What is an encoder? An encoder is a sensing device that converts motion or position into an electrical signal. This signal is interpreted by control systems, such as Programmable Logic Controllers (PLCs) or servo drives, to determine the position, speed, direction, or quantity of a mechanical part.

Encoders play a crucial role in closed-loop control systems by providing real-time feedback on motor shaft position, linear motion, and rotational speed. They are widely used in robots, CNC machines, elevators, conveyor systems, and other applications.

What is the role of the encoder?

The primary role of encoders is to provide feedback to control systems in an automation environment. This feedback is critical to maintaining precise control over a variety of functions, including:

- Position monitoring: Encoders allow the system to know exactly where the motor or actuator shaft is at any given moment.

- Speed control: Accurate speed measurement helps the motor operate at optimal efficiency.

- Direction tracking: Encoders indicate whether the shaft is rotating clockwise or counterclockwise.

- Counting and indexing: In assembly lines and packaging machines, encoders help count the number of products and identify specific indexing points.

By performing these roles, encoders improve the overall performance, safety, and energy efficiency of the system. Without encoders, automation systems would have difficulty maintaining the high levels of accuracy required in modern manufacturing processes.

What does the encoder follow?

To perform accurately, an encoder follows several important principles and reference parameters:

- Mechanical Movement: Encoders follow the movement, either rotational or linear, of the mechanical element to which they are attached. This movement becomes the basis for signal generation.

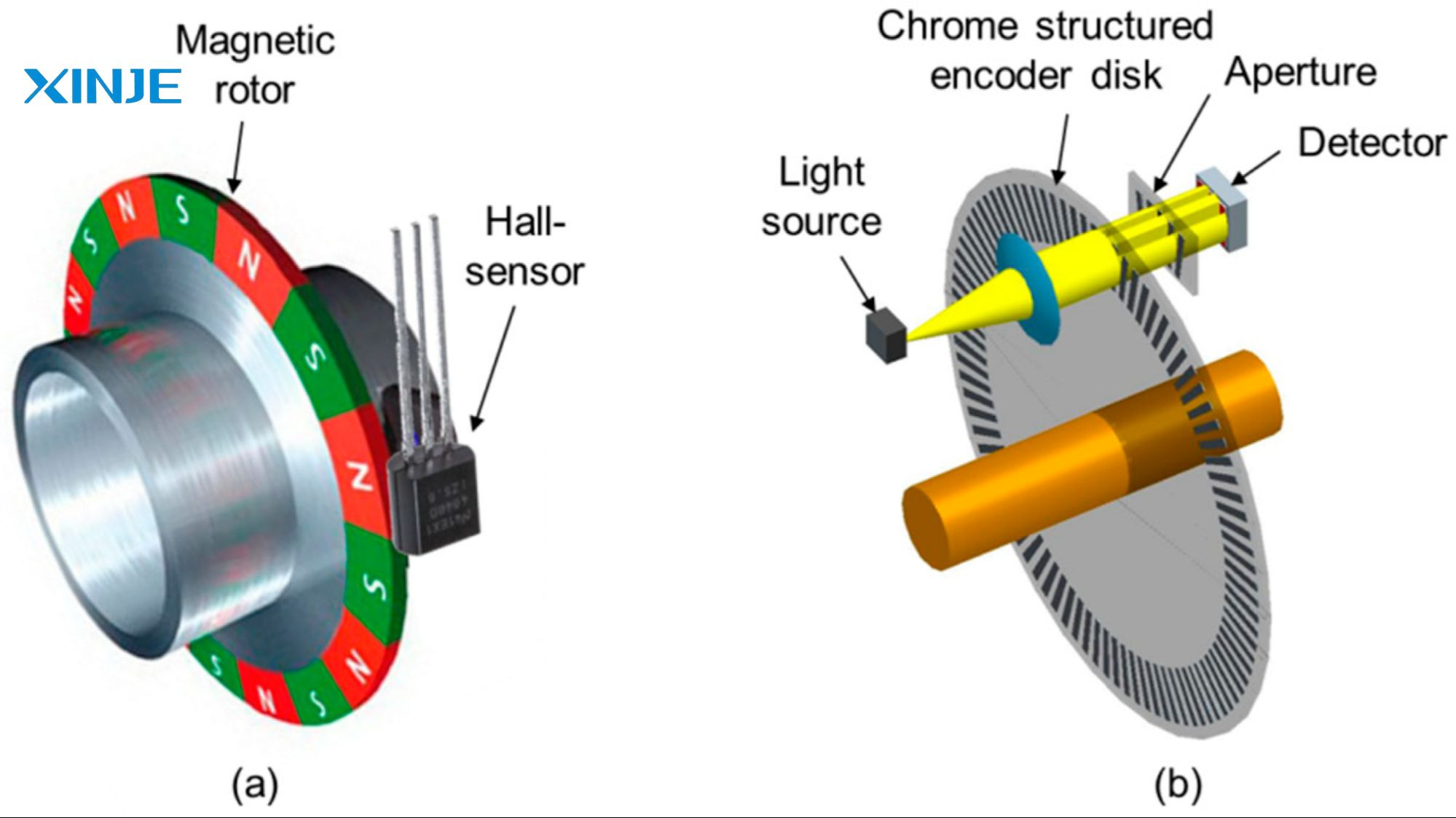

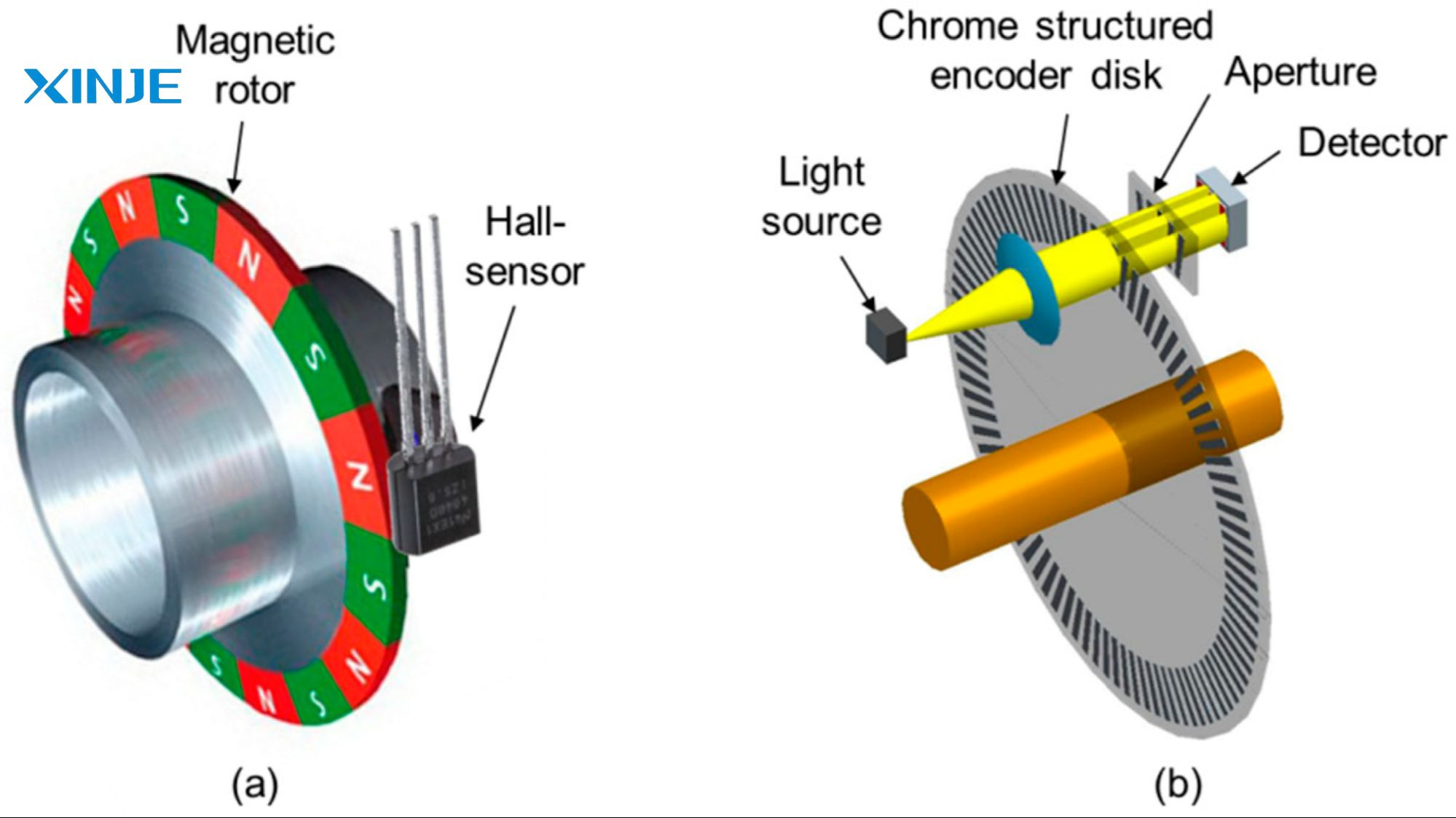

- Optical or Magnetic Detection: Encoders typically follow optical or magnetic encoding principles to sense position and movement. In optical encoders, a light source shines through a rotating disk with transparent and opaque lines. In magnetic encoders, the system tracks magnetic fields across poles.

- Pulses or Digital Signals: Most encoders follow a pattern of pulse generation. As the encoder disc or strip moves, it generates pulses or digital signals, which are interpreted by the control unit.

- Resolution and Accuracy: An encoder operates at a specific resolution, defined by the number of pulses per revolution (PPR) or counts per inch (CPI). The higher the resolution, the more precise the feedback.

What is the type of encoder?

Encoders come in various types, depending on their function, output signal, and application. Here are the most common types used in automation systems:

- Rotary encoder: A rotary encoder detects the rotational position and movement of a shaft. It is mounted directly on the motor or rotating part. Rotary encoders are divided into incremental rotary encoders to indicate relative motion. And absolute rotary encoders to provide a unique code for each shaft position.

- Linear encoder: Unlike rotary encoders, linear encoders measure linear displacement. They are used in systems that need to track linear motion, such as CNC machines or precision measuring instruments.

- Optical encoders: Optical encoders use light-emitting diodes, photodetectors, and encoder disks. They provide high resolution and accuracy, but can be sensitive to dust or vibration.

- Magnetic Encoders: Magnetic encoders detect changes in the magnetic field on rotating or moving magnetized materials. They are rugged, resistant to harsh environments, and suitable for industrial and outdoor use.

- Capacitive Encoders: Capacitive encoders use changes in capacitance to measure motion. They are a compact, low-cost alternative for applications that do not require extreme accuracy.

How do encoders work?

Understanding how an encoder works helps to appreciate its importance in automation systems. Although the internal mechanism may vary depending on the type, all encoders follow a similar process:

- Motion sensing: The encoder is attached to a rotating shaft or moving part. As the shaft rotates or moves, it drives a code disk or code strip containing a pattern.

- Generating a signal: Depending on the type, the encoder detects motion using an Optical Sensor, a Magnetic Sensor, or a Capacitive Sensor

- Pulse interpretation: These pulses are sent to a control device such as a PLC, servo controller, or motion controller. The controller interprets them to determine position, speed of movement, and direction of rotation

- Feedback to the Control Loop: Encoder feedback is used in a closed-loop control system to adjust the motor input, ensuring the system remains accurate, stable, and efficient.

Conclusion

Encoders are indispensable components in modern automation systems, delivering critical data about movement, position, speed, and direction. Whether you’re working with servo motors, robotics, CNC machinery, or conveyor systems, encoders enable precise and real-time control that boosts productivity and system reliability.

Understanding what an encoder is, how it works, and what types are available helps automation engineers, system integrators, and manufacturers choose the right encoder for their application. As automation technology continues to evolve, encoders will remain at the forefront, providing the feedback systems need to move forward with precision and purpose.