DeviceNet is a robust industrial communication protocol widely used in automation systems to facilitate efficient data exchange between controllers and field devices. Originally developed by Rockwell Automation, it is based on the CAN (Controller Area Network) protocol. DeviceNet provides a cost-effective and reliable solution for real-time communication in industrial environments, making it an essential component in Malaysia’s fast-growing automation sector.

DeviceNet is particularly valued for its ability to connect multiple devices such as sensors, actuators, and controllers in a single network. By simplifying wiring and enhancing interoperability, DeviceNet ensures seamless communication in complex automation systems, contributing to improved productivity and reduced operational costs.

What are the outstanding features of DeviceNet?

DeviceNet offers several features that set it apart from other industrial communication protocols. Here are some of its key advantages:

- Simplified Wiring: DeviceNet uses a single cable for both power and data, reducing the need for complex wiring systems. This not only minimizes installation costs but also simplifies maintenance and troubleshooting.

- High Interoperability: As an open standard protocol, DeviceNet supports devices from multiple vendors. This ensures compatibility and flexibility in designing automation systems, making it a popular choice for industries in Malaysia.

- Real-Time Communication: DeviceNet’s use of the CAN protocol enables fast and reliable data transfer, which is critical for time-sensitive industrial processes.

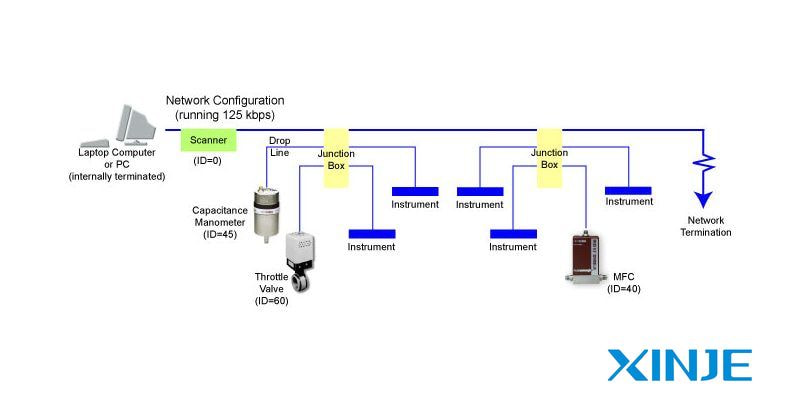

- Scalability: DeviceNet networks can accommodate up to 64 nodes, making it suitable for both small and large-scale automation systems.

- Integrated Diagnostics: DeviceNet provides built-in diagnostic features that allow users to monitor network performance and identify issues quickly, reducing downtime and enhancing system reliability.

How does DeviceNet work?

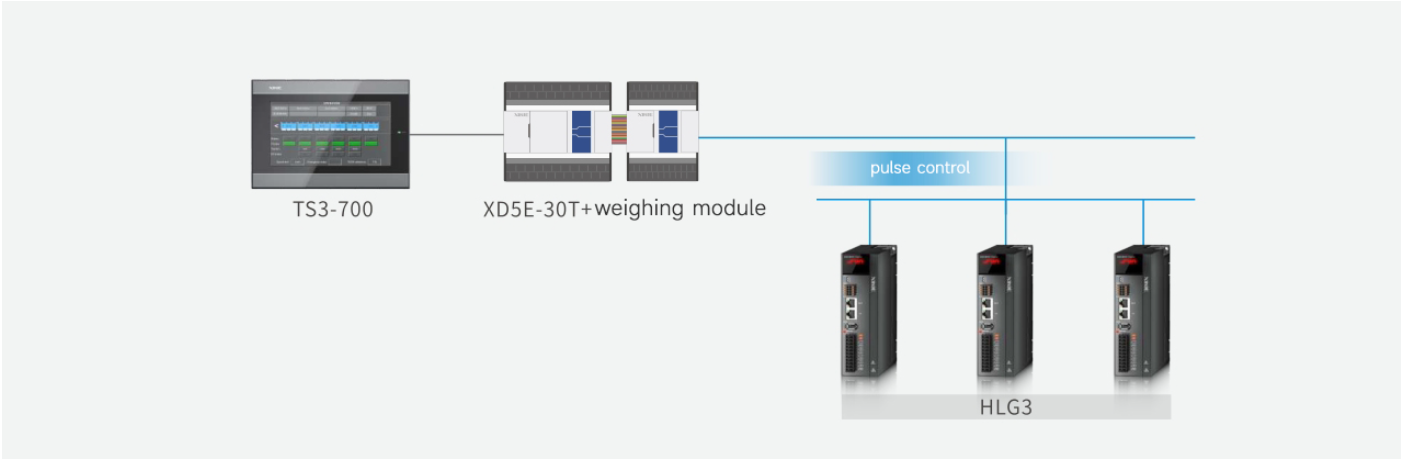

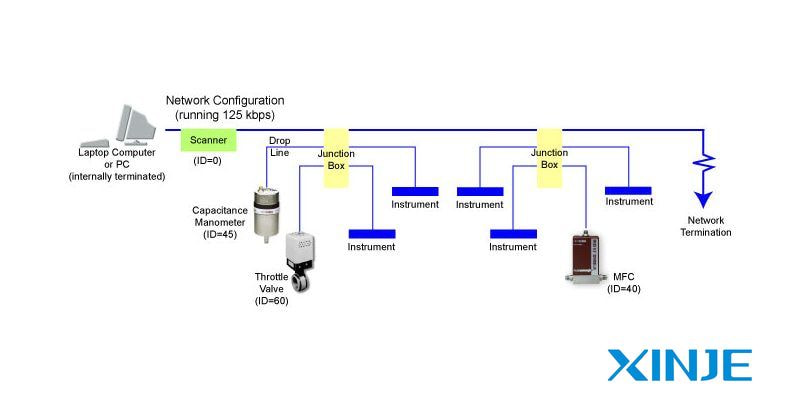

DeviceNet operates on a master-slave architecture where a master device, such as a programmable logic controller (PLC), communicates with multiple slave devices, including sensors and actuators. Here’s how it works:

- Communication Protocol: DeviceNet leverages the CAN protocol for data exchange. Each device on the network is assigned a unique address, allowing for efficient communication and coordination.

- Data Exchange: Data is transmitted in the form of messages, with priority levels assigned to ensure critical information is processed first.

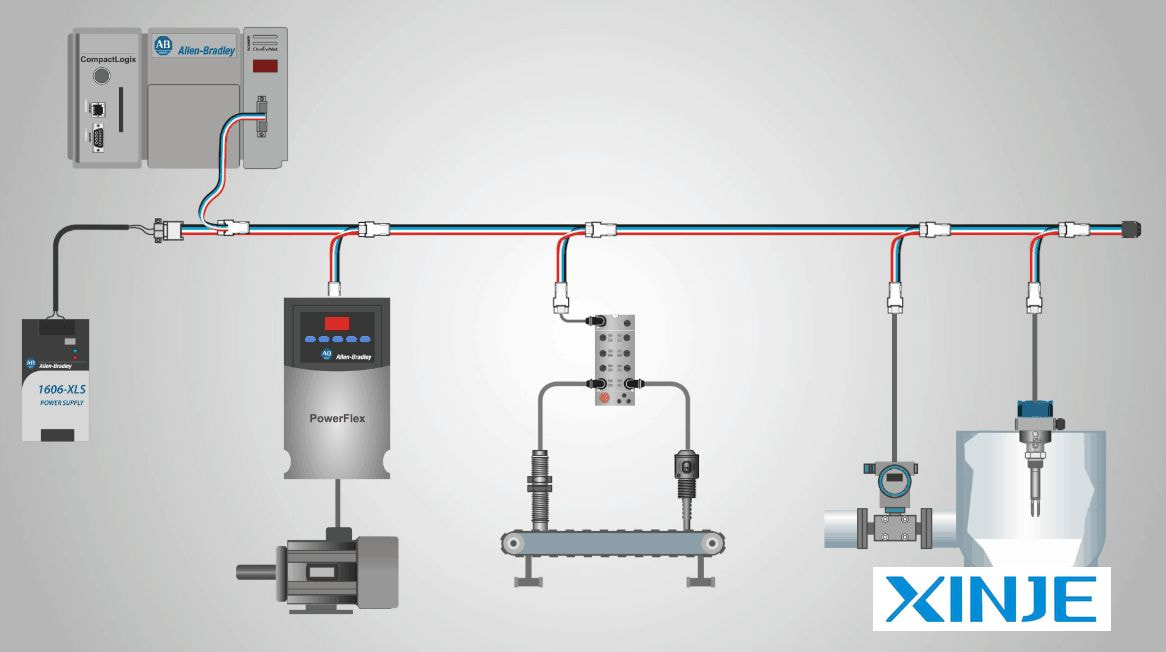

- Power and Data Integration: DeviceNet cables integrate both power supply and data signals, enabling devices to operate with minimal wiring complexity.

- Error Handling: The protocol includes error detection and correction mechanisms, ensuring data integrity and network reliability.

Is DeviceNet the same as Ethernet?

While DeviceNet and Ethernet are both widely used in industrial automation, they differ in several key aspects:

- Protocol Basis: DeviceNet is based on the CAN protocol, whereas Ethernet uses the TCP/IP protocol.

- Applications: DeviceNet is primarily designed for real-time communication in field-level devices, while Ethernet is more commonly used for higher-level network communication, such as linking enterprise systems.

- Network Speed: Ethernet offers higher data transfer rates compared to DeviceNet, but DeviceNet’s speed is sufficient for most field-level applications.

- Wiring: DeviceNet integrates power and data in a single cable, whereas Ethernet typically requires separate power sources for connected devices.

In summary, DeviceNet and Ethernet serve different purposes in automation systems and are often used together to achieve optimal performance.

What are typical applications of DeviceNet?

DeviceNet is widely used in various industrial applications in Malaysia, thanks to its versatility and reliability. Common use cases include:

- Manufacturing: DeviceNet is extensively used in automotive and electronics manufacturing to control assembly lines and robotic systems.

- Process Automation: Industries such as oil and gas, chemical processing, and food production rely on DeviceNet for real-time monitoring and control of processes.

- Material Handling: Conveyor systems and automated guided vehicles (AGVs) use DeviceNet for efficient coordination and operation.

- Building Automation: DeviceNet is employed in HVAC systems, lighting controls, and security systems to ensure seamless integration and operation.

Conclusion

DeviceNet remains the cornerstone of industrial automation in Malaysia, offering unparalleled reliability, scalability, and simplicity. From manufacturing plants to process automation, the ability to streamline communication between devices has revolutionized the way industries operate.

Whether you are looking to optimize existing systems or implement new automation solutions, understanding the features and applications of DeviceNet can help you make informed decisions. As the automation industry continues to evolve, leveraging powerful protocols like DeviceNet will be key to staying competitive in the market.