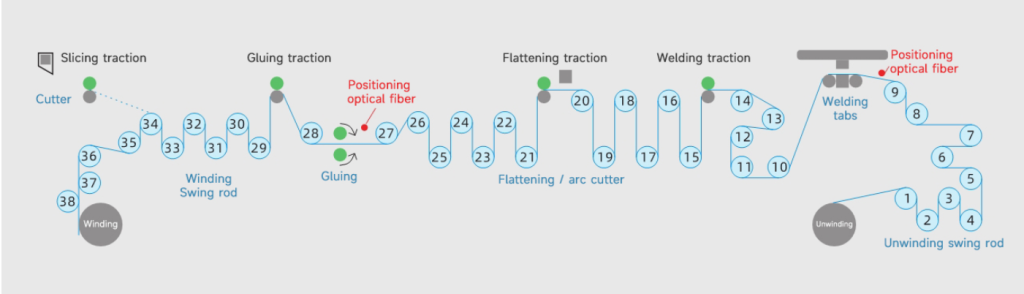

The function of the tabbing machine is to weld tabs on the electrode plates and attach insulating tapes at the positions where the tabs are welded and the blank areas of the electrode plates, providing production materials for the next process. The main models include 2-channel glue, 4-channel glue, 6-channel glue, 8-channel glue, and the double-welding and double-tab attaching model. In addition, according to different material receiving methods, it is further divided into winding and slicing.

Process principle

The tabbing machine is mainly divided into 3 stations: welding tabs, gluing, and material receiving.

Weld Tabs

Apply Adhesive

Collect Materials

Scheme advantages

Good unwinding stability

Good unwinding correction performance

High taping accuracy

Stable operation

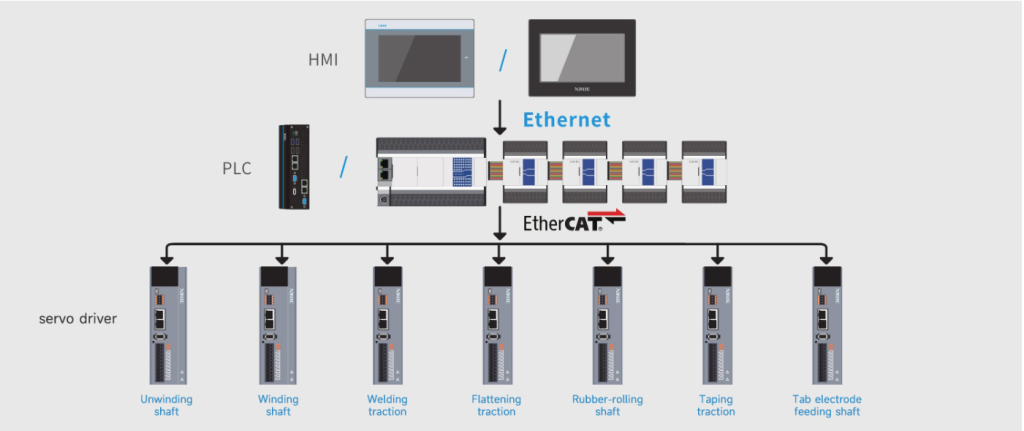

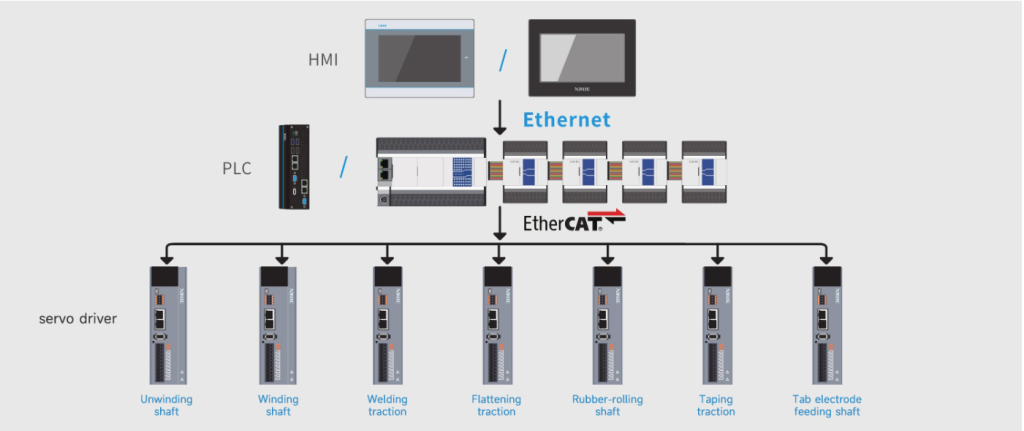

System topology