Counters and Timers are important and common functions in PLC programming, they allow time control and tracking of the number of events in the entire automation system. These functions help to optimize the process, reduce system complexity, and bring high accuracy and efficiency. To learn more, let’s explore the characteristics, features, advantages and disadvantages, and typical differences between counters and timers.

What is the counter in PLC?

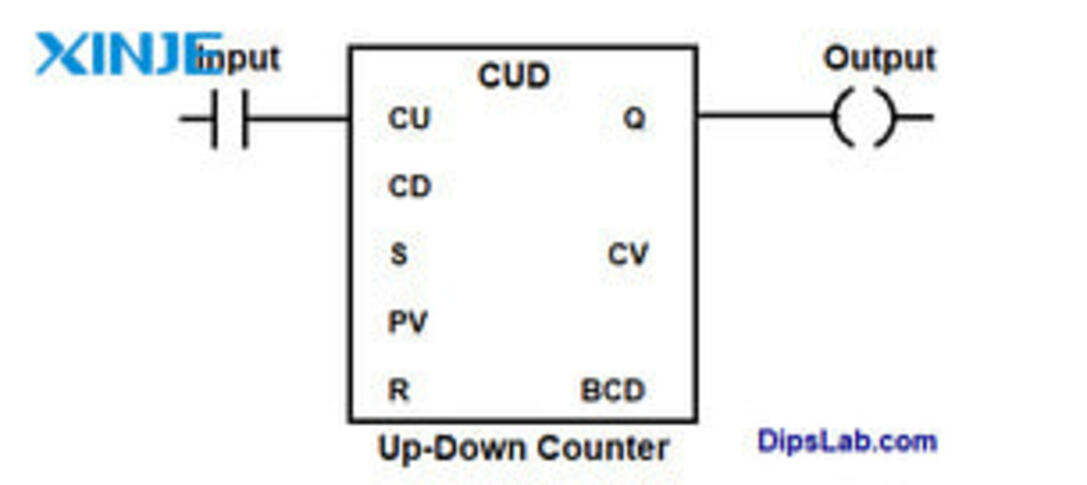

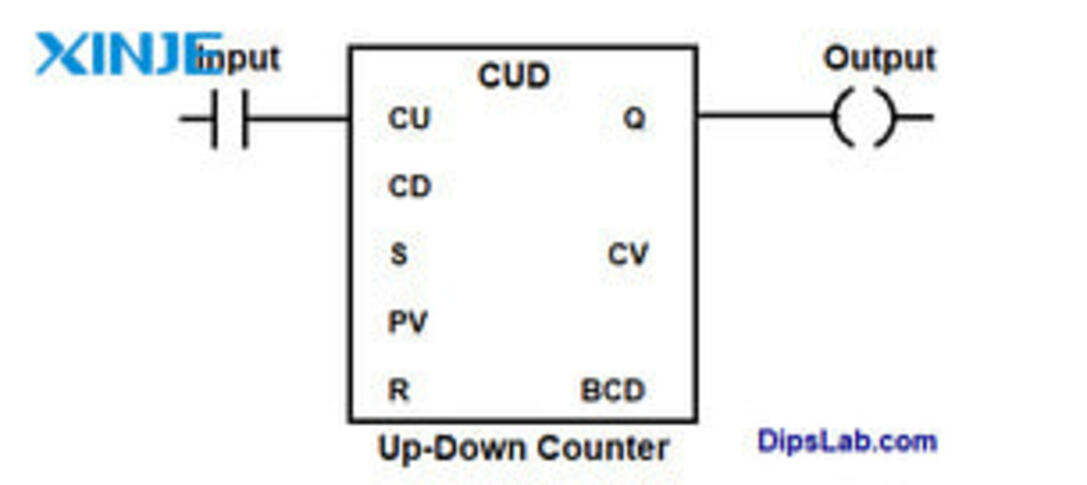

Counters in PLCs are devices used to track events such as products through sensors or completed machine cycles. Unlike timers, counters operate based on external trigger signals or program logic, helping to track events accurately in many applications. In particular, counters in PLCs are often divided into two common types:

- Count Up (CTU): They usually record events by increasing the value each time the event occurs. When reaching the set value, the output will be activated and the contact state will change, suitable for tracking the number of products through sensors, especially in quality control systems.

- Count Down (CTD): This function decrements the counter when an event occurs, suitable for monitoring the remaining quantity in applications such as tracking the number of unfinished products in a batch or coordinating work sequences…

What is the timer in PLC?

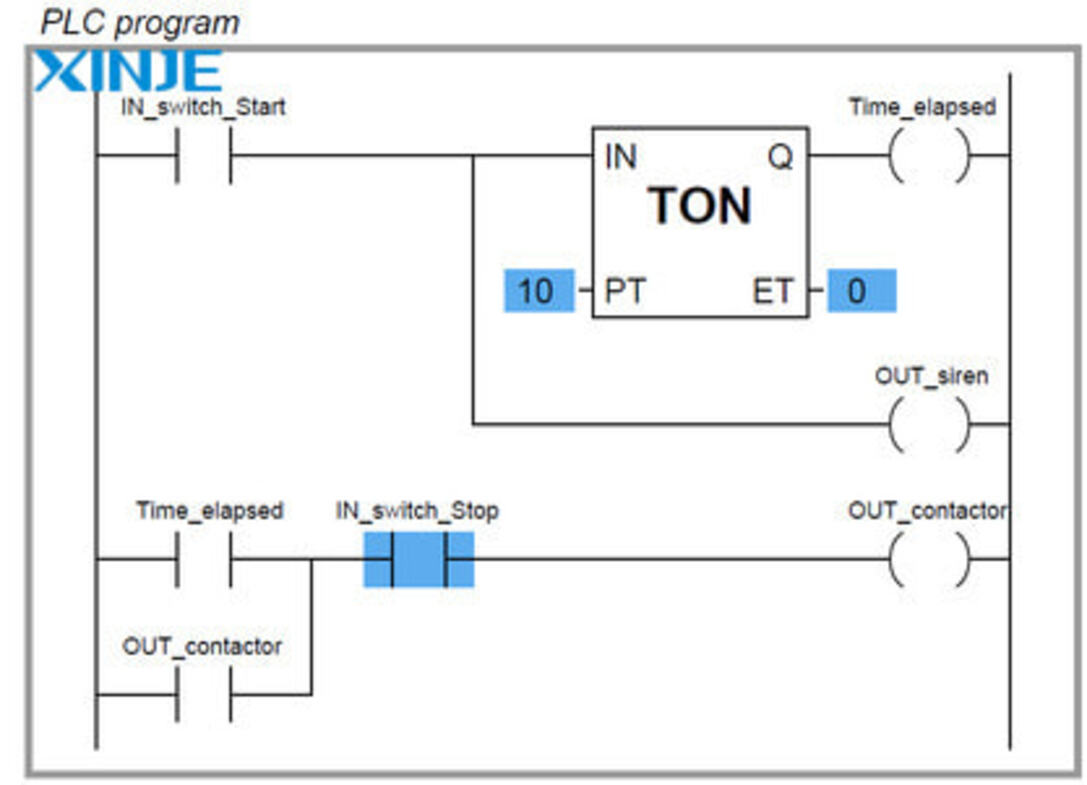

A PLC timer is a programmable device that creates a delay or controls the timing of various operations. It is similar to a traditional time relay, but a PLC timer provides greater accuracy and flexibility with settings such as time base, preset value, and cumulative value. In addition, two common functions of timers are:

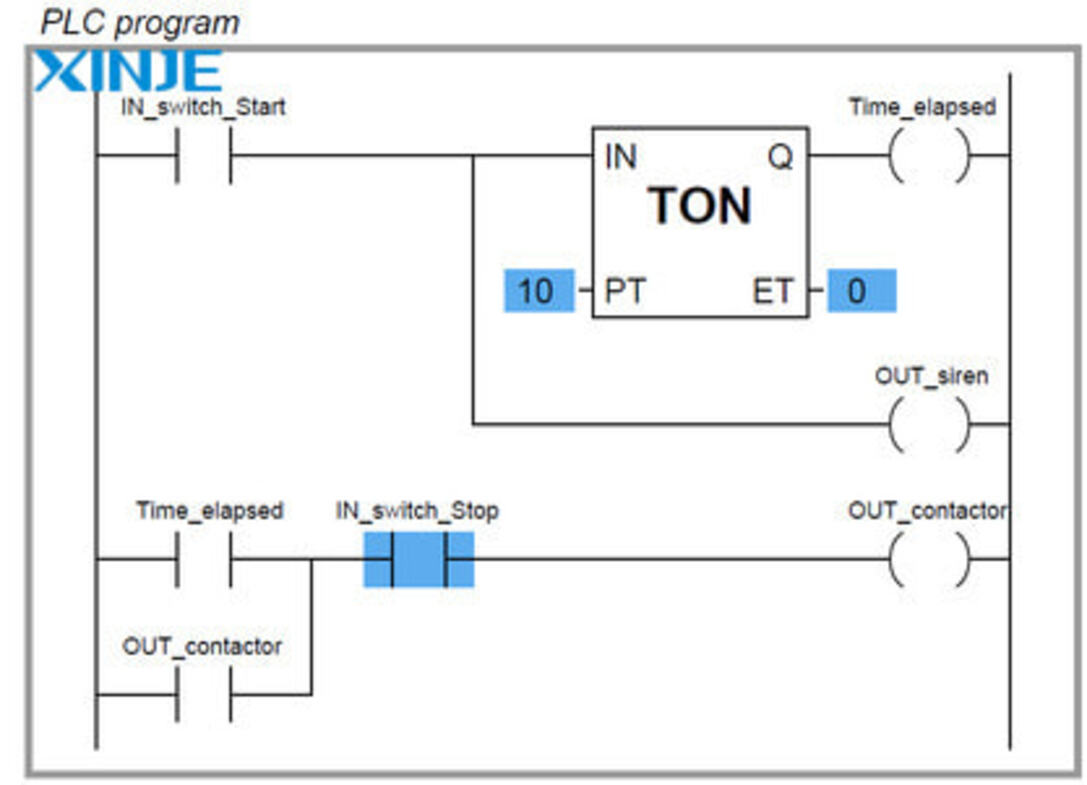

- Timer On-Delay (TON): This function will usually start counting when a logic condition is met. When the set value is reached, the output is activated and the contact is updated. It is mainly used for delaying operations, such as waiting for the process to complete before the conveyor runs.

- Timer Off-Delay (TOF): The delay off-timer starts counting when the signal is disabled. After the set value is reached, the output is turned off and the contact returns to its original state. This function is applied to keep the operation for a while, such as keeping the light on after the switch is turned off.

How are counters and timers different?

Counters and timers are both time-related devices that are widely used and popular in many different areas of life such as road traffic, factory production lines, management, and monitoring… However, there will be certain differences between these two devices such as:

| Counters | Timers |

| Based on external signals to perform pulse counting | Use the frequency of the internal clock to create the delay |

| To measure the frequency of a signal, you can start by counting the number of pulses received in one second, thereby determining the frequency of the unknown signal. | The frequency is fixed, allowing an interrupt signal to be generated after a certain period. |

| The maximum counting speed is equivalent to 1/12 of the oscillation frequency. | The maximum counting speed is equivalent to 1/24 of the oscillation frequency. |

| This register is incremented after each machine processing cycle. | The register will increment when there is a transition from level 1 to level 0 at the corresponding external input pin (T0, T1). |

| Commonly used to measure and monitor time intervals. | Often used to record the number of events via an external signal or an internal clock. |

| Commonly used in traffic monitoring, production line management, and monitoring. | Often used in cooking, sports activities, and event scheduling management |

What are the advantages and disadvantages of counters and timers?

Advantages

- Easy to install and use: the devices can be integrated into the system with simple programs and do not require too many complicated techniques.

- High flexibility and accuracy: counters and timers meet many time-related tasks such as measuring events, generating precise signals, or triggering activities at predetermined times accurately.

- Reduced coding complexity: They will help simplify the coding process, save development time, and limit errors during the process.

- Cost-effective: Reduce the need for other hardware or peripherals, helping to save budget during operation.

Disadvantages

- Limited computational capabilities: Not all controllers have built-in counters or timers, so relying on them can limit your choice of microcontroller.

- Reduced control: Resolution and time-interval adjustment are limited, making it difficult to meet special requirements.

- Added complexity: Configuration and setup can be more complex than using other programming methods, making development more difficult.

What is the development trend of counters and timers?

Counters and timers in PLCs are increasingly focusing on creating modern and easy-to-use features that are suitable for current technology development trends such as:

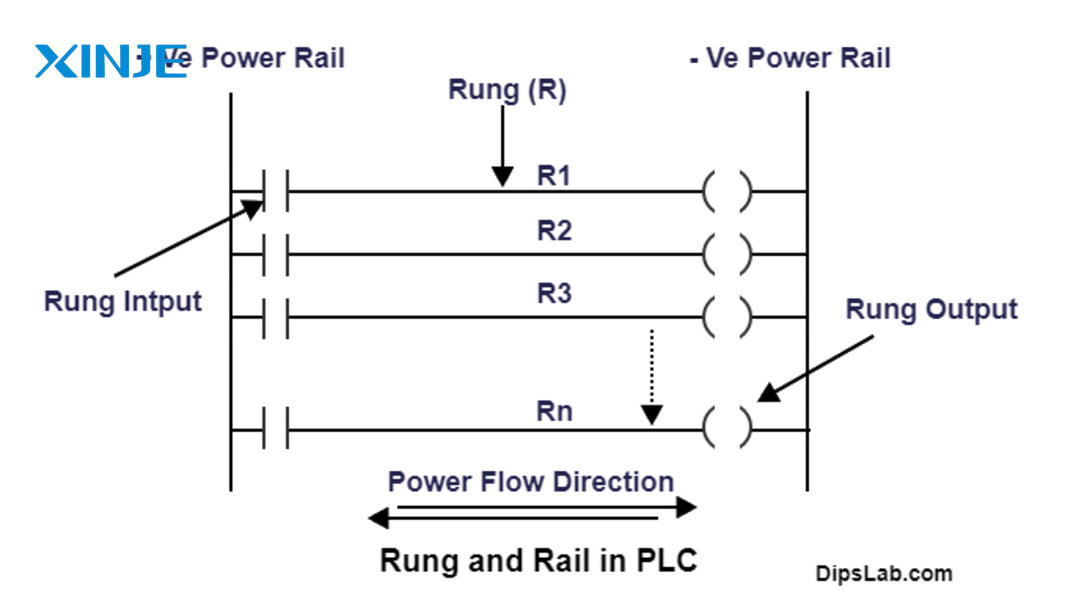

- Friendly interface: Counters and timers in PLCs are designed with intuitive graphical interfaces, such as ladder logic diagrams, bar charts, or digital displays, to help operators easily manage and monitor the device’s status.

- Connection and integration: PLCs can be paired with many devices via Ethernet, Modbus, and Profibus protocols to help synchronize data and commands with devices such as sensors, HMIs, SCADA, and MES systems. Counters and timers can also be collected and analyzed more easily.

- Security and reliability: PLCs are now integrated with advanced security features such as encryption and authentication. At the same time, the ability to backup, redundancy, and error prevention will help counters and timers operate stably throughout the process.

Customization and Innovation: PLCs have enabled users to create custom counters and timers using a variety of programming languages such as Python or Java. Additionally, AI, machine learning, and cloud computing features are also integrated so that counters and timers can learn from data and adapt to changing conditions.