Advanced Plant Management System (APMS) is an advanced plant management system designed to optimize production line operations, reduce operating costs and improve efficiency. APMS combines information technology and automation systems to provide effective monitoring solutions, controlling and analyzing production processes. So do you wonder why Advanced Plant Management System is used by so many people? Read the following article of XINJE for more details.

What is the main function of Advanced Plant Management System (APMS)?

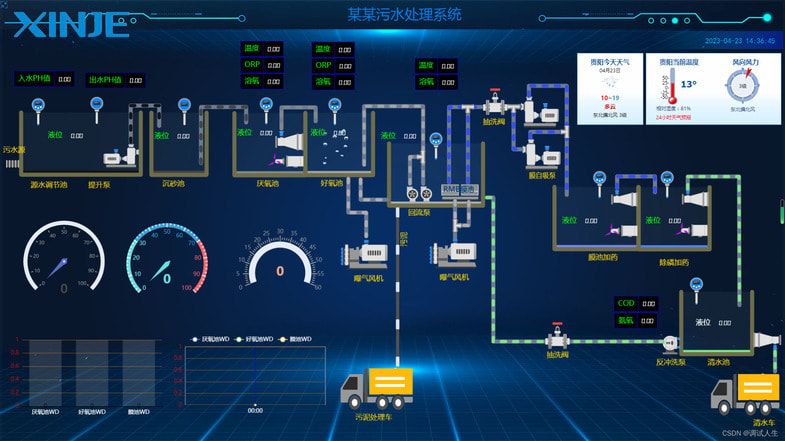

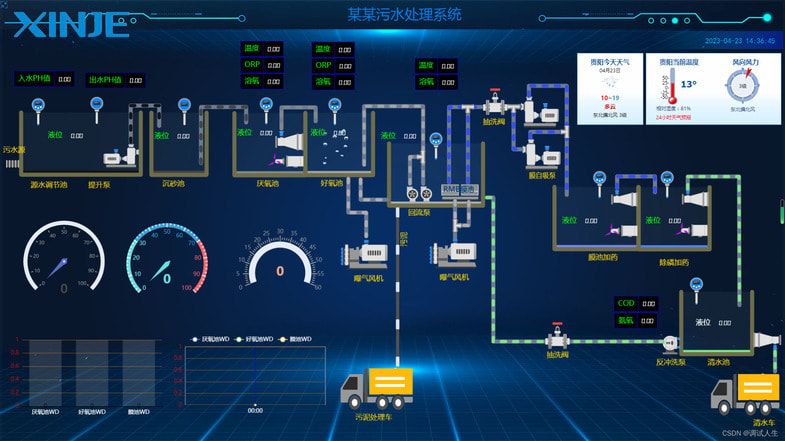

- Real-time monitoring: Provides detailed information on the operating status of equipment and production processes, helping managers detect problems quickly.

- Optimize production processes: Analyze data from sensors and control devices, helping to optimize the performance of each stage in production, reduce waste and save energy.

- Smart maintenance management: APMS integrates with maintenance systems to predict and plan equipment maintenance, minimizing downtime.

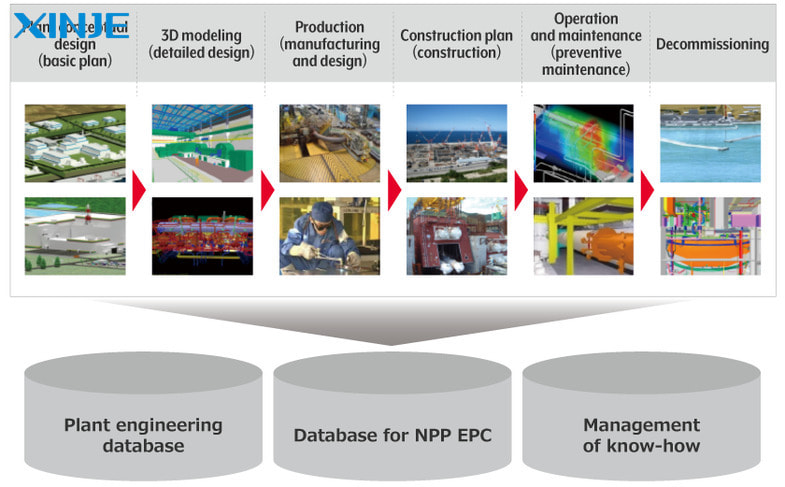

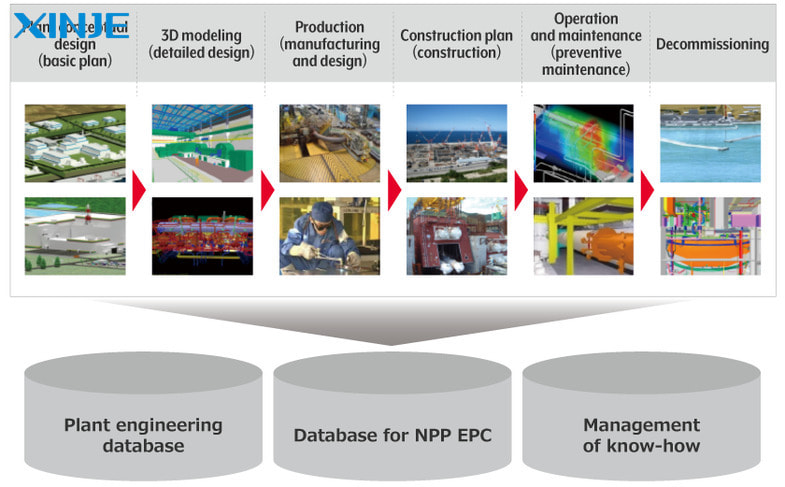

- IoT and AI integration: The system is capable of connecting to IoT devices to collect data from sensors and use AI to analyze and make automatic decisions, helping to optimize production processes and minimize errors.

- Quality management: Monitor and ensure product quality through indicators and automatic quality checks throughout the production process.

- Analysis and reporting: Provides detailed and visual reports on production performance, labor productivity, costs, and other factors, helping managers make more accurate decisions.

APMS is a powerful tool that helps factories and businesses in the manufacturing industry improve their competitiveness through the use of advanced technology to optimize processes and improve overall performance.

Why use an Advanced Plant Management System in manufacturing?

- Increase production efficiency: APMS helps monitor production processes continuously and accurately, ensuring that each stage in the production line runs smoothly. Thanks to the ability to optimize processes and minimize downtime, production efficiency is improved.

- Reduce operating costs: The system helps reduce waste and optimize the use of resources (such as energy, raw materials and labor). Analytical information from APMS helps managers identify costly factors, thereby providing improvement measures.

- Improve product quality: With the ability to monitor quality in real time, APMS helps detect quality problems early and ensure that the production process is always up to standard. Quality indicators can be adjusted immediately to avoid errors or defective products.

- Minimize errors and risks: The system provides detailed reports and data analysis, helping to minimize errors caused by human error. Decisions based on data from APMS are often more accurate, minimizing the risk of risks in production.

- Proactive management and maintenance: APMS integrates predictive tools to plan equipment maintenance, helping to minimize downtime due to unexpected incidents. Timely maintenance and optimized maintenance cycles will extend the life of equipment, reducing repair costs.

In short, APMS not only helps improve production efficiency but also brings operational sustainability, enhances competitiveness and the ability to meet market needs.

Notes when using Advanced Plant Management System

When using Advanced Plant Management System (APMS), there are some important notes to consider to ensure maximum efficiency and avoid problems arising during the implementation and operation of the system

- Ensure compatibility with existing systems: Integrating legacy systems with APMS can be difficult without a clear plan and appropriate conversion tools.

- Training and staff development: Ensure that employees are properly trained on how to use the system to maximize its features, minimize errors and increase productivity.

- Evaluate implementation and maintenance costs: APMS implementation requires an initial investment of USD 30,000-50,000. These costs need to be carefully evaluated and compared with the long-term benefits that the system brings to ensure that investing in APMS is reasonable and economically effective.

- Continuous monitoring and evaluation of performance: To ensure that the APMS delivers the expected results, it is necessary to establish key performance indicators (KPIs) related to production performance, cost savings, product quality, and maintenance.

- Ensure data security: Businesses need to apply data security measures such as encryption, user authentication, and monitoring for unusual activities to protect the system from cyber attacks or data loss risks.

Applications of Advanced Plant Management System (APMS)

Advanced Plant Management System (APMS) has wide applications in many industries such as chemical, food processing, automobile manufacturing, oil and gas, etc. to optimize production processes, quality management and equipment maintenance.

The system helps monitor and control production stages from start to finish, ensuring optimal performance and minimizing waste. In addition, it also helps monitor and ensure product quality throughout the production process, from input materials to finished products.

With the ability to integrate advanced technologies such as Internet of Things (IoT) and big data analysis, APMS helps businesses improve performance, reduce operating costs and enhance competitiveness in the market.

Conclusion

In the era of Industry 4.0, Advanced Plant Management System (APMS) is not only a production support tool but also an important platform to help businesses adapt and develop sustainably. APMS helps factories shift from manual management to automated management, helping to improve accuracy in each stage, minimize errors and optimize the production process.

The application of advanced technologies such as the Internet of Things (IoT) and artificial intelligence (AI) not only improves performance but also creates the ability to predict and handle problems as they arise. APMS helps businesses not only maintain but also overcome major challenges in the modern production environment, while creating a solid competitive advantage in the context of globalization and rapid market changes.