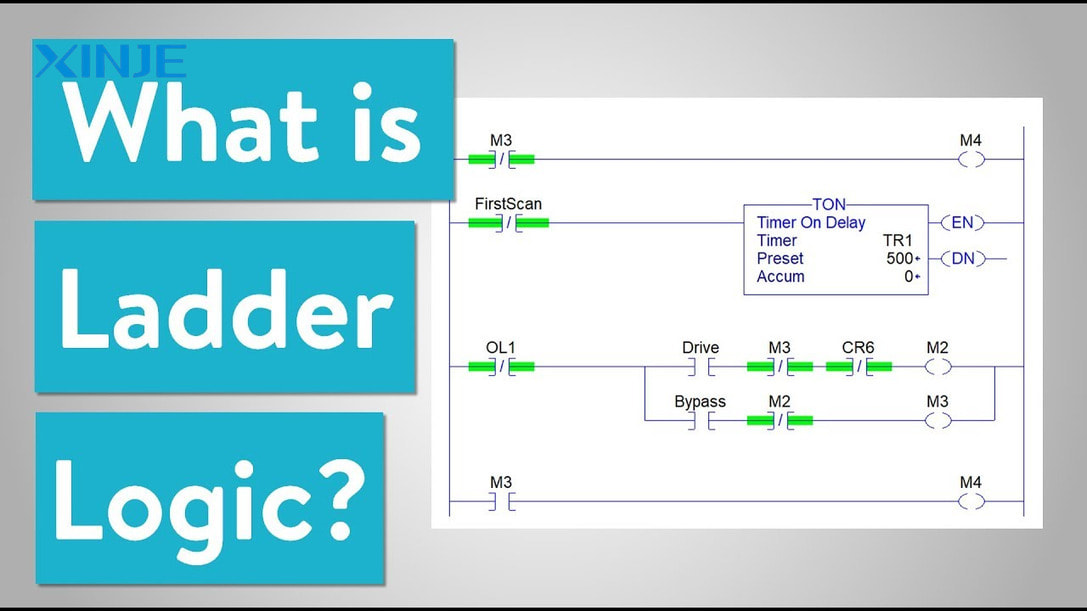

Ladder logic programming is one of the five commonly used languages in PLCs. They are inspired by conventional electrical relay circuits and further developed to optimize many complex industrial processes such as assembly lines, conveyors, packaging, machinery and equipment manufacturing, etc.

It can be said that ladder logic is the program that is preferred over other programming languages thanks to its easy-to-operate interface and outstanding advantages that help improve monitoring and control capabilities to maintain efficiency in the entire system.

To learn more about ladder programming, follow us to the end of the article, you will gain a lot of interesting knowledge about this program as well as how to develop ladder logic systems most effectively.

Where is ladder logic commonly used?

Everyone knows the uses and conveniences of ladder logic programming, but how commonly are they applied? Some common applications of ladder logic programming include:

- Motor control: Ladder logic programming controls the entire operation of the industrial process, from starting, managing, and monitoring the speed and direction of movement of the equipment until stopping the motor.

- Conveyor system: similar to motor control, ladder logic programming is also often used in the operation of conveyor lines in large factories, supporting the deployment and operation of the direction of movement of products on the conveyor, monitoring and automatically stopping operations if any risks occur during operation.

- Assembly line: this programming method is also widely used in the automotive, electrical, and electronic equipment manufacturing industries, specializing in coordinating the operation of robots, picking and placing, and ensuring that each product is assembled in the correct position.

- Packaging and palletizing lines: ladder logic programming in the packaging industry will coordinate with other equipment such as filling machines, cartooning machines, and palletizing machines, the system will help control each operation carefully to ensure that all products are packaged according to pre-defined parameters.

Why is ladder logic becoming popular?

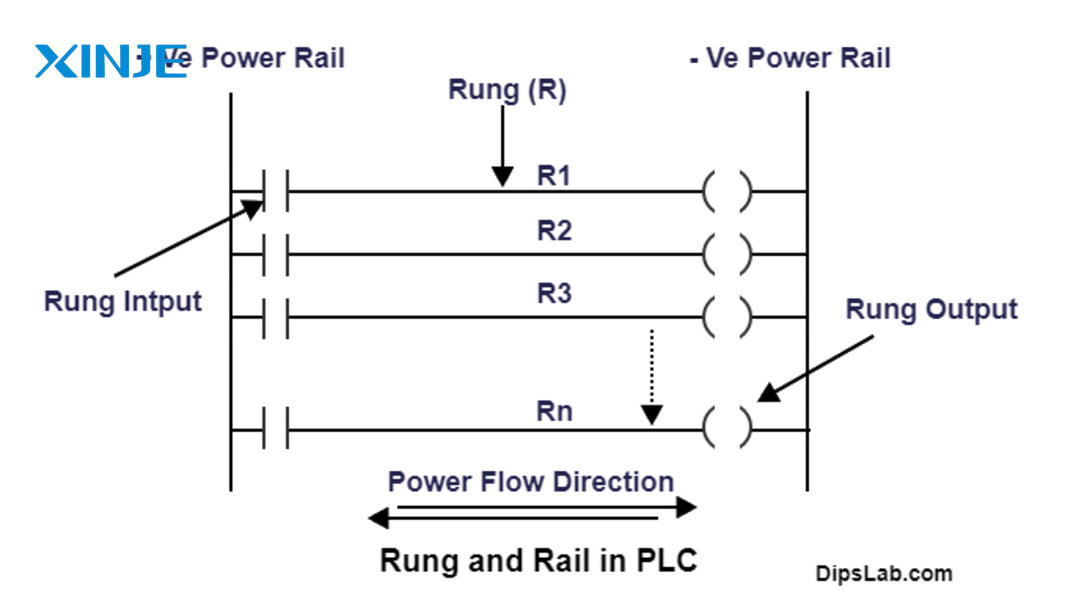

Ladder logic programming is becoming the most popular programming method today thanks to its user-friendly graphical interface, and ease of use, and it looks very similar to relay circuit simulation diagrams. Therefore, most experienced technicians or newbies find it easy to switch from conventional circuits to ladder logic.

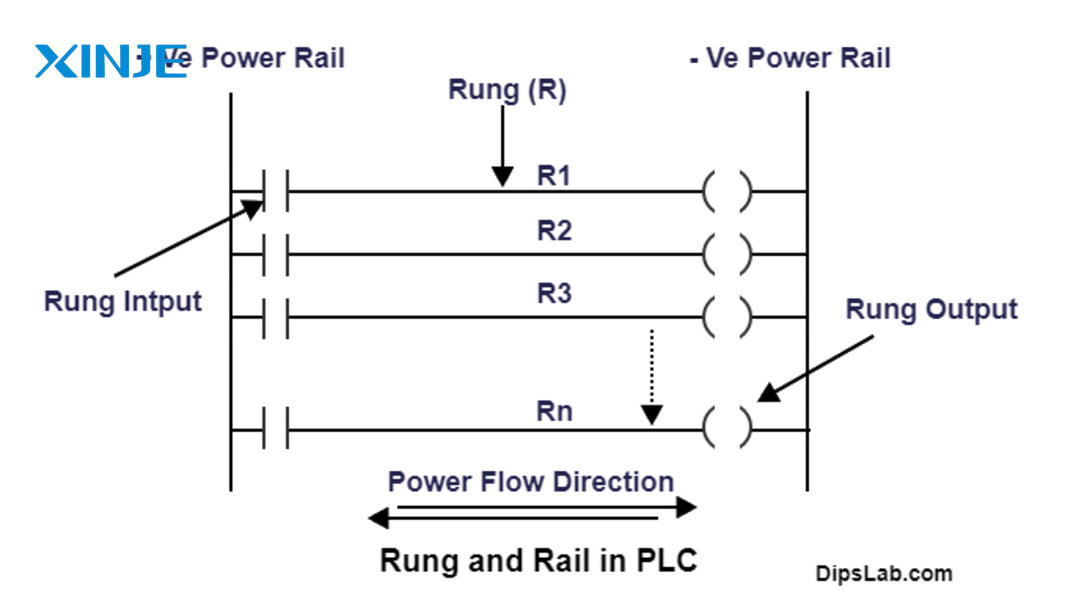

In addition, ladder logic designed in PLC will help you build code quickly, making it easier to troubleshoot problems because we will observe the logic flow from the starting rail on the left to the ending rails on the right.

What are the advantages and disadvantages of ladder logic programs?

Advantages

The advent of ladder logic programming has brought many benefits to automated factories, robots, and other automated production lines with many benefits such as:

- It is easier to debug in the circuit when the technician can directly observe the overall electrical flow and graphics of the entire circuit, making debugging easier and faster.

- Circuits designed by ladder logic programming are more efficient and reliable than other complex electrical components.

- Provide a variety of graphics with high flexibility and functionality, suitable for complex production lines and tasks.

- Easy to monitor, manage, and maintain, suitable for large-scale production units that require advanced programming structures.

Disadvantages

Along with the outstanding features, ladder logic programming also has certain limitations such as:

- Limited data structure: Data is often just single bits or registers, making it difficult to group and protect data.

- Inflexible execution control: Ladder diagrams execute from left to right, top to bottom, making it difficult to build applications that require multi-speed feedback or analog control (such as PID) that requires consistent execution time.

- Limited arithmetic operations: Ladder diagrams still support operations, but they are not as flexible as other tools, especially with complex algorithms, because the input/output of the function block must be referenced through memory locations.

What components does ladder logic include?

Ladder logic is one of the five commonly used languages in PLCs. Each different ladder logic will be made up of several key components, which will directly affect the monitoring and control of the process.

Some of the main components that any ladder logic program has:

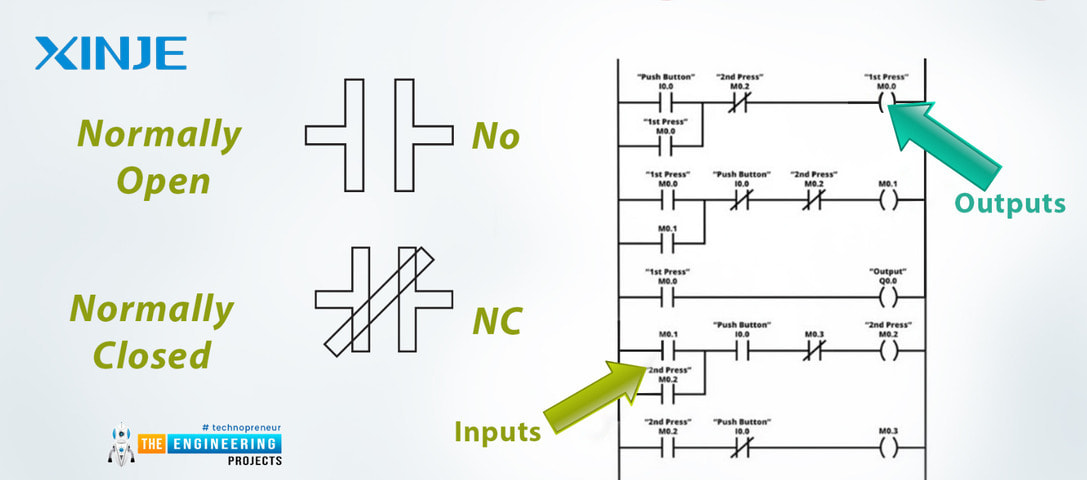

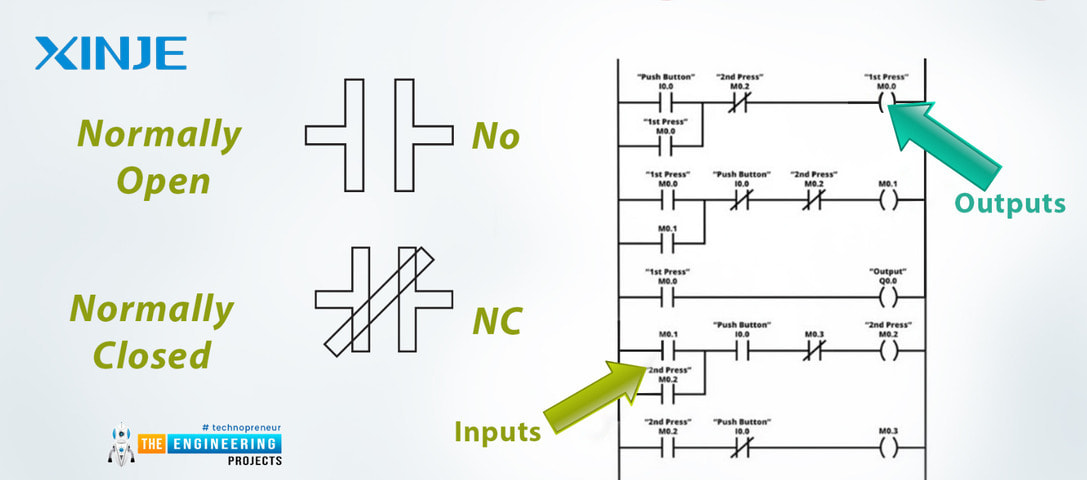

- Contacts: the contact part is usually divided into 2 types: NO – the contact is opened when the input is activated, and NC – the contact is closed when the input is activated. Contacts are considered the basic part of a normal ladder program and are represented through many input devices such as switches, sensors, physical buttons, etc.

- Coils: if the contacts represent input devices, the coil is the part that represents output devices such as motors, solenoids, and indicators. The operation of the coil is similar to that of the contact part, they also have two states: open or closed, this state will be activated or changed depending on the connected output device.

- Timer: Timer includes many classifications such as delay on a timer (TON), delay-off timer (TOF), and hold timer (RTO). Depending on each classification, there will be different goals and usage specifications.

- Counter: Counter is used to control specific actions in the process, they can be an increment counter – increase the number in the process, or can be a decrement counter – decrease the number when an event occurs in the process.

- Math and comparison functions: Ladder logic operates mainly based on mathematical functions, such as addition, subtraction, multiplication, division, and comparison operations (greater than, less than). In particular, this mathematical function will be performed based on the value given by the other parts.

How to develop a complete ladder logic program?

To develop a complete PLC ladder logic program, certain steps must be taken to ensure that the installation will work to meet the requirements that the business desires. These steps include:

- Planning and design: You should prioritize planning to clearly define the input and output devices, the operating process, and the desired control logic. Planning and creating a complete flow chart of the process will help you visualize the operating mechanism easily identify potential errors and edit them.

- Choose a programming language: ladder logic programs have many different programming languages such as LD (Ladder Diagram), ST (Structured Text)… And of course, you cannot randomly choose any programming language. You need to rely on the complexity of the process, the desired goals, and the programmer’s compatibility with the device. Therefore, you should prioritize choosing the language that suits the project’s specific requirements.

- Write the program: At this step, you will start programming, creating ladder logic diagrams, implementing timers, mathematical functions, and modular programming. However, please note that you must follow the regulations in using naming conventions or applying appropriate documentation to ensure that the program is written in a way that is easy to understand and easy to maintain in the future.

- Test and debug (if any): Once you have finished writing the program, test it again to easily detect and promptly edit any errors. At this step, any errors in the program must be identified and edited immediately to avoid affecting the performance of this operation later.

- Deploy: After completing the above steps including thorough testing and debugging, the program can be deployed into the system to monitor and control your operations.