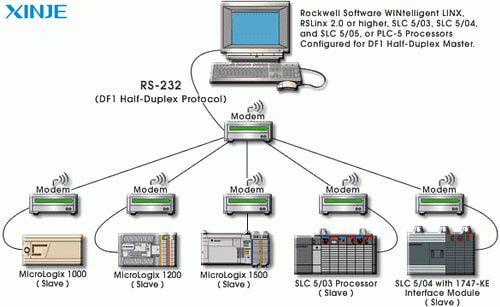

The DF-1 protocol is a proprietary communication protocol developed by Allen-Bradley, a brand under Rockwell Automation. It is widely used for data exchange between industrial automation devices such as programmable logic controllers (PLCs), human-machine interfaces (HMIs), and personal computers. The DF-1 protocol facilitates reliable communication in industrial environments when operating on a full-duplex or half-duplex basis.

In essence, DF-1 acts as the “language” enabling various devices within an automated system to understand each other. This protocol is instrumental in streamlining operations, monitoring systems, and maintaining industrial processes across diverse sectors.

Why is the DF-1 Protocol important in automation?

In the field of industrial automation, seamless communication between devices is crucial. Here are some reasons why the DF-1 protocol is so important:

- Reliability in data transmission: DF-1 ensures accurate data exchange between devices, minimizing errors and maintaining consistency in operations. Its robust design enables it to operate reliably, even in harsh industrial environments.

- Flexibility across devices: The DF-1 protocol is compatible with a wide range of devices, including Allen-Bradley PLCs, HMIs, and industrial computers. This flexibility simplifies system integration and reduces compatibility issues.

- Ease of implementation: The protocol’s simple design makes it easy for engineers to deploy and configure. This simplicity saves time and reduces the complexity of system development.

- Cost-effective: By using the DF-1, industries can extend the life of existing automation systems without needing costly upgrades. This cost-effective approach is especially suitable for businesses with limited budgets in the early stages.

How does the DF-1 protocol work?

The DF-1 protocol operates using a straightforward command-response structure, enabling efficient communication. Below is an overview of its working mechanism:

Message Frame

DF-1 uses specific message frames to ensure data integrity. Each frame includes a start delimiter, data payload, and error-checking fields. This structure ensures accurate message delivery.

Communication Modes

- Full-Duplex Mode: Allows simultaneous two-way communication, increasing efficiency.

- Half-Duplex Mode: Supports one-way communication at a time, often used in systems where full-duplex isn’t required.

Error Checking and Acknowledgment

The protocol employs cyclic redundancy checks (CRC) or longitudinal redundancy checks (LRC) to detect errors. If a message is received successfully, an acknowledgment is returned to the sender, ensuring reliable data exchange.

Polling and Token Passing

DF-1 can use polling or token-passing mechanisms to manage communication in multi-device setups. Polling involves a master device requesting data from slaves, while token passing allows devices to take turns transmitting data.

Where is the DF-1 Protocol commonly used?

The DF-1 protocol finds applications in various industries and automation scenarios. Below are some of its most common use cases:

- Manufacturing Plants: DF-1 facilitates communication between PLCs and supervisory systems in factories, ensuring smooth production processes and timely fault detection.

- Oil and Gas Industry: DF-1 is used for remote monitoring and controlling equipment in oil rigs and pipelines, ensuring operational safety and efficiency.

- Water and Wastewater Treatment: Automation systems in this sector rely on DF-1 to monitor flow rates, pressure levels, and other critical parameters.

- Transportation Systems: DF-1 supports the operation of automated conveyor belts, traffic management systems, and other transportation-related automation.

- Energy Sector: regeneration and distribution systems use DF-1 for real-time data collection and system diagnostics, optimizing performance and reducing downtime.

What are the limitations of the DF-1 protocol?

Although the DF-1 protocol has great benefits, it still has certain limitations that users need to be aware of during use:

- Limited speed: Compared to modern communication protocols such as EtherNet/IP, DF-1 operates at a slower data transmission rate. This can be a drawback in systems that require high-speed communication.

- Proprietary nature: As a proprietary protocol, DF-1 is mainly limited to Allen-Bradley and Rockwell Automation devices, limiting interoperability with third-party systems.

- Scalability issues: DF-1 is less suitable for large-scale automation systems with many devices, as it may have difficulty handling increased data volumes efficiently.

- Absolution risk: With the advent of newer, more advanced protocols, DF-1 is gradually becoming obsolete. Companies that rely solely on DF-1 may face challenges integrating modern technologies.

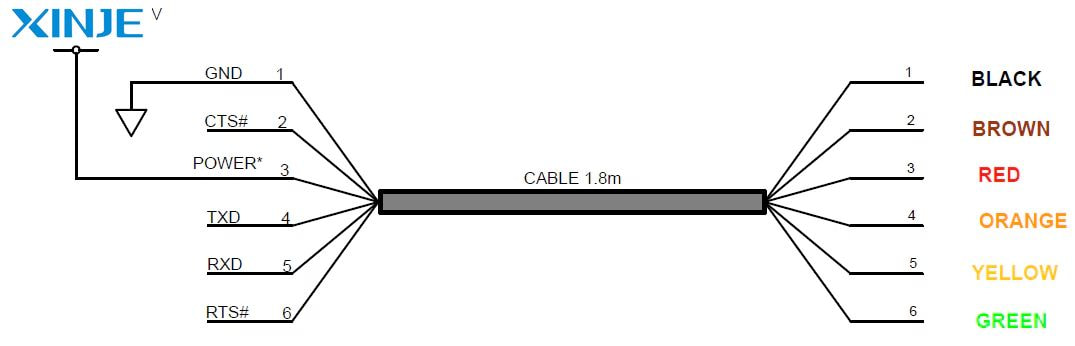

- Complex wiring requirements: Traditional DF-1 systems often require extensive wiring, which can increase installation costs and complicate maintenance.

Conclusion

The DF-1 protocol remains a cornerstone in industrial automation, offering reliable and straightforward communication between devices. Its versatility and ease of use make it a preferred choice in many sectors, including manufacturing, energy, and water treatment. However, as automation technology evolves, industries must weigh its benefits against its limitations, particularly in terms of speed and scalability.

For businesses in Automation, understanding the DF-1 protocol’s strengths and weaknesses can aid in making informed decisions about adopting or upgrading automation systems. While DF-1 may not be the most advanced protocol available, its proven track record ensures it will continue to play a vital role in industrial automation for years to come.