In the era of smart factories, processing data right at the device instead of depending on the central system is becoming an inevitable trend. Edge Computing, when integrated into HMI (Human-Machine Interface), not only helps increase response speed but also improves performance, security and flexibility in control. The following article by XINJE will help you understand the role, benefits and how to apply Edge Computing in modern industrial HMI systems.

What is Edge Computing?

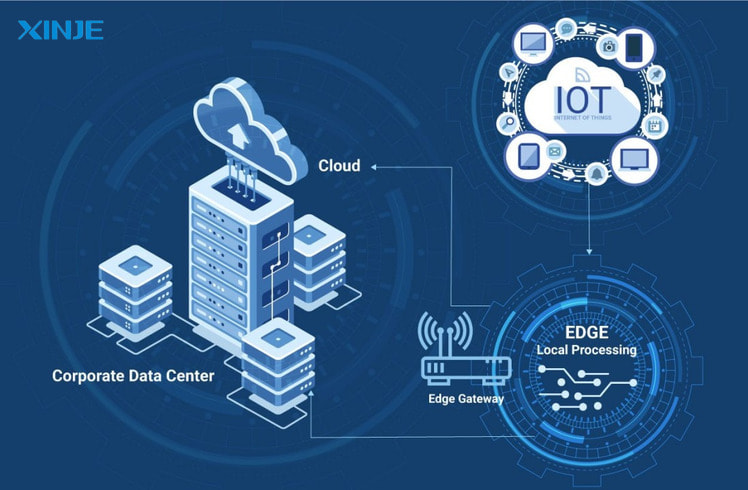

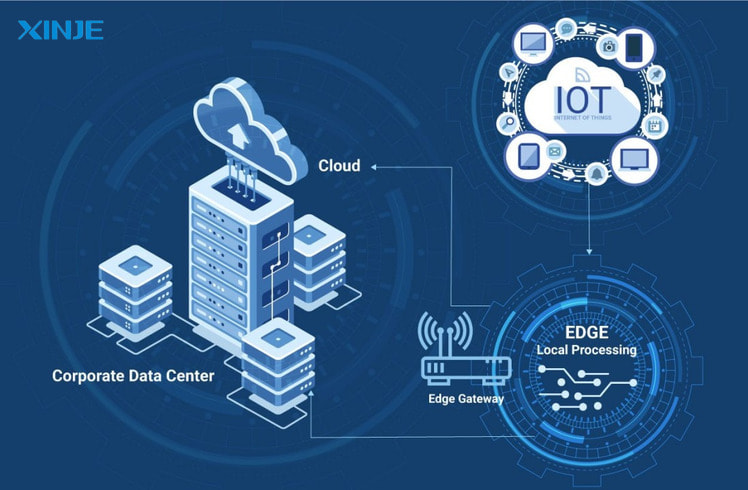

Edge Computing is a model of processing data right at the source device or near the source of the data, instead of sending all the information to a central server or cloud for processing. In the context of smart factories, this helps reduce latency, increase performance and ensure that data is processed promptly on-site.

When integrating Edge Computing into HMI, users can not only interact with the interface but also:

- Analyze sensor data in real time right on the HMI

- Display instant alerts when there is a deviation

- Send important data to SCADA or Cloud on demand, instead of all the information

This helps the HMI change from a traditional communication device to part of the intelligent processing system at the edge, supporting more effective production management.

What is the relationship between Edge Computing and HMI?

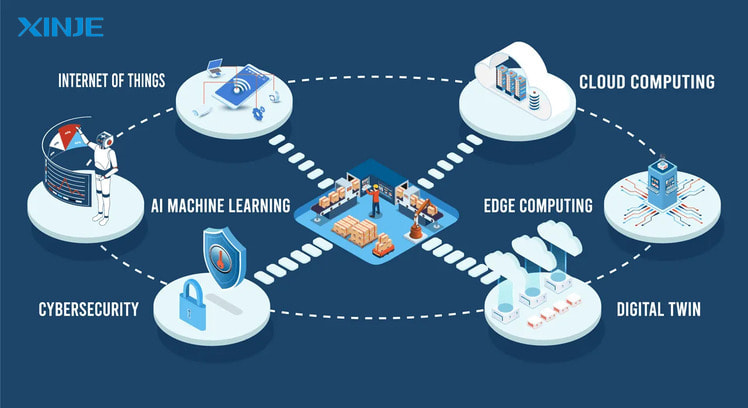

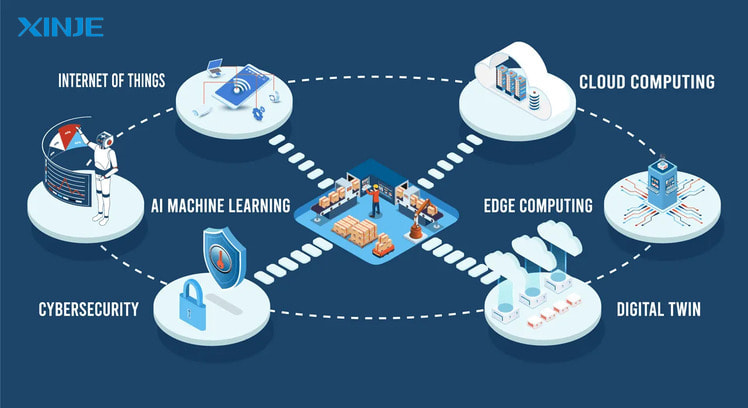

In modern automation systems, HMI (Human-Machine Interface) is no longer just an interface for displaying basic information or control, but is gradually becoming an important data processing node – thanks to the integration of Edge Computing.

- Data processing right at the HMI device: Edge Computing allows HMI to analyze and process sensor data, signals from PLC directly at the edge without having to send them to the control center. Thanks to that, HMI can issue warnings, control actions or display in real time.

- Converting from traditional HMI to intelligent HMI: If traditional HMI mainly plays a simple display and control role, HMI with integrated Edge Computing can take on advanced functions such as data analysis, information filtering, and local decision making.

- Increased flexibility in communication and connection: Edge HMI has better interoperability with other systems such as SCADA, MES or cloud, but only sends necessary data. As a result, businesses save bandwidth and improve system security.

The combination of Edge Computing and HMI is opening a new direction for smart factories – where all decisions, warnings and controls can be processed on-site, faster and more accurately than ever before.

What are the advantages of Edge Computing in industrial HMI systems?

The application of Edge Computing in HMI is not only technological but also creates clear advantages in factory management and operation.

- Real-time feedback: Edge HMI helps detect errors and issue warnings as soon as problems occur, instead of relying on the central control system. This helps minimize damage and downtime.

- Enhanced data security: Data is processed on-site, reducing the risk of leakage during transmission to the outside, especially when using the cloud.

- Reduce network load: Only necessary data is sent, while the majority of data is processed and stored at the HMI. This saves bandwidth and reduces pressure on the SCADA system or server.

- Support predictive maintenance and analysis: Edge HMI can collect and analyze equipment data in real time, thereby detecting signs of wear or anomalies – helping to plan maintenance more accurately.

- Improve operational efficiency: Reducing response latency and optimizing data flow helps the entire system run more smoothly, thereby increasing overall production efficiency.

What are the challenges of implementing Edge Computing in HMI?

Although Edge Computing brings many outstanding benefits when integrated into HMI, the implementation of this technology still faces some challenges that businesses need to pay attention to:

- High initial investment cost: Compared to traditional HMI, HMI devices that support Edge Computing often require more powerful hardware configurations such as high-performance CPUs, large memory and on-site storage capabilities. This can increase the initial investment cost.

- High technical requirements: Configuring, programming and maintaining Edge-integrated HMIs requires a team of engineers with knowledge of both HMI, industrial networking and edge computing technology.

- Compatibility with existing systems: Many factories are still using legacy systems that do not support fast communication or are not compatible with new Edge devices. Upgrading the entire system to synchronize can be costly and time-consuming.

- Difficulty in maintenance and updates: HMIs that operate independently in the field will require a separate software management and maintenance strategy. If not updated in time, Edge devices can become a security or performance weakness.

Although there are certain challenges, investing in the right direction and choosing the right HMI solution – such as XINJE’s industrial product lines – can help businesses overcome this barrier and quickly catch up with the trend of intelligent automation.

What should businesses consider when choosing HMIs with Edge Computing?

To maximize the benefits of Edge Computing, choosing the right HMI device is a key factor. Businesses need to consider the following criteria before investing:

- Hardware performance: Prioritize HMI devices with powerful processors, large RAM and enough storage to process data on site. This ensures that the analysis, display and response process is fast and uninterrupted.

- Ability to communicate with industrial equipment: HMI should support many communication protocols such as Modbus, CANopen, Ethernet/IP, Profibus, etc. to easily connect with PLCs, inverters and sensors in the factory.

- Scalability and flexibility: The device needs to be able to upgrade software, add local processing functions or integrate with other platforms such as SCADA, MES or cloud computing in the future.

- Technical support and reputable brand: Choosing to buy from an experienced supplier like XINJE helps businesses feel more secure about product quality, warranty policies as well as long-term technical services.

Conclusion

In the context of factories increasingly moving towards intelligent automation, integrating Edge Computing into HMI devices is not only a technological step forward but also a practical solution to help businesses improve performance, reduce latency and better control data in the field.

Although there are still some challenges in terms of cost, technology and integration capabilities, with the right choice of equipment – especially the Edge Computing integrated industrial HMI lines provided by XINJE – businesses can completely proactively seize opportunities, optimize operations and be ready for a comprehensive digital transformation journey.