What is the Hydraulic servo system? In the field of industrial automation, hydraulic servo systems play a crucial role in applications that require high power, precision, and rapid response. These systems combine hydraulic power with servo control to provide precise force, speed, and position, making them essential in industries such as aerospace, robotics, heavy machinery, and manufacturing.

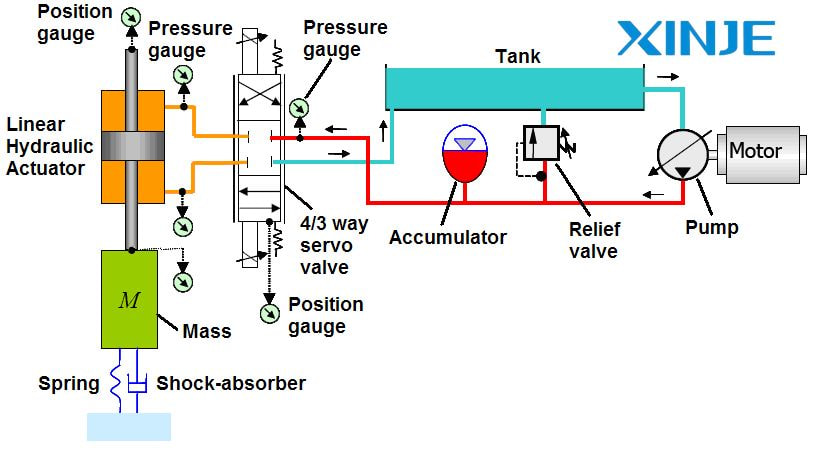

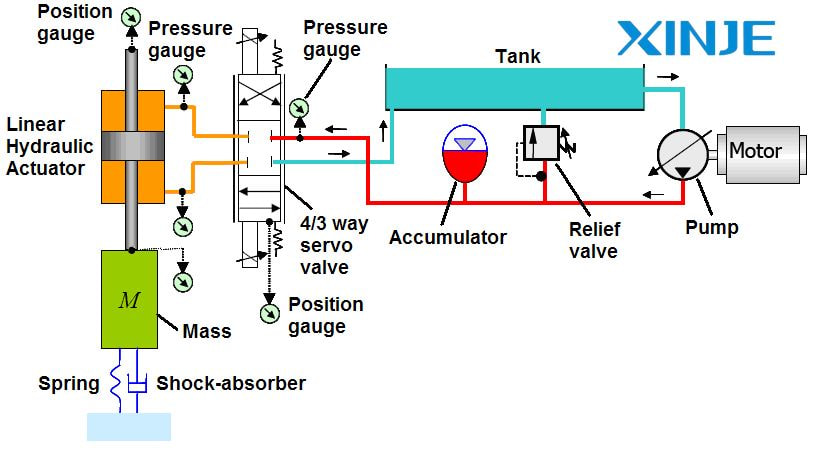

A hydraulic servo system typically consists of a servo valve, an actuator (such as a hydraulic cylinder or motor), a position sensor, and a controller. The system responds dynamically to input signals, adjusting hydraulic flow and pressure to maintain the desired performance in real time. Compared to traditional hydraulic systems, servo systems are significantly more responsive and intelligent, capable of handling complex movements with high precision.

What is the function of a hydraulic servo system?

The main function of a hydraulic servo system is to precisely control the movement of a load by adjusting the hydraulic pressure and flow based on feedback and control signals. Its main functions include:

- Position control: The system can accurately position the load, even when subjected to changing external forces. This is important in CNC machinery, injection molding, and metal forming processes.

- Velocity control: The hydraulic servo system can smoothly and consistently adjust the speed of the actuator, making it ideal for applications that require dynamic motion.

- Force or pressure control: With built-in sensors, the system can maintain or vary the output force with exceptional precision, commonly used in pressing, clamping, and tensioning operations.

- Closed-loop feedback: Unlike open-loop hydraulic systems, hydraulic servo systems operate in a closed-loop configuration, continuously comparing output performance to target inputs and making real-time adjustments for greater accuracy.

These features make hydraulic servo systems indispensable in industrial automation tasks that require optimum precision and must meet high tolerance standards.

How does a hydraulic servo system work?

Hydraulic servo systems operate through the integration of electronic control and hydraulic transmission. The operation process takes place through the following steps

- Receiving input signals: The system receives command signals, usually voltage or current, indicating the desired position, speed, or force.

- Electronic controller: This signal is processed by the servo controller, which compares it with real-time feedback from sensors (usually position sensors or pressure sensors).

- Servo valve activation: Based on the controller’s calculations, the servo valve adjusts the flow and direction of hydraulic fluid toward the actuator. The servo valve is highly sensitive and can fine-tune the hydraulic output.

- Access feedback: The hydraulic actuator (cylinder or motor) moves the corresponding load. Its motion is continuously monitored and corrected based on the feedback loop.

- Feedback mechanism: The feedback sensor sends information about the actual position or force back to the controller, which then makes further corrections if necessary.

This continuous feedback control loop of Hydraulic servo systems ensures highly accurate motion and output force, even under changing load or environmental conditions.

What are the 4 hydraulic systems?

Open-Center System

In an open-center system, the fluid flows continuously through the control valve and returns to the reservoir when no actuating function is being performed. It’s simple and commonly found in mobile hydraulic equipment.

Key Features

- Constant Pump Operation: The hydraulic pump runs continuously and delivers a steady flow of fluid regardless of system demand.

- Lower Cost and Complexity: With fewer control components and no need for pressure-compensated valves, open-center systems are economical to build and maintain.

Closed-Center System

A closed-center hydraulic system is a more advanced and energy-efficient configuration compared to open-center systems. In this setup, hydraulic fluid does not flow continuously when the system is in the neutral position. Instead, the control valves block the flow of fluid, and the pump either stops or maintains pressure without circulating fluid unless an actuator demands it.

Key Features:

- Energy-Efficient Operation: Because the pump only supplies fluid when needed, less energy is wasted during idle times.

- Better Pressure Control: Closed-center systems are capable of maintaining consistent pressure across multiple actuators.

- Supports Multiple Functions Simultaneously: With pressurized fluid readily available, multiple actuators can operate independently and simultaneously without waiting for fluid to recirculate.

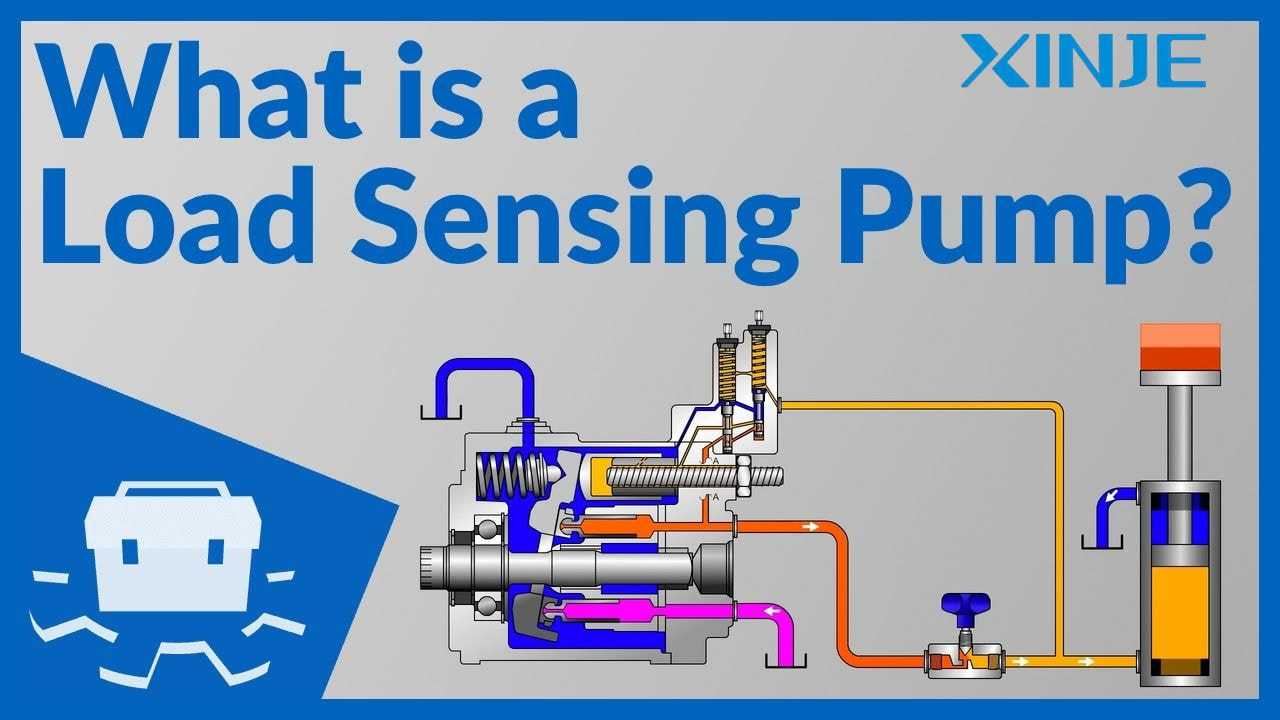

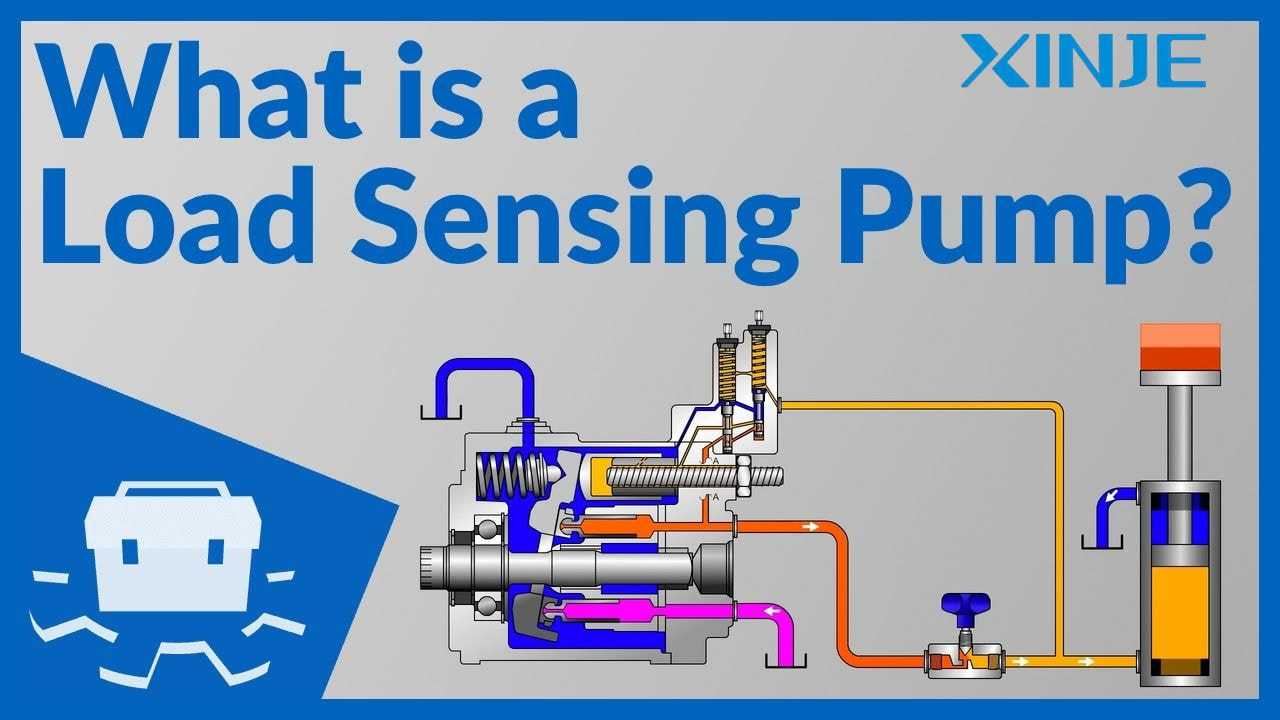

Load-Sensing Hydraulic System

A load-sensing hydraulic system is a sophisticated evolution of the traditional hydraulic circuit, designed to match hydraulic output precisely to the demand of the load. Instead of delivering a constant flow or pressure, the system intelligently adjusts the pump’s displacement and control valve operation based on the actual needs of each actuator at any given moment.

Key Features:

- Demand-Based Flow and Pressure Control: The pump does not run at full capacity unless needed. It continuously adjusts its output based on real-time feedback, ensuring that only the necessary amount of fluid and pressure is supplied to meet current system demands.

- Reduces Energy Waste and Heat Generation: Because the pump isn’t working unnecessarily, there is significantly less power consumption during low-load or idle periods.

- Enhances System Precision: Load-sensing systems respond more accurately to variable loads and multi-actuator control, offering smoother transitions, better synchronization, and improved operator control.

What should be noted when using a Hydraulic servo system?

Operating a hydraulic servo system requires not only technical knowledge but also careful planning and regular maintenance. Here are some important considerations to ensure safe, reliable, and optimal performance:

- Oil cleanliness: Servo valves are very sensitive to contamination. Even small particles can clog the internal passages and reduce performance.

- Correct control loop tuning: Servo systems rely on PID or advanced control algorithms. Improper tuning can lead to overloads, oscillations, or instability.

- Regular inspection and preventive maintenance: Hydraulic pipes and sensors can wear out over time, so regular maintenance and inspection are necessary

- Proper integration with the control system: operators can use a number of compatible communication protocols such as Modbus, CANopen, or EtherCAT to ensure the servo controller communicates properly with your PLC or industrial PC.

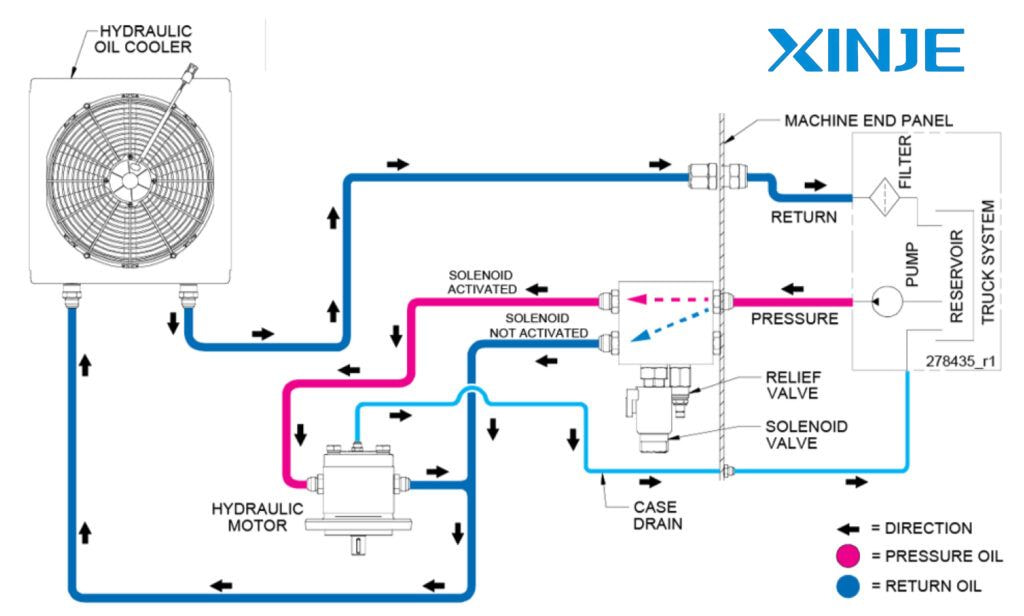

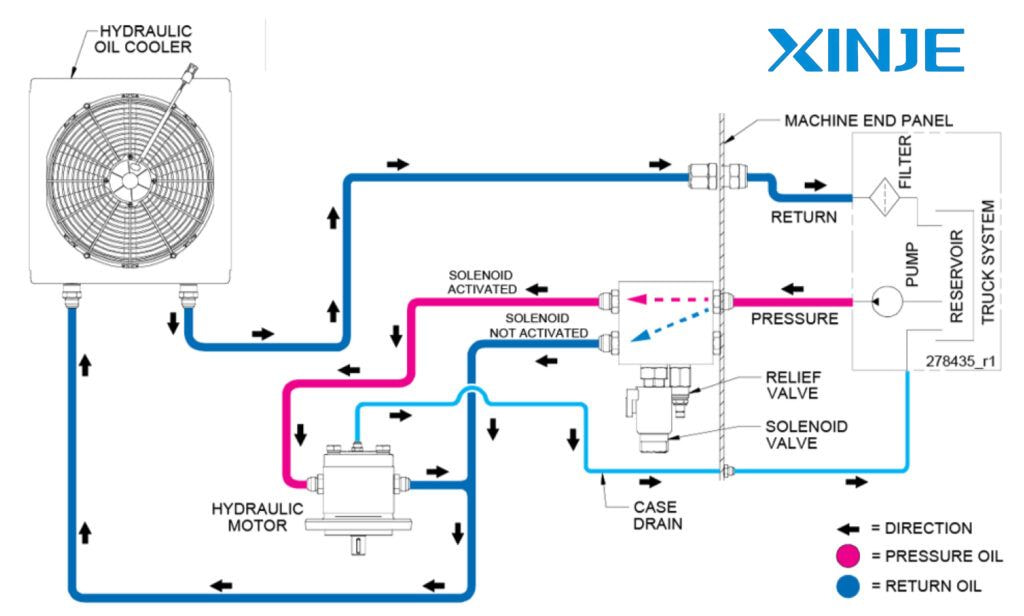

- Temperature Monitoring: If the temperature is too high, it can damage the seals and reduce the viscosity of the fluid in the system. Users should consider using a temperature sensor and a cooling system if necessary.

Conclusion

Hydraulic servo systems play an indispensable role in modern industrial automation, where precision, power, and responsiveness are non-negotiable. By combining the raw strength of hydraulics with the intelligence of feedback control systems, they allow factories, aerospace systems, and manufacturing lines to operate with unmatched efficiency and reliability.

Whether you’re upgrading from a proportional system or designing a new automation solution, understanding how hydraulic servo systems work, their components, and best practices is key to maximizing performance and minimizing downtime.