In modern automated factories, HMI Tag plays an important role in connecting data between control devices such as PLC, sensors and HMI interfaces. Understanding HMI Tag Definition correctly, how to classify and manage tags will help engineers operate production lines more effectively, limit errors and optimize system maintenance costs.

What is HMI Tag Definition?

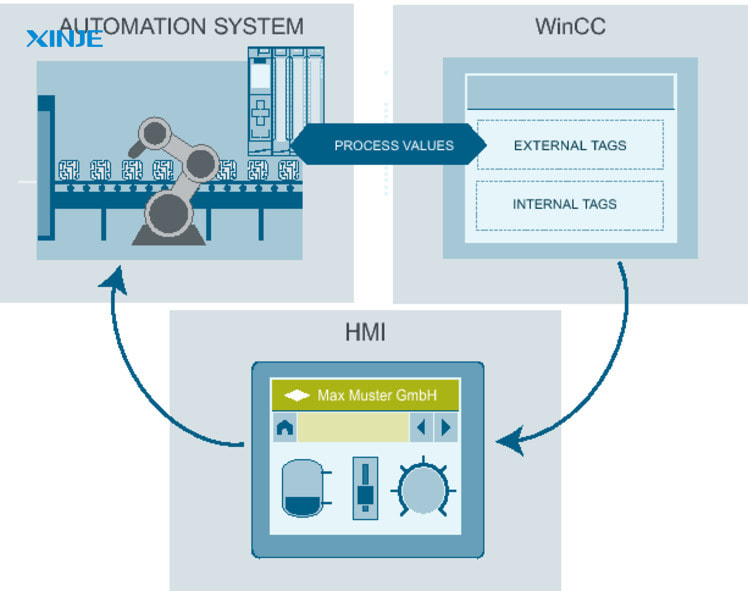

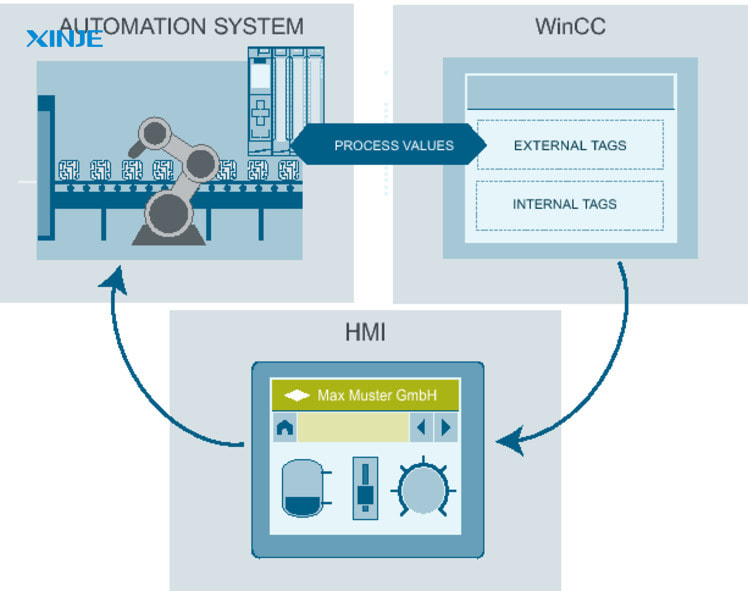

HMI Tag is a basic component in the Human Machine Interface (HMI) system. The tag acts as a “data label”, helping to store and exchange information between automation devices such as PLC, sensors, inverters with HMI software.

Simply put, each tag represents a data variable: switch status, sensor value, control signal, etc. From there, HMI displays visual information, helping to operate and monitor the production line easily and accurately.

Main function of the tag

- Data storage: Each tag stores input/output values such as ON/OFF signals, temperature values, pressure, motor speed, etc.

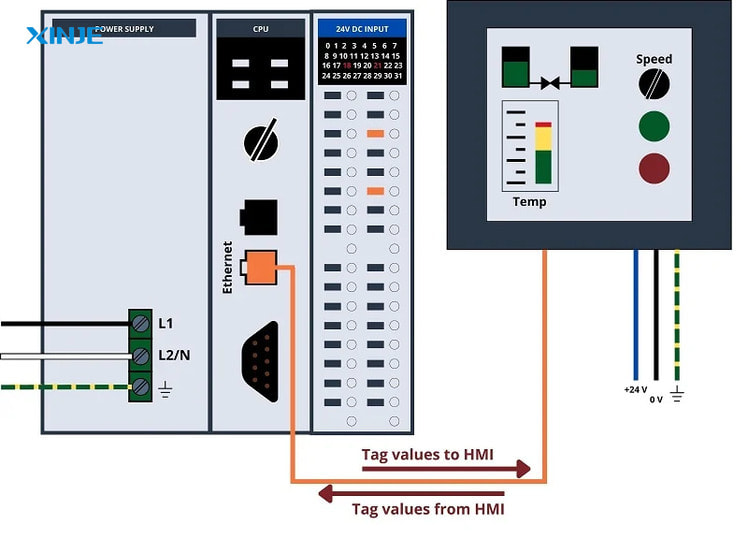

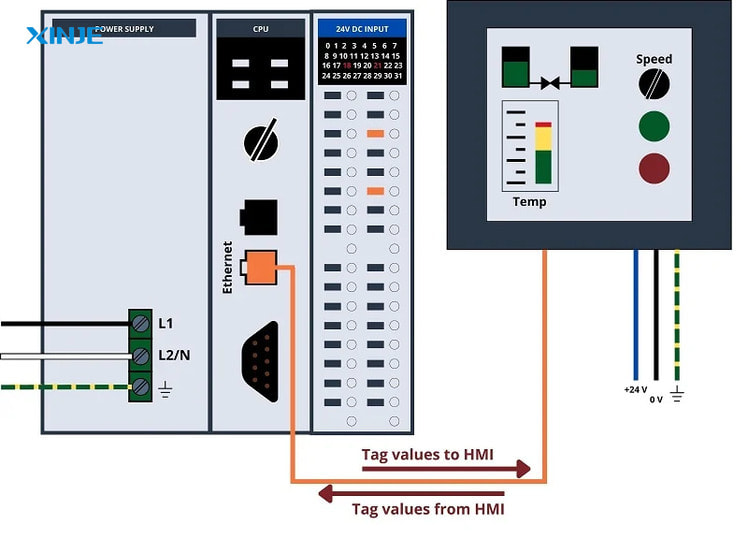

- Data exchange: The tag is a “bridge” to transmit data between PLC, field devices and HMI for display, monitoring and control.

Thanks to tags, all parameters in the production line are synchronized, remotely monitored and automatically processed, ensuring efficiency and safety.

HMI Tag Definition is divided into how many types?

In the HMI system, tags are divided into 3 types to suit the purpose of storing, processing and transmitting data. Clear classification helps programming engineers easily manage, maintain and expand the system.

Internal Tag

- These are tags created and used internally in the HMI software.

- Not directly linked to external devices such as PLCs or sensors.

- Often used to temporarily store intermediate values, logic variables, test conditions or signal flags.

- Helps reduce the load on the PLC, saving communication resources.

- Increase flexibility in HMI interface design.

External Tag

- These are tags that directly connect to peripheral devices such as PLCs, sensors, I/O modules.

- Each External Tag is usually assigned a physical address in the PLC or control device.

- Often contains important data such as: motor status signals, tank levels, pressure, temperature, etc.

- Accurately reflects actual data in the production line. Is the “bridge” between the physical world and the monitoring system on the HMI.

System Tag

- These are tags automatically created by the HMI system.

- Manage information related to the HMI itself: system time, user status, display language, network connection status.

- Increase the ability to manage system operations.

- Support displaying installation information, security, and error reporting automatically.

What is the role of HMI Tag in an automatic production line?

In modern production lines, HMI Tag plays an important role as the “language of communication” between humans and machines. Thanks to the tag, all information from field devices such as sensors, motors, conveyors, and industrial robots are collected, displayed, and processed accurately.

- Record device status: Each tag reflects ON/OFF signals, liquid level, pressure, rotation speed… helping engineers monitor how the machine is operating.

- Transmit control signals: When operating, the tag receives commands from the operator via HMI, then sends them to the PLC to close/open valves, start motors, adjust speeds…

- Display visual data: The tag is linked to graphic objects on the HMI screen such as gauges, indicator lights, trend charts. All fluctuations are easily observed, errors are detected promptly.

- Warning and data storage: The tag is the foundation for the alarm function (Alarm), saving operating history (Data Logging). From there, businesses can easily trace, analyze and optimize the process.

What are the benefits of effective HMI Tag management?

Tag management in HMI is not only a technical matter, but also directly affects the operational efficiency, cost and safety of the production line. If tags are organized and maintained scientifically, businesses will enjoy many obvious benefits:

- Saving system resources: Managing a reasonable number of tags helps optimize the memory and processing speed of the HMI. Limiting memory overflow, screen freezes or slow signal response.

- Easy to maintain and expand: The tag system is named and grouped clearly, making it easy for engineers to search, edit or add new ones when upgrading equipment or changing the production process.

- Increase transparency, easy handover: For businesses operating large production lines, having a standard tag list (Tag List) makes it easy to handover, train new engineers or coordinate with maintenance contractors.

- Optimize monitoring & reporting: Effective tag management makes it easy to set up reports, store operating history. Transparent data supports maintenance departments and production managers to make optimal decisions.

What are the notes when defining HMI Tags that users should know?

To ensure the HMI system operates stably and is easy to manage, programming engineers need to pay attention to some important points when defining tags:

- Name tags clearly and consistently: Tag names should reflect the correct function: For example: Motor_Start, Tank_Level, Alarm_Status… Use prefixes by group: MTR, VLV, SEN for easy classification.

- Determine the correct data type: Tags must be selected according to the correct type: Bool, Int, Float… compatible with PLC. Avoid errors in data type causing hangs or incorrect display values.

- Declare the correct PLC address: With External Tag, the communication address must match the PLC (for example: I/O address, register). Check carefully when changing PLC or expanding modules.

- Manage the number of tags reasonably: Do not create too many unnecessary tags to avoid wasting HMI memory. Group tags by area and device for easy maintenance.

- Regularly check and update: When the line changes equipment, adds new measuring points → need to review the tag. Maintain a clear tag list document for easy handover and maintenance.

What is the practical application of HMI Tag in the factory?

In fact, HMI Tag is widely used in most automation lines, from simple stages to complex production systems. Some typical examples:

- Automatic packaging line: Tag manages motor signals, position sensors, product detection sensors. Displays the quantity of finished products, packaging speed, conveyor status.

- Tank and feeding system: Tag records liquid level, pump flow, tank temperature. Monitor tank overflow or empty warning, automatically control valve opening/closing.

- Electronic component assembly line: Tag connects assembly robots, checks product errors. Collects production data to calculate efficiency (OEE), traceability.

- Connect multiple multi-brand PLCs: Factories often use PLC XINJE, Mitsubishi, Siemens, … Tag plays a role in connecting signals between HMI and these PLCs, ensuring data consistency.

Conclusion

In modern automation systems, HMI Tag is a key factor in connecting, monitoring and controlling the production line accurately and safely.

Understanding HMI Tag Definition, classifying and managing tags scientifically not only helps engineers program more easily but also optimizes operating performance, minimizes errors and saves maintenance costs.

If your business is operating a factory with automation equipment such as PLC, HMI, sensors, focus on building a logical, clear tag system from the beginning to ensure stability and scalability in the future. Contact XINJE now for advice on suitable HMI & PLC solutions, optimize production lines and improve factory productivity!