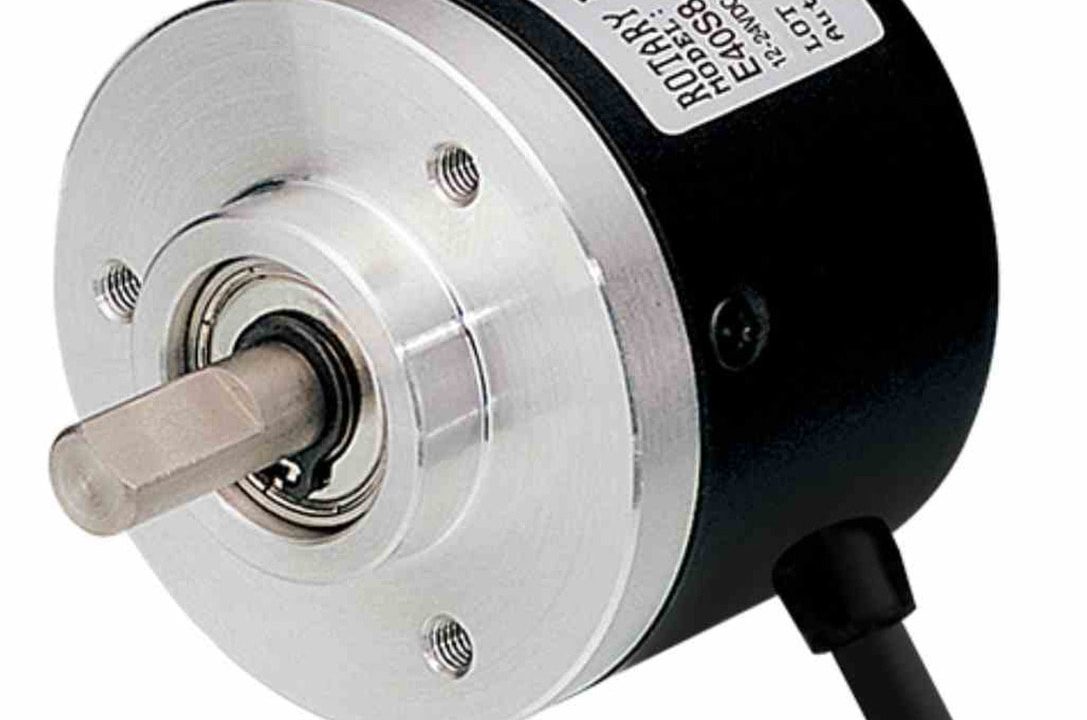

Rotary encoders are electromechanical devices that are placed inside specialized motors to determine the exact positions and velocities of objects. These devices are widely used in the automation industry such as assembly lines and labeling…

Rotary encoders have different classifications, with outstanding features, can rotate continuously at a free angle of 360 degrees, and observe objects accurately. It can be said that rotary encoders are affordable but highly applicable devices, any production facility should own them.

What is the use of the rotary encoder?

Rotary encoders are commonly used for monitoring and control. They are widely used in many industrial automation fields for direction transmission and speed control. In addition, this device is also used for motor feedback to control the speed of the transmission shaft, popular in labeling machines, textile machines, etc.

How many main classifications are there of rotary encoders?

There are many types of rotary encoders, but they can be divided into three main categories: incremental, absolute and linear encoders.

- Incremental encoders: are devices that work by converting the rotational motion of a shaft into a series of electrical pulses to determine the direction and angle of rotation. This classification can operate based on optical, magnetic, or mechanical principles, with two output signals (A and B) offset from each other to determine the direction of rotation.

- Absolute encoder: This device helps to locate, adjust, and synchronize rotating parts in machinery, capable of providing precise position information of the shaft, regardless of the state of rotation or rest, they are important devices in controlling speed and position in automation systems

- Linear encoder: This type is commonly used to encode linear movements. Unlike the previous two types, linear encoders accurately measure and control the position, movement, and speed of an object moving along a straight axis, playing an important role in precisely controlling movements in many automation applications.

Why does the rotary encoder often fail during operation?

Like other products, rotary encoders can encounter some problems that affect the operating efficiency of the device such as:

- Bent shaft: The shaft of the rotary encoder should be straight for best operation. When the shaft is bent, it puts more pressure on the bearing, which can cause thermal overload.

- Influenced by the environment: when the device operates in places with dusty environments or temperatures that easily change suddenly… environmental factors can easily affect the operating efficiency, making it susceptible to damage.

- Signal problems: rotary encoders often encounter problems related to installation, interference, or short circuits leading to problems in the output signal of the device

How are rotary encoders and potentiometers different?

| Rotary encoders | Potentiometers |

| Continuous operation in both directions | Limited to rotate at a certain angle |

| More complex setup than the potentiometer | Easy setup |

| Consists of a rotating shaft, encoder disc, phototransistor, and signal processing circuit. | The structure consists of positive, and negative voltage and a slider connection that acts as a voltage divider. |

| High-precision control and digital system integration | Requires continuous control, and has relative precision |

| Use digital signal | Use analog signal |

| Around $20 – $70 | Around $20 |

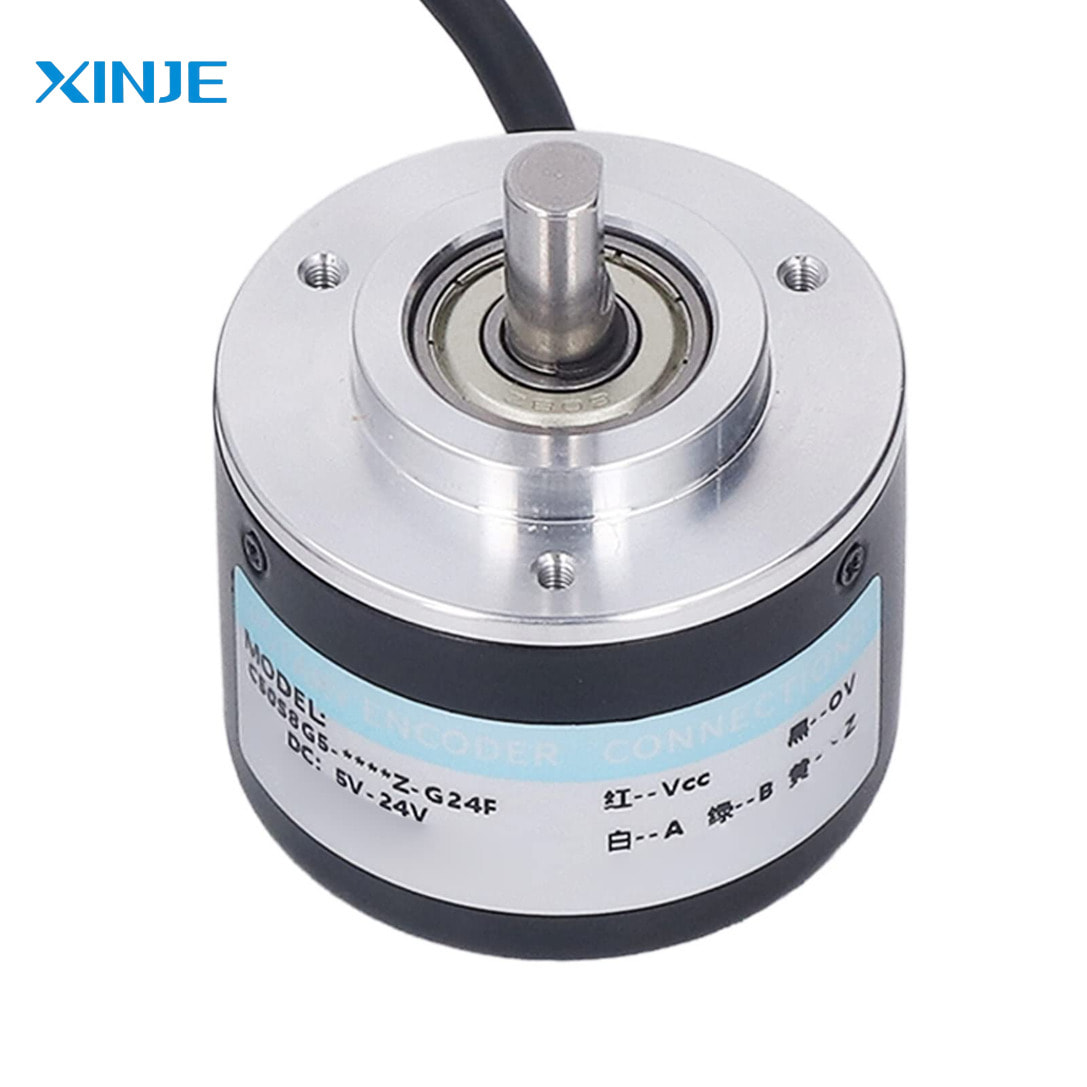

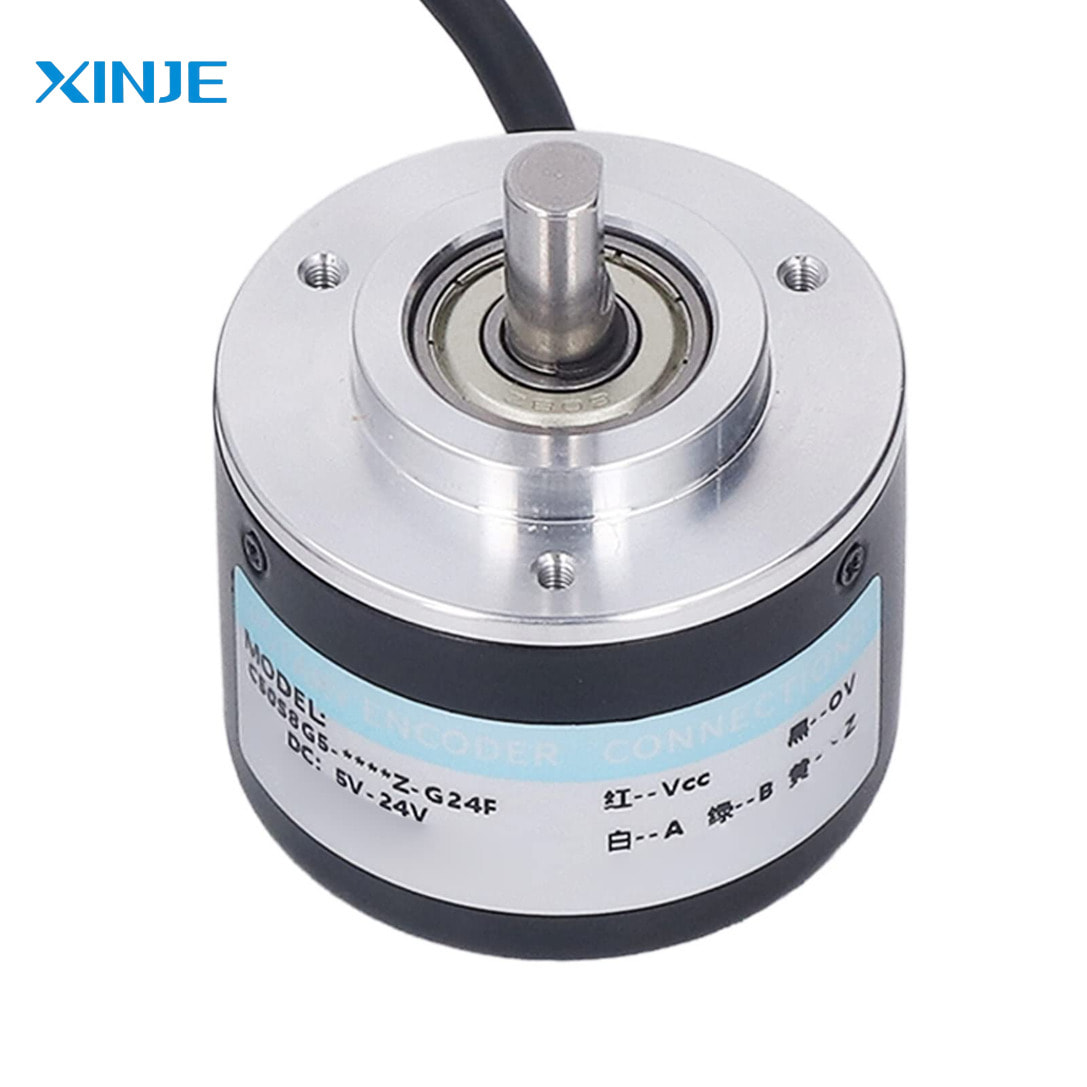

Where can you buy the rotary encoder?

Many units provide rotary encoders with various classifications and prices, making it difficult for users to choose genuine products and easy to buy poor-quality products. So why don’t you choose Xinje to have absolute peace of mind when buying rotary encoders?

We commit:

- 100% genuine products with clear origin documents.

- Comprehensive 12-month warranty and support for fast delivery within the day.

- Free installation and transportation services within the allowed range.

- A team of professional staff is ready to advise, analyze your needs, and provide the most suitable solution for your budget.

Please contact us immediately via the hotline below for support and answers to all questions. Xinje is always ready to serve you!