In today’s rapidly advancing automation landscape, seamless communication between devices is critical for efficient and reliable operations. The Device Description Language (DDL) plays a pivotal role in achieving this by providing a standardized method for describing the functionality and parameters of industrial devices. DDL enables engineers and system integrators to understand, configure, and integrate devices from different manufacturers into a unified system without compatibility issues.

DDL bridges hardware and software, ensuring that devices can interact seamlessly within an Industrial Internet of Things (IIoT) ecosystem. As Malaysia’s industrial sectors embrace smart manufacturing and Industry 4.0 principles, the importance of DDL becomes even more apparent.

How does Device Description Language (DDL) work?

DDL is a textual representation of a device’s characteristics and capabilities. It provides a detailed description of the device’s parameters, communication protocols, and behavior. Using DDL, device properties are encoded in a way that can be interpreted by control systems, Human Machine Interfaces (HMIs), and engineering tools.

Here’s how DDL works:

- Standardized structure: DDL uses predefined syntax and structure to describe device parameters, such as input/output signals, configuration options, and diagnostic data.

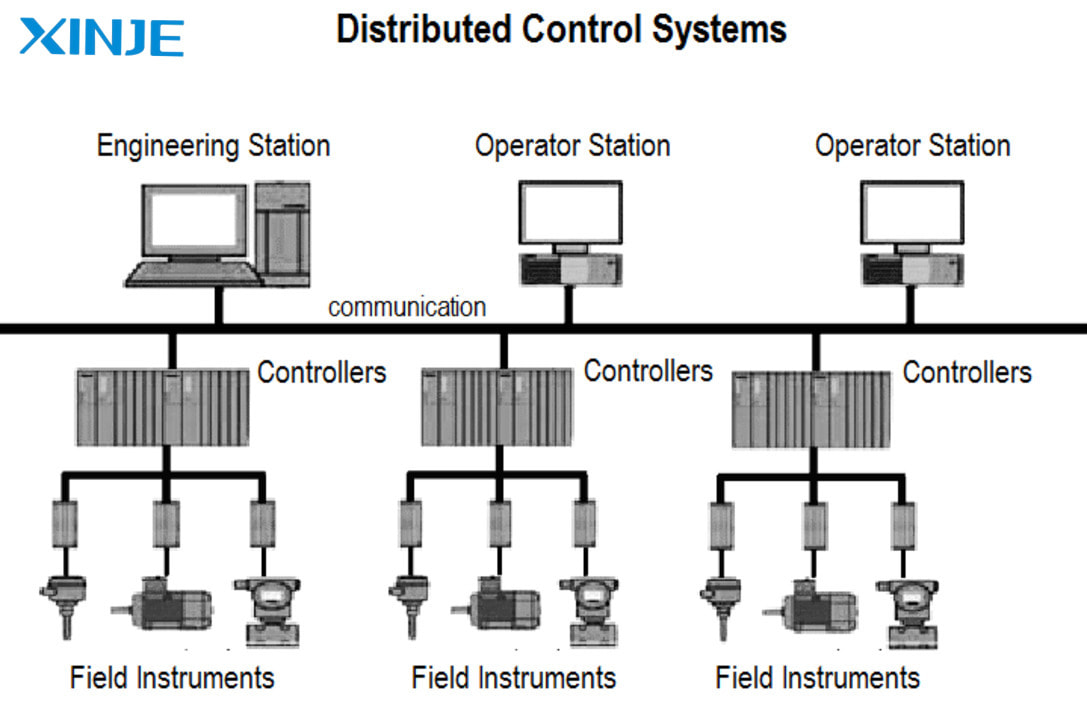

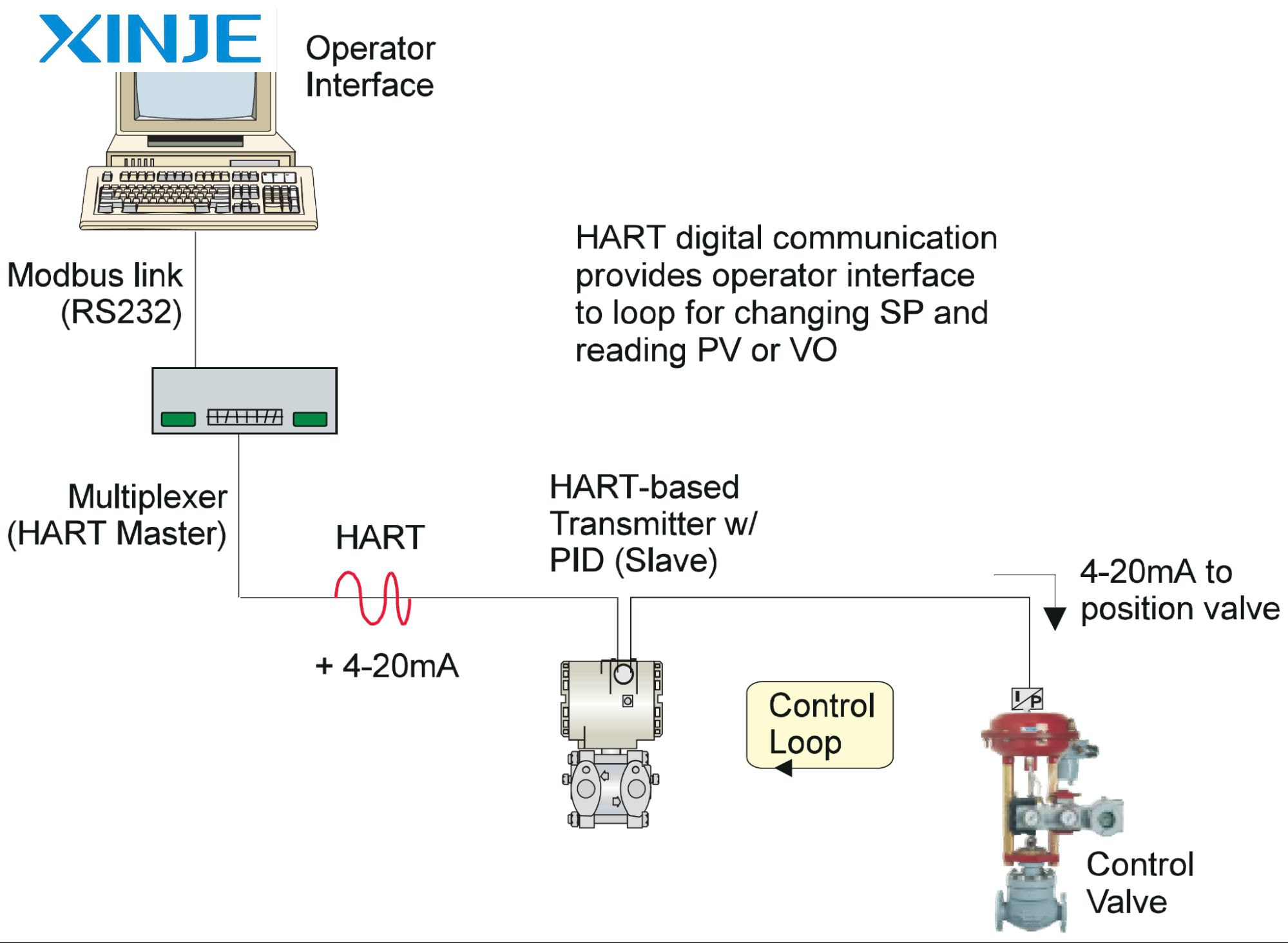

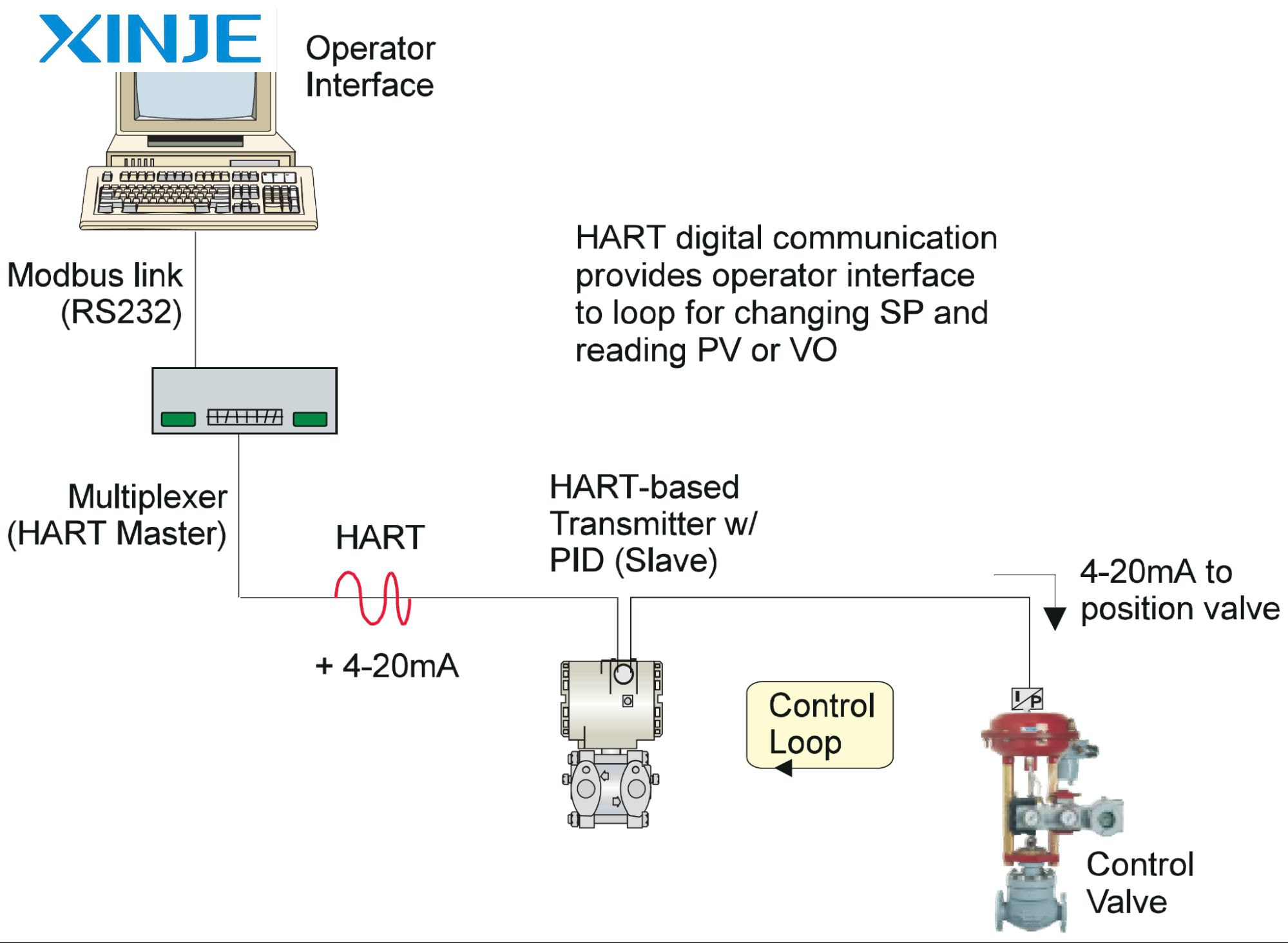

- Integration with communication protocols: It supports a variety of industrial communication protocols, such as HART, PROFIBUS, and FOUNDATION Fieldbus, allowing devices to communicate efficiently within an automation system.

- Tool-readable: Engineering tools and asset management systems interpret DDL files to visualize and configure devices. For example, a DDL file can help an engineer understand the operating status of a sensor or adjust the sensor’s settings.

Where is Device Description Language applied?

DDL is widely used across various industries to streamline device integration and management. Some key applications include:

- Process Automation: In industries such as oil and gas, chemical processing, and pharmaceuticals, DDL enables precise control and monitoring of field devices, such as valves, sensors, and actuators.

- Factory Automation: Manufacturing lines rely on DDL to ensure that all devices, from robots to conveyors, work in harmony.

- Energy Sector: Power plants and renewable energy facilities use DDL to manage and monitor complex equipment.

- Smart Cities: DDL supports the integration of IoT devices in urban infrastructure, including traffic management systems and smart grids.

What are the outstanding features of Device Description Language?

DDL stands out due to its robust features that make it indispensable for automation systems:

- Interoperability: By providing a standardized framework, DDL ensures that devices from different manufacturers can communicate effectively.

- Scalability: DDL is suitable for small-scale applications as well as large, complex systems, making it versatile across various industries.

- Diagnostic Capabilities: DDL provides detailed diagnostic information, helping engineers quickly identify and resolve issues, and reducing downtime.

- User-Friendly Configuration: With DDL, users can easily configure devices through intuitive interfaces supported by engineering tools.

- Future-Ready: DDL is designed to adapt to emerging technologies and protocols, ensuring its relevance in the evolving automation landscape.

How to set Device Description Language?

Setting up the Device Description Language (DDL) requires a highly specialized technician to understand each step. Basically, the installation will include the following steps:

- Obtaining the DDL File: Manufacturers typically provide DDL files for their devices. These files are typically available for download from their websites or included with the device.

- Install Compatible Tools: Use engineering tools or asset management software that supports DDL. Examples include AMS Device Manager, PACTware, or vendor-specific tools.

- Loading the DDL File: Importing the DDL file into the software to enable device identification and configuration.

- Connecting the Device: Ensuring that the devices are physically connected to the system and communicating over supported protocols.

- Configuring and Testing: Using the software to configure device parameters, perform diagnostics, and test the setup to ensure everything is working as expected.

What to keep in mind when using Device Description Language?

While the Device Description Language (DDL) has always been a standout in terms of its many benefits in the Automation industry, there are still some considerations that users need to keep in mind to ensure effective use:

- Compatibility: Always verify that DDL files are compatible with your software and device tools. Outdated or incorrect files can lead to errors.

- Updates: Regularly update DDL files and engineering tools to take advantage of the latest features and ensure compatibility with new devices.

- Training: Ensure that your team is trained to work with DDL and related tools. This helps maximize the benefits of the technology.

- Data Security: Protect your systems from unauthorized access by implementing strong cybersecurity measures. This is especially important for industries in Malaysia that handle sensitive data.

- Local Regulations: When using DDL, consider any local standards or regulations, especially in areas such as energy and pharmaceuticals where compliance is critical.

Conclusion

The Device Description Language (DDL) is a cornerstone of modern automation systems, providing the foundation for seamless device integration and communication. Its ability to enhance interoperability, simplify configuration, and support diagnostic capabilities makes it a vital tool for automation industries aiming to achieve smart manufacturing and Industry 4.0 objectives.

As Automation continues to advance its automation capabilities, adopting and effectively using technologies like DDL will be key to maintaining competitiveness in the global market. By understanding how DDL works, where it can be applied, and the best practices for its implementation, businesses can unlock its full potential and drive innovation across their operations.