In the automation industry, controlling the on/off time of equipment is an important factor to ensure smooth and accurate operation. Cam Timer is an optimal solution, helping to control time automatically, stably and reliably. So what is Cam Timer? How does it work and what are its applications in the era of Industry 4.0? Let’s explore the details with XINJE in the article below!

What is a Cam Timer?

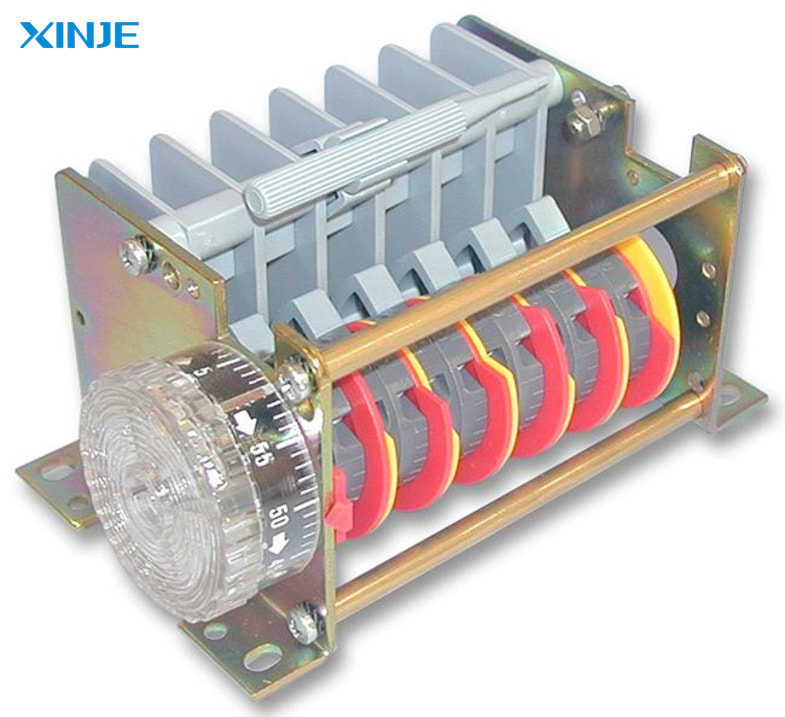

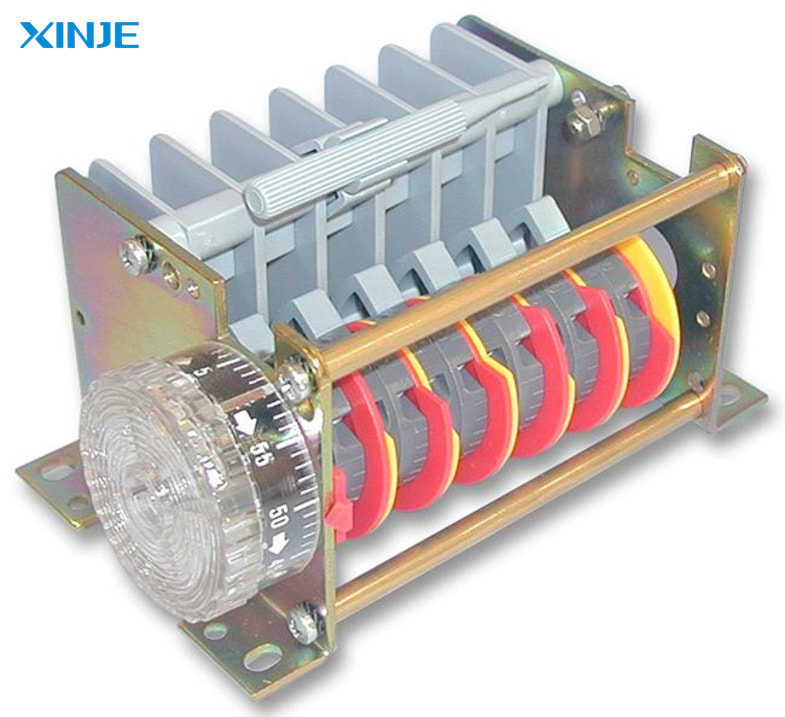

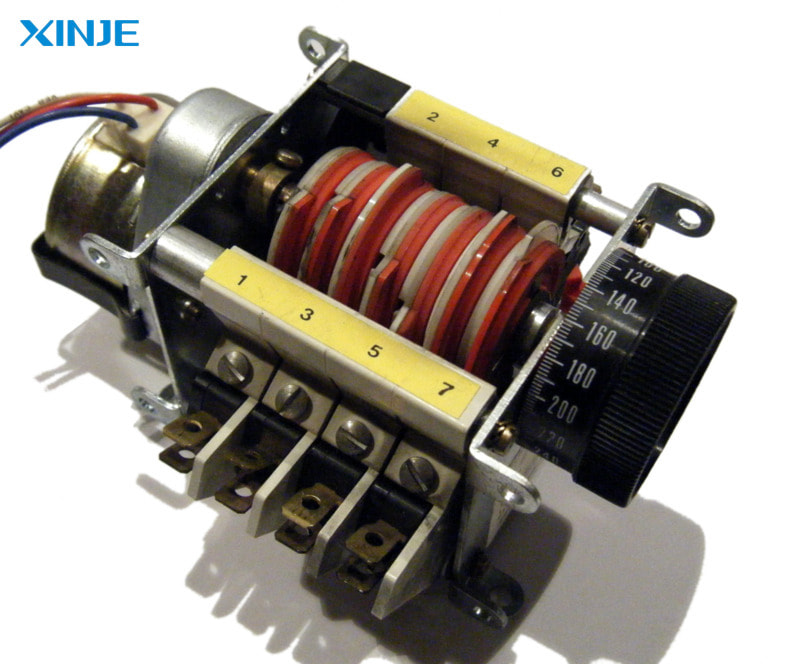

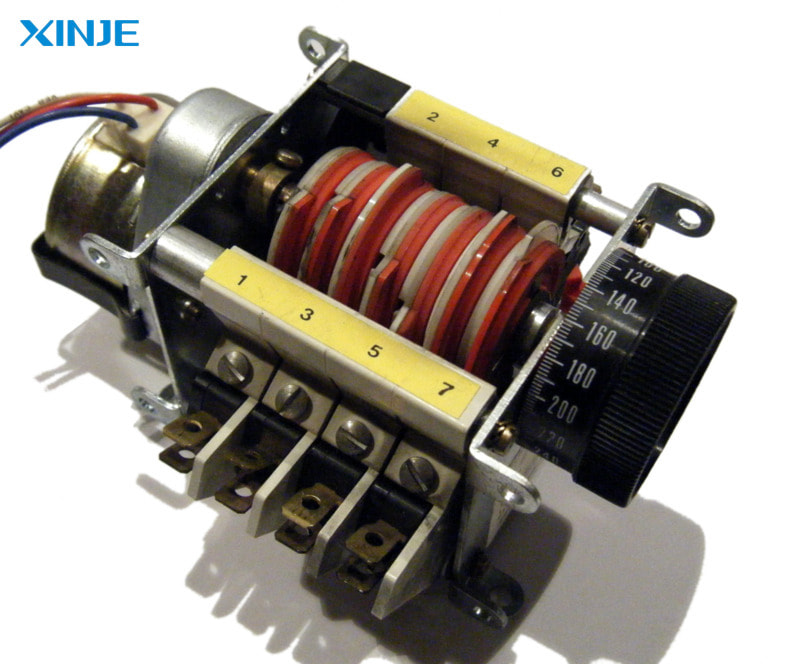

A Cam Timer is an electromechanical device that uses a rotating cam mechanism to control electrical devices’ on/off time in an automation system. When the cam rotates to a certain position, it will activate or deactivate electrical contacts, helping to coordinate the operation of motors, conveyors, packaging machines and many other devices.

Cam Timers are durable, operate stably and are often used in systems that require precise timing.

What is the main structure of Cam Timer?

The Cam Timer is an important device in the automation system, with a structure consisting of many parts working together to ensure accurate operation according to the preset time. Cam timer consists of the following 5 main parts:

- Cam Shaft: This is an important part that helps create cyclic movements to control electrical contact’s on/off time.

- Drive Mechanism: This is the component that helps provide energy to rotate the camshaft at a stable speed. Depending on the type of Cam Timer, the drive system can be an electric motor, gear set, belt or chain system.

- Cam Discs: The cam disc is the part that determines when and how long the electrical contacts are activated. The number of cam discs on the shaft will correspond to the number of control channels of the Cam Timer.

- Time Adjustment Mechanism: Allows users to set and change the on/off time of the Cam Timer.

- Protective housing: Helps protect internal components from dust, moisture, and mechanical impact. The housing is usually made of metal or hard plastic, has anti-vibration and waterproof capabilities according to IP standards to ensure stable operation of the device in harsh industrial environments.

How many types of cam timers are there?

Cam Timers can be classified based on many different criteria, including control mechanisms and practical applications. Below are the common types:

Classification by control mechanism

- Mechanical Cam Timer: The mechanical Cam Timer operates based on the rotation of a camshaft attached to electrical contacts. When the cam rotates to a certain position, it will act on the contacts to close or break the electrical circuit.

- Electronic Timer Cam: An Electronic Timer Cam uses an electric circuit and microcontroller to replace a mechanical cam. This device can be programmed to adjust the time flexibly.

Classification by practical application

- Cam Timer used in motor control: This type is used to turn on/off the motor in a certain cycle to optimize operating performance. The device is often used in automatic valve control systems according to time.

- Cam Timer in automatic lighting systems: This type of Timer Cam helps turn on/off lights according to a set schedule, helping to save energy and increase the life of the device. Therefore, they are often used to control street lights, public lighting systems, or applied in agricultural greenhouses to adjust artificial light.

- Cam Timer in production lines: In factories, Timer Cam helps ensure that production stages take place in the correct order and at a predetermined time.

Choosing the right Cam Timer helps optimize production processes, save energy and increase the operating efficiency of automation systems.

Why use Cam Timer in automation system?

- High accuracy: For electronic Cam Timer, the time is set through software or control panel, helping to optimize accuracy up to milliseconds.

- Stable and durable operation: With a sturdy mechanical design and less dependence on electronic microchips, Cam Timer can operate stably for a long time without being affected by electromagnetic interference or environmental changes.

- Ability to control multiple devices synchronously: Cam Timer can control multiple output channels thanks to the number of cam discs on the shaft. This makes it easy to synchronize the operation of multiple devices in a system, such as conveyor belts, packaging systems or industrial printers.

- Saving investment costs: For applications that require fixed time control and do not require complex programming, Cam Timer is an optimal choice to help businesses save costs while still ensuring operational efficiency.

- Easy to adjust and maintain: Cam Timer has a simple mechanical structure, so the maintenance and repair process is also easier than complex electronic controllers.

With advantages such as high precision, stable operation, the ability to control multiple devices synchronously and easy maintenance, Cam Timer is an important device in industrial automation systems.

Conclusion

In the era of Industry 4.0, when manufacturing systems are increasingly moving towards automation and smart connectivity, Cam Timer still plays an important role thanks to its ability to control time accurately, operate stably and be easily integrated into many production lines.

Combining Cam Timer with modern technology solutions can help businesses improve performance, optimize production processes and ensure flexibility in the digital age.