What is an HMI Upgrade? An HMI upgrade involves replacing or updating the software, firmware, or hardware components of your HMI system. This could mean installing the latest firmware version, upgrading the HMI programming software, or even migrating to a more advanced HMI panel that supports advanced features like remote access, enhanced graphics, or integration with newer PLCs.

An upgrade can be as simple as applying a security patch or improving the responsiveness of the UI with a firmware update. Some common types of HMI upgrades include: firmware upgrades, software or hardware upgrades, and system migrations.

What are the benefits of upgrading the HMI system software?

Updating your HMI system software offers many benefits, including technical, operational, and efficiency advantages.

- Improved performance: Modern software and firmware versions are optimized for faster processing, smoother user interfaces, and reduced latency when communicating with the PLC.

- Improved security: Manufacturers release software patches to address security vulnerabilities in areas such as food processing, pharmaceuticals, and critical infrastructure.

- Compatibility with new devices: Upgrades ensure that your HMI supports the latest PLC protocols such as OPC UA, MQTT, Ethernet/IP, or SCADA sensors and systems.

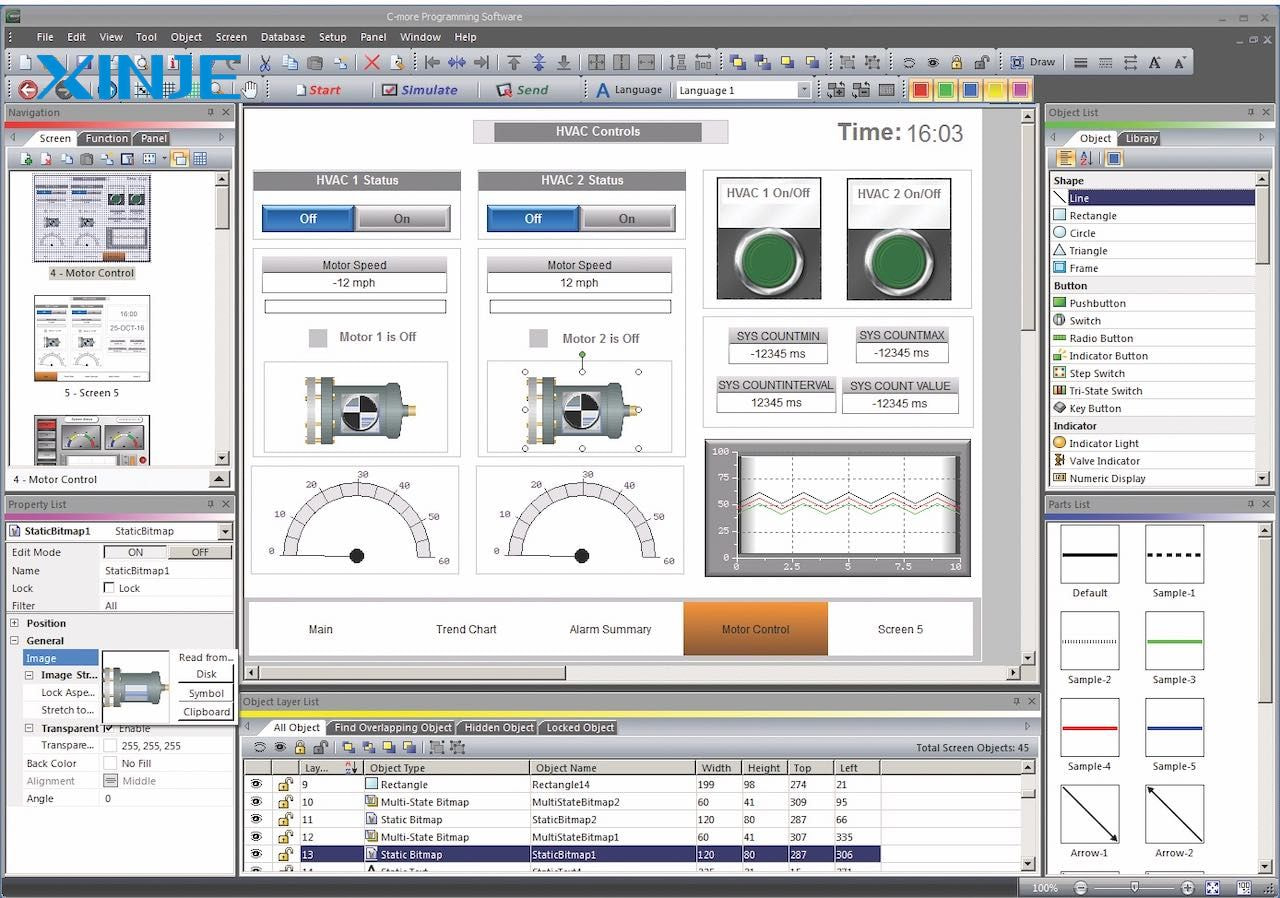

- Improved user interface: New HMI versions often introduce advanced graphics features, multi-touch capabilities, and customizable control panels for a better operator experience.

- Bug fixes and stability: Software updates often address known issues such as frozen screens, lost connections to the PLC, or reboot loops.

When should I update my HMI system software?

So the question is, “When is the best time to update an HMI?” Upgrading a software system depends on many factors, such as performance, new features, security alerts, etc.

- Decreased performance: Slow screen response, delayed warning messages, or frequent crashes are clear signs that your HMI system needs an update.

- Integration needs: If operators want to integrate with a new PLC or SCADA system and encounter compatibility issues, then upgrading the system should be considered.

- Security alerts: If your IT or OT cybersecurity team reports a vulnerability related to the current firmware, then immediate action is required.

- New feature requests such as remote access, alarm history, comprehensive visibility, etc. Most of these requests require updated software or firmware support.

How to update the latest HMI firmware?

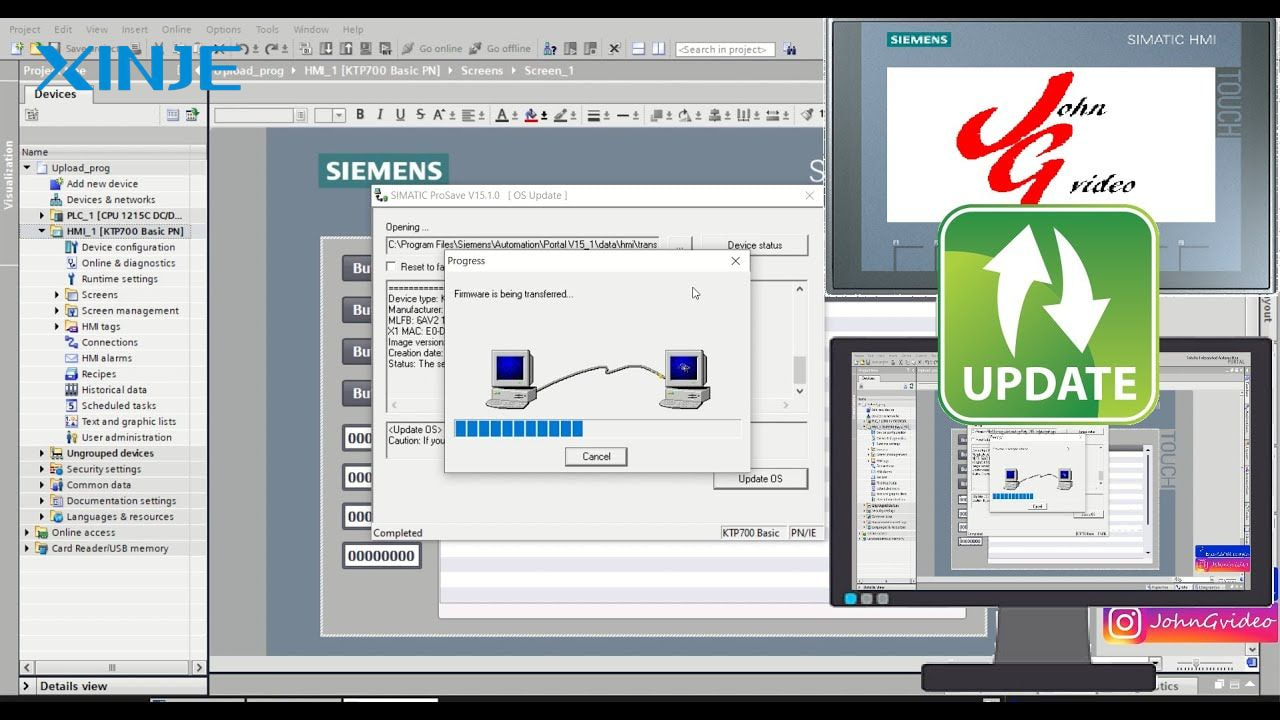

Updating HMI firmware varies by brand and model, but the general process is similar across platforms such as Siemens, Allen-Bradley, Schneider Electric, and Delta. Here is a general guide to help you through the update process.

Note: Always back up your HMI project files before performing any updates.

- Step 1: Identify your HMI model and current firmware version by locating the model number on the HMI device or checking through the system setup menu.

- Step 2: Visit the manufacturer’s Support Site, searching for firmware downloads specific to your HMI model. For example: Siemens Comfort Panel, Rockwell PanelView, etc.

- Step 3: Download the firmware and update tool. For example: TIA Portal for Siemens, FactoryTalk for Allen-Bradley.

- Step 5: Backup the current HMI Configuration and use the configuration software to export the current HMI project, storing it securely on your engineering workstation or network drive.

- Step 6: Install the Firmware and run a functional test to ensure normal operation.

Conclusion

Updating your HMI system software is not just a maintenance task, but a proactive measure to ensure the security, performance, and scalability of your automation setup. Whether you are updating firmware to fix a bug or upgrading to support a new protocol, the process pays off in improved uptime and functionality.

If you are unsure about compatibility or procedures, consult your HMI vendor or automation integrator for proper support. And remember, investing time in proper update procedures now can save hours of downtime later.