How to Operate & How to Use Standard HMI Alarm Function

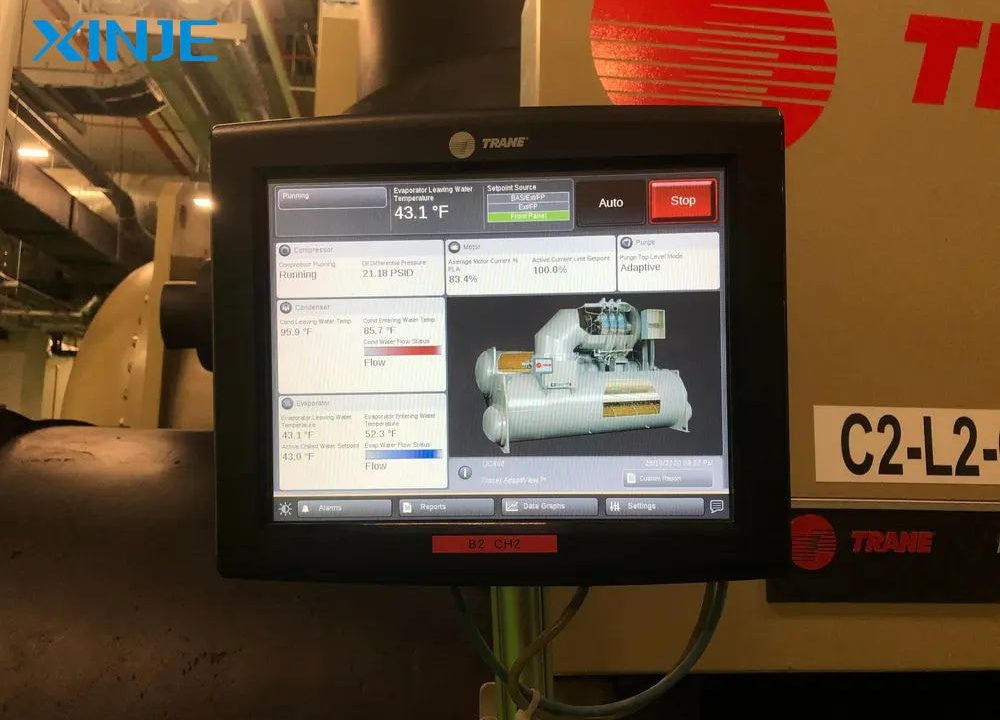

HMI Alarm Function is a feature that helps detect and promptly warn of problems in the automation system. Thanks to that, the operation line is safer, reduces downtime and optimizes monitoring. This article by XINJE will help you understand the principles, benefits and notes when installing Alarm on HMI. What is HMI Alarm Function? Alarm […]