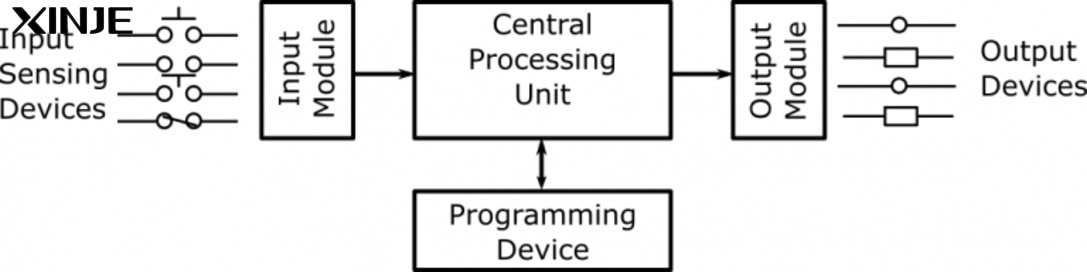

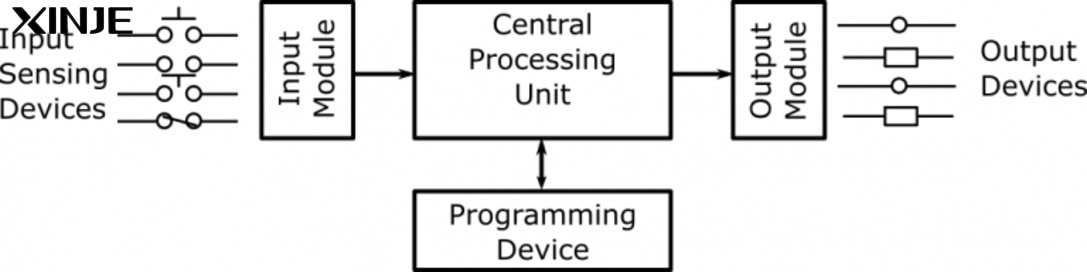

In the automation control system, the Programmable Logic Controller (PLC) acts as the “brain” that controls the entire process in the production line. However, for the PLC to interact with the user, it needs a bridge, which is the input/output interface. The I/O interface ensures that the PLC can collect information from sensors and control the actuator, creating an accurate and efficient work cycle.

What is an Input /Output Interface?

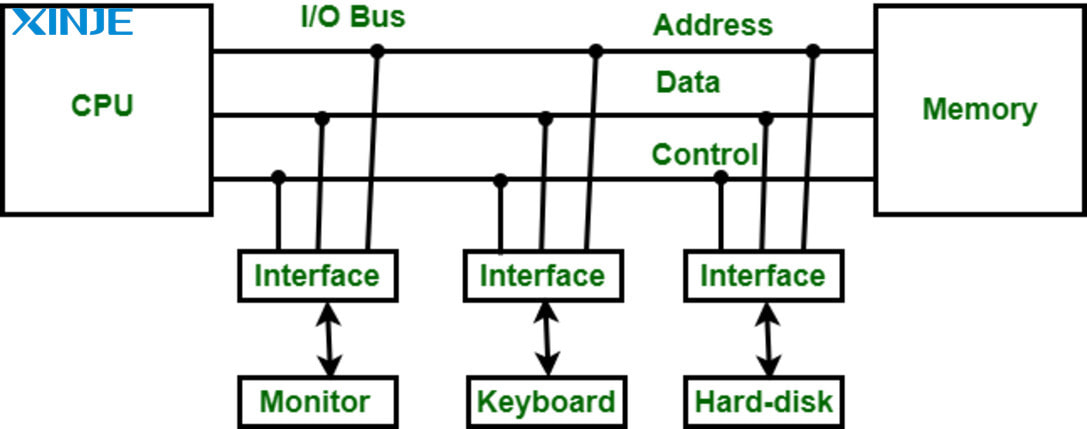

Input/Output Interface provides a method for transferring information between internal storage and external I/O devices. This is an indispensable component for PLC to receive signals from the environment (Input) and transmit control signals to devices (Output). Thanks to that, the entire operating process in the factory or production line is carried out automatically and accurately.

The operation process of Input/Output Interface usually takes place in 3 steps as follows:

- Input Interface: Collects data from peripheral devices and transmits that data to the CPU processor in the form of voltage or current signals. For example: switches, material detection sensors, temperature sensors, or travel switches.

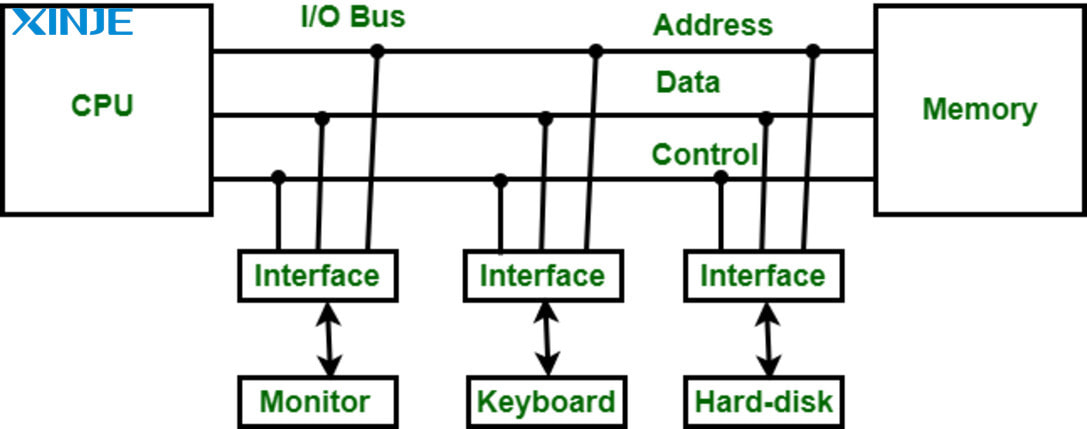

- Signal processing: The CPU will analyze the data, using programming languages in the PLC such as Ladder Logic, Structure text, … to make decisions.

- Output Interface: After the data is processed by the CPU, control signals will be sent to output devices such as relays, indicator lights, motors or control valves.

Why is the Input/Output Interface important?

In automation systems, Input/Output Interface (I/O Interface) plays an extremely important role because it is the bridge between the PLC controller and peripheral devices. Without I/O Interface, the PLC will not be able to receive data from sensors or switches, nor will it be able to send control signals to devices such as motors, relays or indicator lights. Therefore, I/O Interface helps the automation system operate smoothly, accurately, and efficiently. In this article, we will learn why I/O Interface is indispensable in the process of controlling and monitoring industrial applications.

- Helps automate the operating process: This helps minimize human errors, increase efficiency and maintain stability in operation.

- Reduce the processing load on the CPU: By pre-processing the input signal, Input/Output Interface helps reduce the direct workload on the PLC’s CPU. This increases the performance and efficiency of the system.

- Scalability: I/O Interface allows the PLC system to easily expand the number of inputs/outputs and integrate with new devices without changing the entire system structure.

- Ability to integrate with industrial networks: I/O Interface is often designed to integrate with industrial networks such as Profibus, Ethernet/IP, Modbus, making it easy to connect and exchange data with other systems in the factory. This ensures continuity and synchronization throughout the entire production process.

- Ensuring high accuracy and consistency: Signals are processed using high-level programming languages such as Ladder Logic, Structure text, Function Block Diagram (FBD) … to ensure accuracy and reliability during operation.

How many types of input/output interfaces are there?

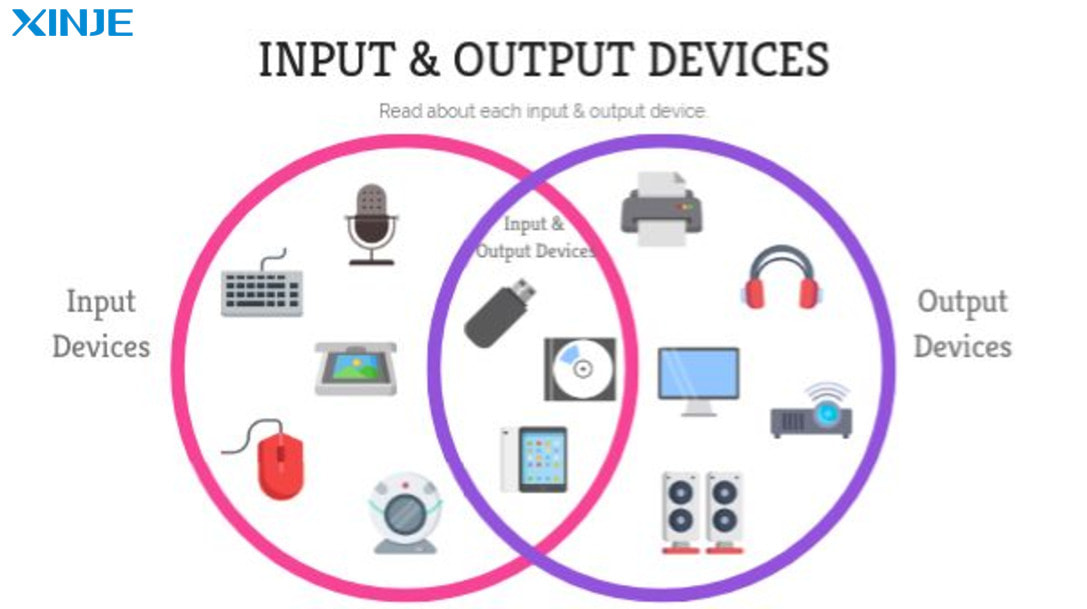

Classification by signal type

- Digital I/O: Receives binary signals (ON/OFF, 1/0). This is a simple signal with two states, often used in on/off applications.

- Analog I/O: Receives analog (continuous) signals from sensors such as temperature sensors, pressure sensors, current sensors. The signal is usually in the form of voltage (0-10V) or current (4-20mA).

Classification by connection method

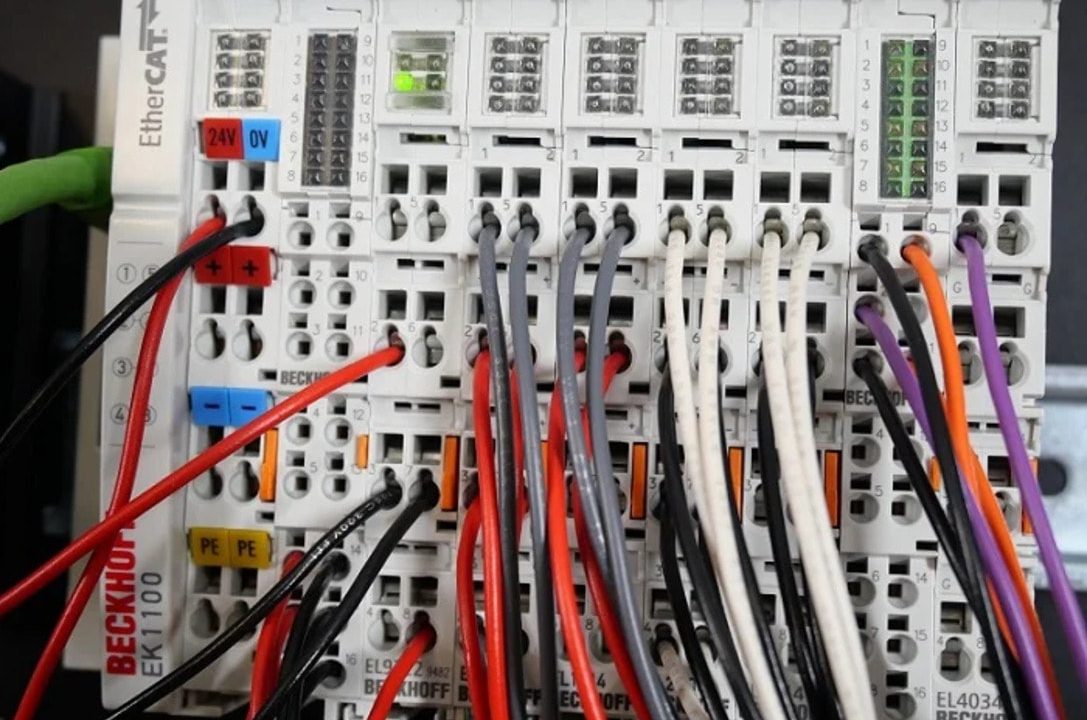

- Wired I/O: This is a traditional connection method through physical wires.

- Wireless I/O: Uses wireless protocols such as Zigbee, Wi-Fi, or Bluetooth to transmit signals.

Based on connection form

- Local I/O: I/O modules are directly connected to the PLC, often mounted in the same rack or frame.

- Remote I/O: I/O modules are located remotely and connected to the PLC via network protocols such as Ethernet/IP, Profibus, or Modbus. This allows for easy system expansion and reduces wiring costs.

Classification by number of channels

- Discrete I/O: Designed to connect individual input/output devices. Discrete I/O primarily handles binary signals with two states ON (1) or OFF (0).

- Modular I/O: Integrates multiple I/O channels into one module, saving space and making them easy to replace when needed. Modular I/O can handle both digital and analog signals, and is often designed for easy expansion.

Choosing the right I/O Interface type depends on the specific needs of the application and operating environment. By understanding the types of I/O Interfaces and their characteristics, you can optimize your PLC system for maximum efficiency and reliability.

Conclusion

Input/Output Interface is an important component in the PLC system, ensuring accurate communication between the controller and peripheral devices. The effective design and operation of this interface will help optimize the performance of the automation system, from the production line to the energy monitoring system.

In the era of Industry 4.0, the integration of IoT technology and artificial intelligence into the Input/Output Interface promises to bring great progress, contributing to significantly improving production efficiency and reducing operating costs.