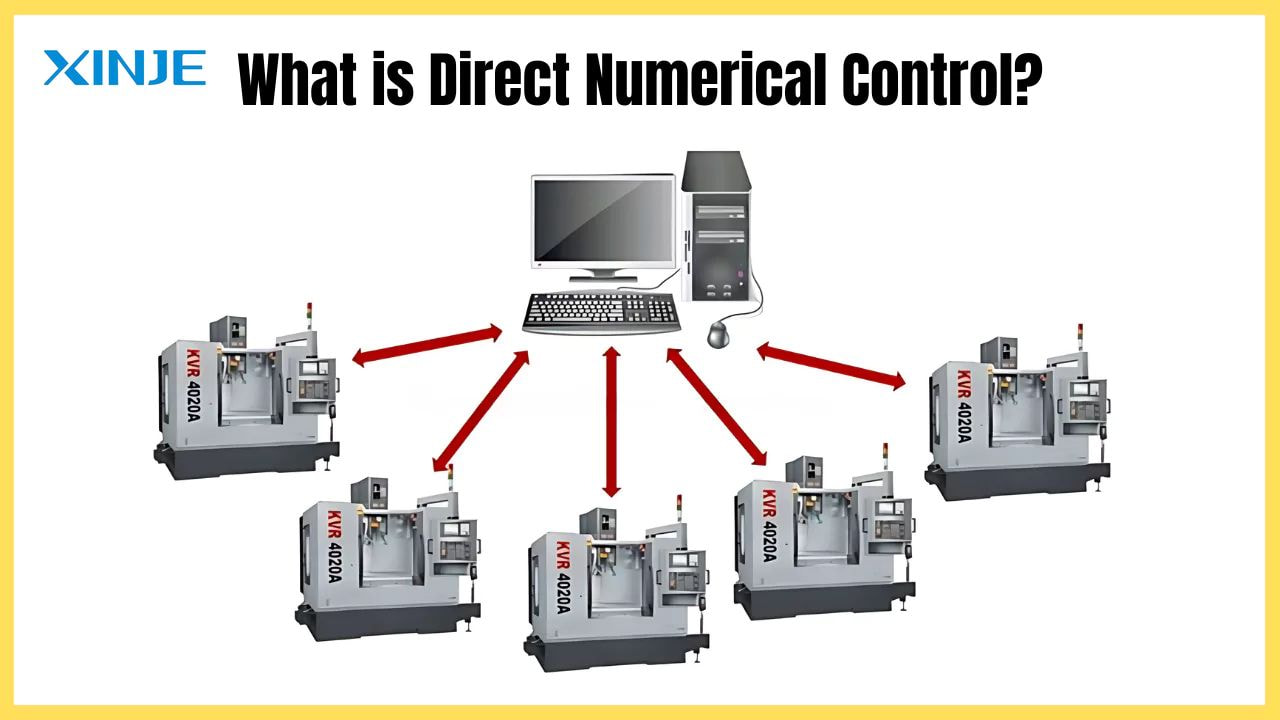

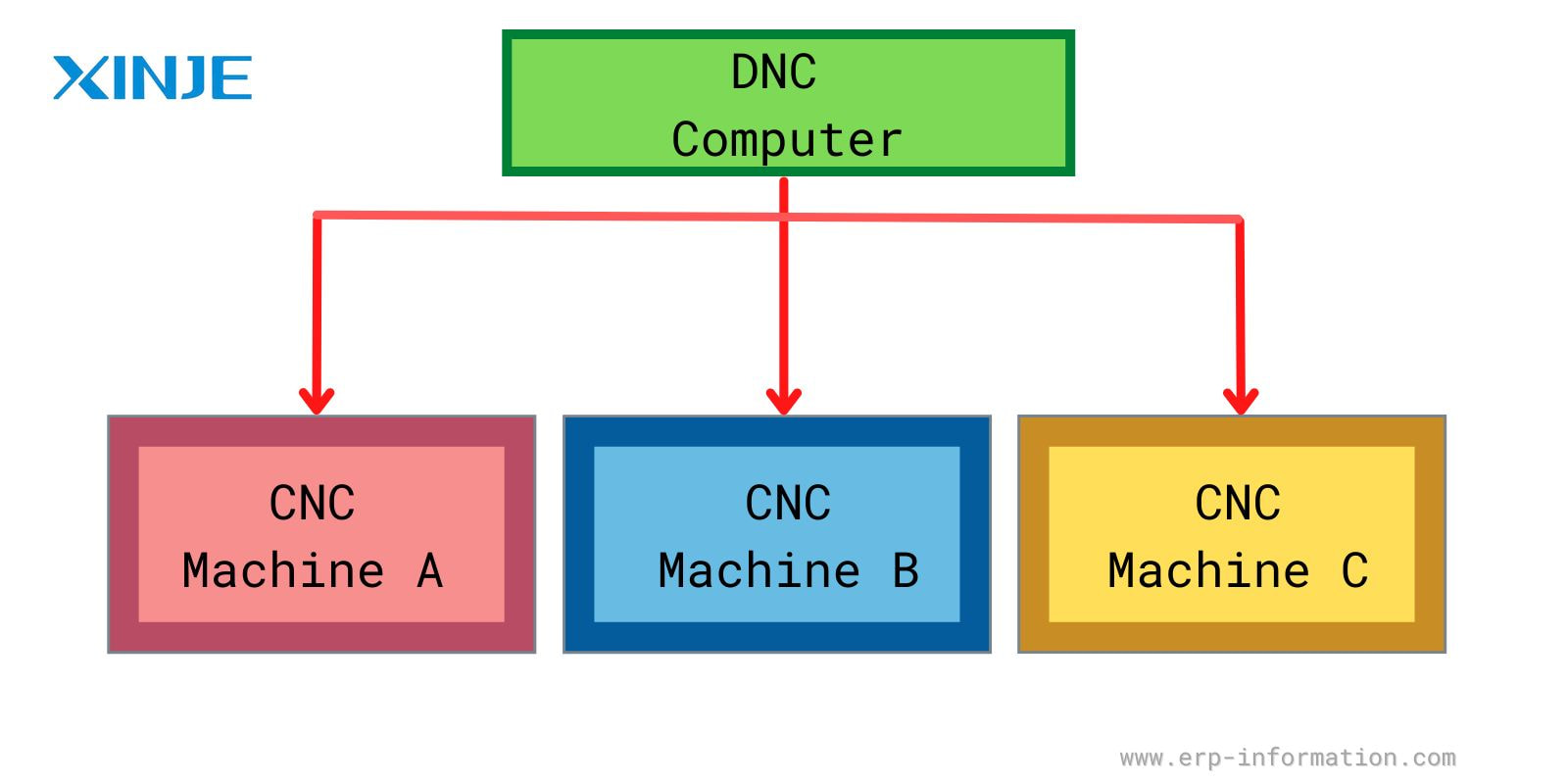

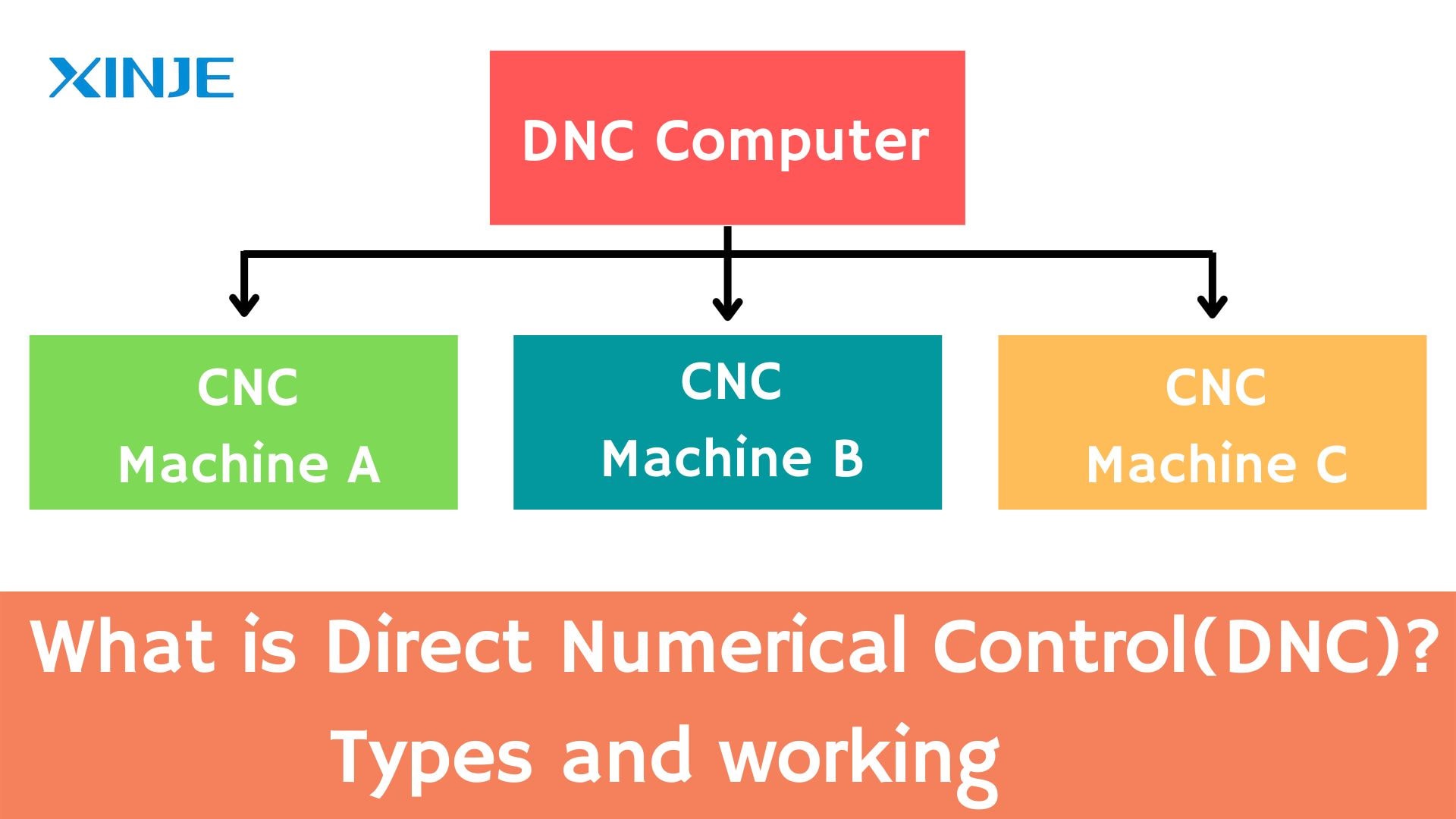

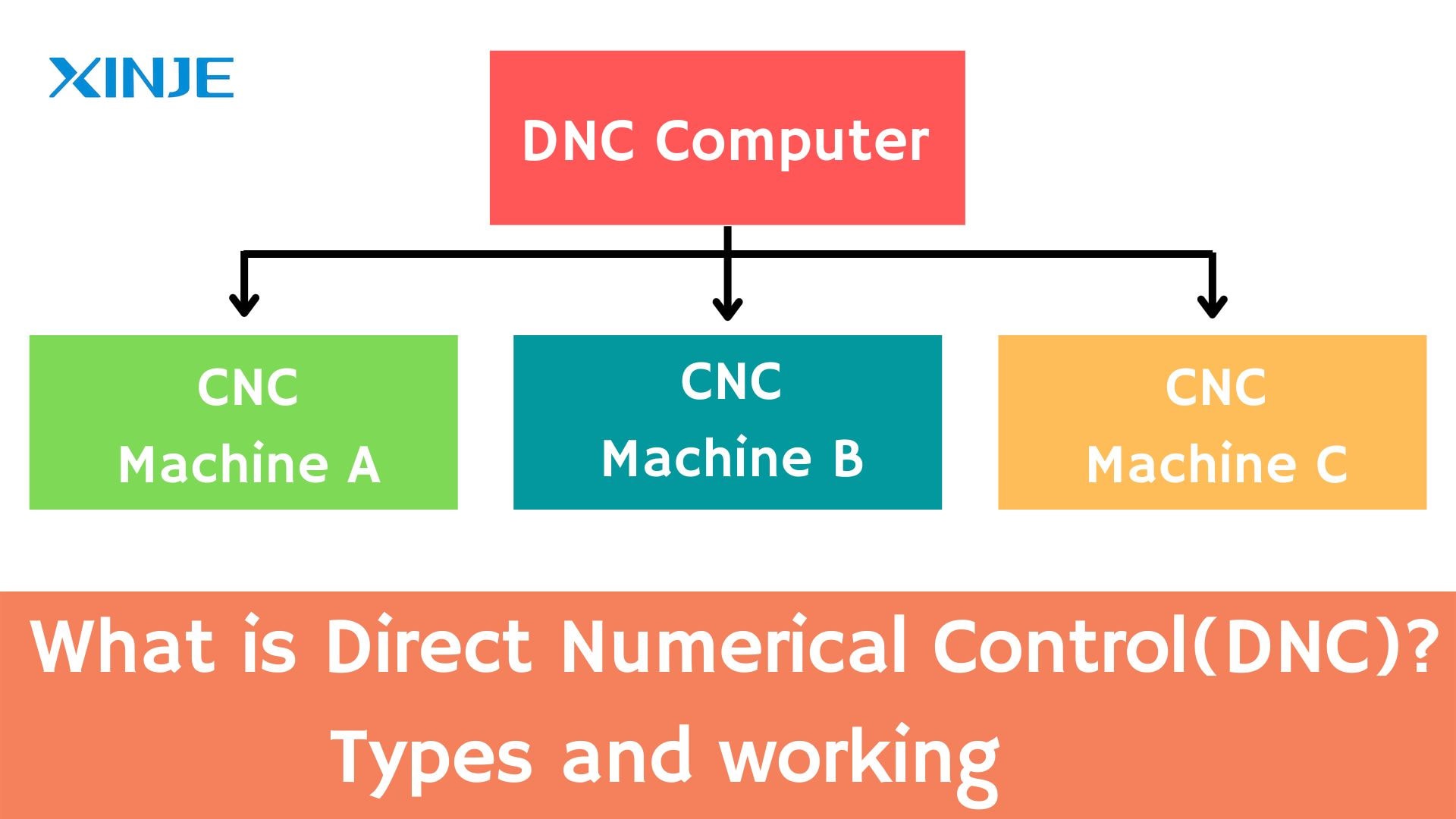

Intro: Direct Numerical Control (DNC) is a centralized system that controls multiple machine tools through a single computer. This system allows seamless communication between machines and streamlines operations, making it an essential tool in modern manufacturing industries. DNC eliminates manual input by directly feeding data into machines, ensuring higher precision and efficiency.

what-is-the-direct-numerical-controlDNC is pivotal in enhancing productivity and reducing operational costs in industries like electronics, automotive, and aerospace thrive. Its adoption signifies a shift towards smart manufacturing, aligning with the country’s Industry 4.0 goals.

What are the outstanding advantages of Direct Numerical Control?

Direct Numerical Control (DNC) has revolutionized the manufacturing industry by seamlessly integrating technology and automation. This advanced approach to production management has brought about several key benefits that have made it indispensable for modern manufacturers striving for efficiency and quality. Some of the key features of the DNC include:

- Improved Efficiency: DNC optimizes workflow by enabling machines to operate continuously without manual intervention. This minimizes downtime and maximizes output.

- Enhanced Accuracy: By directly feeding precise data into machines, DNC reduces human errors, leading to consistent and high-quality production.

- Centralized Control: A single computer manages multiple machines, simplifying operations and reducing the complexity of machine management.

- Cost-Effectiveness: Automation through DNC reduces labor costs and material waste, offering significant savings for manufacturers in Malaysia.

- Real-Time Monitoring: DNC systems provide real-time updates on machine performance, enabling quick adjustments and efficient resource allocation.

What is the difference between CNC and DNC?

Although CNC (Computer Numerical Control) and DNC are often confused, they serve distinct purposes in automation:

| Feature | CNC | DNC |

| Control Scope | Control ScopeControls a single machine tool | Controls multiple machines |

| Data Storage | Data stored locally on the machine | Data stored in a central computer |

| Communication | Limited to the machine | Network-based communication |

| Scalability | Not easily scalable | Highly scalable |

In essence, while CNC is suitable for standalone machines, DNC excels in complex, interconnected manufacturing environments.

What components does Direct Numerical Control consist of?

Direct Numerical Control (DNC) systems are sophisticated frameworks that streamline manufacturing processes by connecting multiple machine tools to a single central computer. These systems rely on a combination of essential components that work seamlessly to ensure precision, efficiency, and reliability in industrial operations. The main components of a DNC system include:

- Central Computer: Acts as the command center, storing and transmitting instructions to all connected machines.

- Machine Tools: These are the end devices, such as lathes, mills, or drilling machines, controlled by the DNC system.

- Communication Network: Facilitates data transfer between the central computer and machine tools using wired or wireless connections.

- Software Interface: Provides a user-friendly platform for operators to monitor and control the system.

- Data Transmission Devices: Ensure seamless and accurate transfer of instructions to the machines.

What are the most popular types of Direct Numerical Control today?

Direct Numerical Control (DNC) has evolved over the years to meet the diverse needs of modern manufacturing industries. Today, many different types of DNC systems are widely used, each with its own advantages depending on the specific operating requirements, some popular types on the market are: Serial DNC, Distributed DNC, Wireless DNC

- Serial DNC: Uses serial communication to connect the central computer with machine tools. It is simple and cost-effective but may have slower data transfer rates.

- Distributed DNC: A decentralized version where multiple computers are used to control specific groups of machines. This setup improves reliability and reduces the load on the central computer.

- Wireless DNC: Eliminates the need for physical connections by utilizing wireless technology. It is gaining popularity in Malaysia due to its flexibility and ease of installation.

What are the applications of Direct Numerical Control?

Direct Numerical Control (DNC) systems play a pivotal role in modern manufacturing by improving accuracy, efficiency, and scalability across a wide range of industries. Their versatility makes them indispensable in many industrial sectors such as:

- Automotive Manufacturing: DNC ensures precision in processes like machining and assembly, crucial for producing high-quality automotive components.

- Aerospace Industry: With stringent requirements for accuracy, DNC supports the production of complex parts for aircraft and spacecraft.

- Electronics Sector: In the growing electronics industry, DNC enhances the production of circuit boards and semiconductor devices.

- Tool and Die-making: DNC facilitates the creation of intricate molds and dies, meeting the demands of Malaysia’s manufacturing sector.

- General Manufacturing: From textiles to consumer goods, DNC improves efficiency and reduces costs across diverse industries.

Conclusion

Direct Numerical Control (DNC) is transforming Malaysia’s industrial landscape by driving efficiency, precision, and scalability. Its integration into various sectors highlights its importance in achieving the goals of Industry 4.0. By understanding the advantages, components, and applications of DNC, businesses can tap into its potential to remain competitive in a rapidly evolving market.

As the trend of industrial automation continues its journey towards smart manufacturing, the adoption of technologies such as DNC will play a key role in shaping a more innovative and sustainable future.