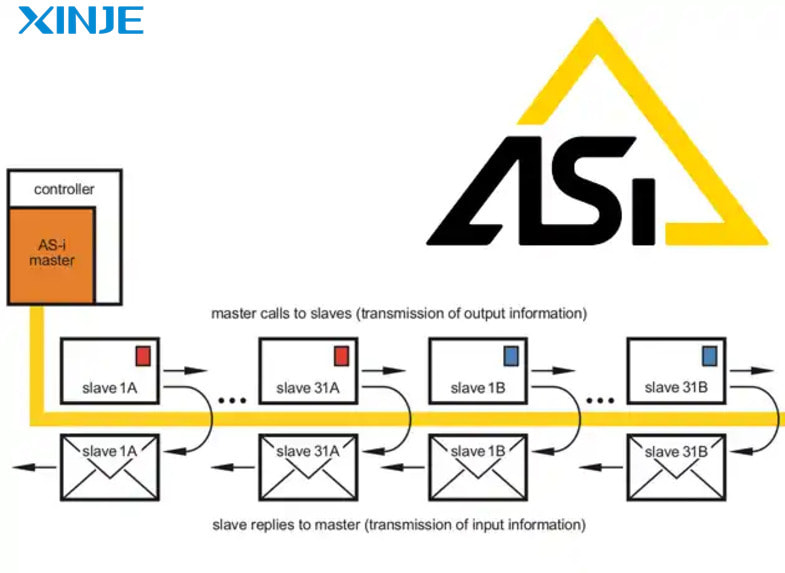

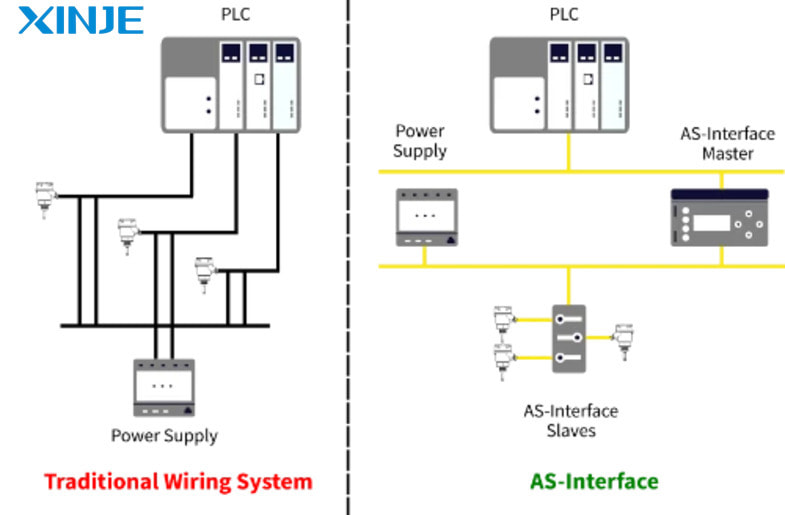

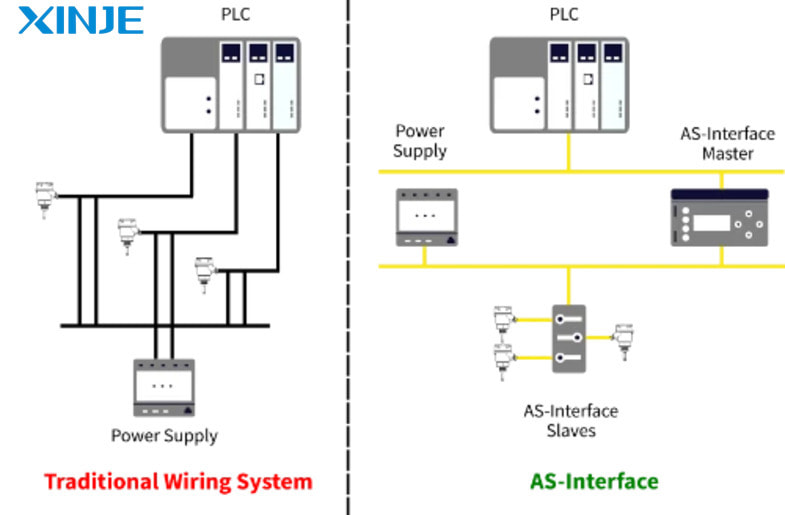

AS-Interface (Actuator Sensor Interface) is a simple, low-cost industrial communication standard widely used in factory and industrial automation systems. AS-Interface is specifically designed to connect sensors and actuators in production lines, replacing the traditional complex wiring method.

The AS-Interface protocol was developed by a consortium of European automation equipment manufacturers and it is designed to simplify the connection of input/output devices to automation systems.

What are the outstanding features of AS-Interface?

AS-Interface (Actuator Sensor Interface) is not only known as a simple industrial communication protocol, but also stands out thanks to its outstanding features that help optimize performance and reduce costs in automation systems.

So what makes AS-Interface the top choice? Let’s explore the outstanding features of this protocol.

- Simple design: AS-Interface uses a single two-core cable to transmit data and power, reducing installation and maintenance costs.

- Low cost: This system is cost-effective in deployment, especially suitable for small or simple-structured systems.

- Flexible connectivity: Supports connection of up to 62 devices (sensors or actuators) on the same AS-Interface network.

- Scalability: Easy integration with higher-end industrial communication systems such as PROFIBUS, PROFINET, or Ethernet/IP.

- Stable performance: Meets communication requirements in harsh industrial environments thanks to its high anti-interference ability.

Comparing AS-Interface with other industrial communication protocols

AS-Interface (AS-i) has outstanding features suitable for simple and low-cost applications, but compared to other popular industrial communication protocols such as PROFINET, Ethernet/IP, Modbus, or CANopen, each protocol has its own advantages and disadvantages. Below is a detailed comparison table:

| AS-Interface | PROFINET | Ethernet/IP | |

| Main Applications | Simple Sensor and Actuator Connection | Complex and Real-Time Automation | Large-Scale Automation and Monitoring |

| Data Rate | 167 kbit/s | Up to 100 Mbit/s or higher | Up to 100 Mbit/s or higher |

| Data Transmission Distance | Up to 100m | Up to 100m (Standard Ethernet) | Up to 100m (Standard Ethernet) |

| Number of Devices | Up to 62 devices per network | Unlimited (depending on configuration) | Unlimited (depending on configuration) |

| Installation costs | Low | High | High |

| Scalability | Limited (up to 62 devices) | Very Flexible | Very Flexible |

AS-Interface is a suitable choice for simple and low-cost applications, mainly in basic sensor and actuator connection systems. If the system requires high speed, scalability and strong integration, protocols such as PROFINET or Ethernet/IP are the optimal choice.

What should you pay attention to when using AS-Interface?

When using AS-Interface (AS-i) in an automation system, you need to pay attention to some important factors to ensure efficiency and reliability in operation.

- Device number limit: An AS-Interface network only supports a maximum of 62 devices. If the system needs to connect more devices, you must expand by adding AS-i networks or using a network extender (Gateway).

- Transmission distance: AS-Interface only supports a maximum distance of 100m between the master and the last device. If you need to expand, you can use a repeater to increase the distance.

- Compatibility: Check that the device is compatible with the AS-Interface standard and supports the versions you use (for example: AS-i Version 2.1 or AS-i Version 3.0).

- Maintenance and Routine Testing: Although AS-Interface is simple in design, regular maintenance is still required to check the cables, connections, and data transmission performance.

- Consider cost and system needs: AS-Interface is suitable for small, simple systems. For complex or large-scale systems, consider combining or replacing with other protocols.

How is AS-Interface applied?

AS-Interface (Actuator Sensor Interface) is widely used in automation systems due to its simplicity, low cost, and efficiency in connecting sensors and actuators. Here are some specific applications of AS-Interface in industries:

Automotive manufacturing and assembly

- Connecting sensors and actuators on automated assembly lines, such as position check sensors, emergency buttons, or signal light systems.

- Control and monitoring of industrial robots in welding, painting, and assembly lines.

Food industry

- Integrating level sensors, pressure sensors, and control valves in bottling, processing, or packaging lines.

- Monitoring the status of machines such as conveyors, filling and capping systems.

Packaging and logistics

- Connecting optical sensors to detect objects on conveyors or in automatic sorting systems.

- Control servo motors and lifting/lowering systems in packaging machines or picking robots.

Chemical and pharmaceutical industries

- Monitor and control chemical or pharmaceutical production lines’ temperature, pressure, and flow sensors.

- Connect actuators that control valves, mixers, and conveyors.

Mining Industry

- Control of long conveyor systems and load cell monitoring in the mining industry.

- Integration of vibration, pressure, and actuators in crushing and screening equipment.

Conclusion

AS-Interface is an ideal solution in the field of automation thanks to its simplicity, low cost and high efficiency in connecting sensors and actuators.

With its easy and economical installation, AS-Interface has become the first choice for small to medium-sized automation systems, especially in industries such as manufacturing, water treatment, packaging and logistics.

However, limitations such as limited number of devices, low data transmission speed and limited scalability make AS-Interface unsuitable for complex or large-scale automation systems. Therefore, when choosing a communication protocol, businesses need to carefully consider the system’s requirements to optimize efficiency and operating costs.