Advanced Physical Layer (APL) is an advanced communications technology specifically designed for industrial applications in process automation. APL is a communications protocol built on the industrial Ethernet standard, providing robust, high-speed, and reliable data transmission in harsh industrial environments. Join XINJE to explore the following article for more details.

Key Features of Advanced Physical Layer (APL)

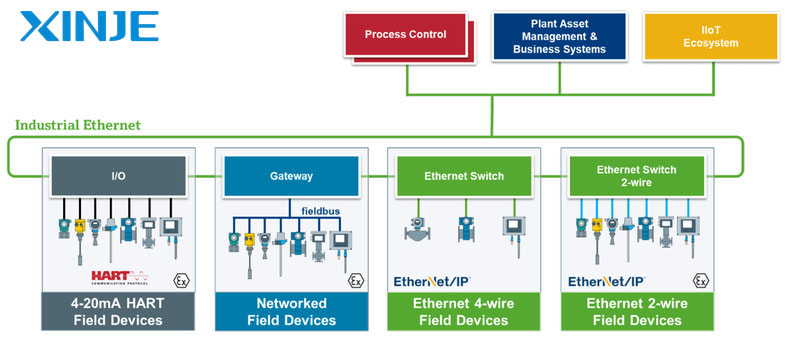

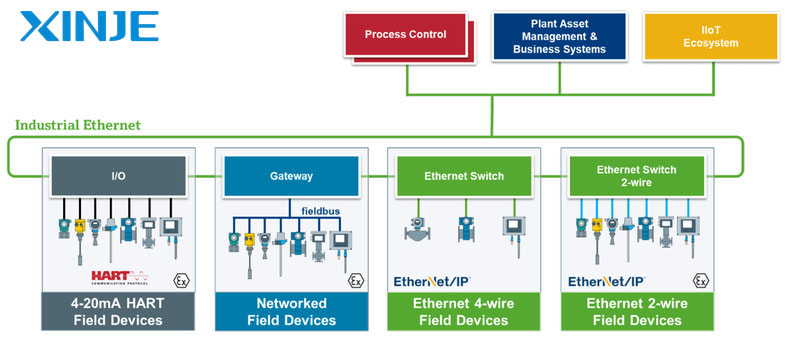

- Integration with Industrial Ethernet: APL enables the use of Ethernet in industrial environments that have traditionally used only traditional fieldbus protocols. Provides high-speed data transmission (up to 10 Mbps).

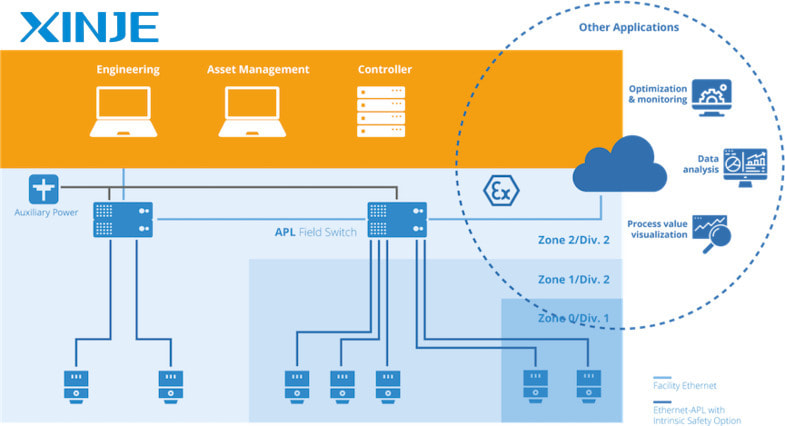

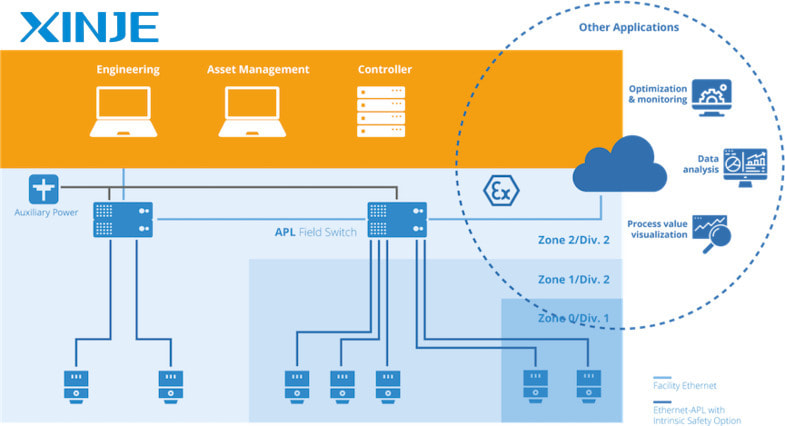

- Power over Ethernet (PoE): A single Ethernet cable is required to provide both power and data transmission, reducing installation and maintenance costs.

- Long-range data transmission: Supports stable data transmission over distances of up to 1000m (compared to the typical 100m limit of standard Ethernet)

- Stable operation in harsh environments: APL is designed to operate in explosive environments or areas requiring high safety requirements such as Zone 0/Zone 1 in the oil and gas and chemical industries.

- High compatibility: APL is an open standard, compatible with industrial protocols such as PROFINET, EtherNet/IP, and OPC UA.

Why use Advanced Physical Layer Technology in manufacturing systems?

Advanced Physical Layer (APL) is not only an advanced technology but also brings outstanding values to the industry. As factories and businesses move towards intelligent automation and process optimization, APL becomes the key to unlocking great potential.

Below are the specific benefits that APL brings to modern industry.

- Meet the needs of complex systems: APL provides significantly higher bandwidth and faster data transmission speeds than older technologies such as CAN or LIN. This allows for the rapid and efficient transmission of large amounts of data from complex sensors such as high-resolution cameras, radar, and lidar.

- Cost savings: APL can transmit data over longer distances with fewer wires than older technologies. This reduces material costs, vehicle weight, and assembly complexity.

- Good anti-interference ability: This technology uses advanced noise reduction techniques to ensure data integrity and minimize the risk of transmission errors.

- Increased performance and reliability: Ensures accurate and fast data transmission, even in difficult environmental conditions.

- Easy to upgrade: APL systems can be easily upgraded when needed, without changing the entire system structure.

What are the considerations when using Advanced Physical Layer Technology?

Although Advanced Physical Layer Technology (APL) brings many outstanding benefits in industrial connectivity and automation, to maximize the effectiveness of this technology, it is necessary to pay attention to some important factors during deployment and operation.

- Ensure device compatibility: Make sure that devices support the Ethernet-APL standard to avoid connection problems. If necessary, upgrade old devices to synchronize with APL technology.

- Design the appropriate network system: Use cables and connectors that comply with the Ethernet-APL standard to ensure stable data transmission, especially in harsh industrial environments.

- Meet safety and security requirements: Choose devices with good electrical isolation to ensure safety when operating in hazardous areas. Use security measures such as firewalls, data encryption, and access control to avoid the risk of cyber attacks.

- Regular maintenance and inspection: Ensure that all cable connections and equipment in the APL system are in good working order, with no signs of wear or physical damage.

- Choose a reliable supplier: Choose equipment and solutions from reputable suppliers, ensuring quality and good after-sales service. You can refer to XINJE for the best choice.

What are the applications of Advanced Physical Layer Technology?

Thanks to its easy integration with industrial communication protocols and its superior speed, security, and fault tolerance, APL has been widely applied in many fields.

Smart factory management and monitoring

- Connect field devices to the central management system.

- Access real-time data to optimize production processes.

- Increase remote monitoring capabilities and support predictive maintenance.

Oil, gas, and chemical industries

- Stable operation in harsh environments, such as high temperatures or areas with explosive hazards.

- Accurate transmission of data from remote sensors and measuring devices to the control center.

- Minimize risks thanks to its electrical isolation and powerful signal processing capabilities.

Energy management systems

- Flexibly connect to energy measuring sensors and transmission devices.

- Optimize energy usage, reduce operating costs.

- Respond quickly to changing energy supply and demand requirements.

Process automation in the food and beverage industry

- Increase accuracy in controlling temperature, humidity, and other critical parameters.

- Ensure food quality and safety through automated monitoring and inspection.

- Meet hygiene standards and ease maintenance in manufacturing environments.

Transportation

- Connect devices such as traffic sensors, surveillance cameras, and traffic lights.

- Ensure fast and accurate data transmission to optimize traffic flows.

- Support real-time data analysis to reduce accidents and congestion.

Conclusion

Advanced Physical Layer (APL) technology is not only a step forward in industrial communications, but also the foundation for future-ready automation systems. Seamless integration with industrial Ethernet protocols, stable operation in hazardous environments, and optimized cost and performance make APL an indispensable choice in many fields.

From improving plant management, enhancing safety in the oil and gas industry, to optimizing processes in the food and beverage industry, APL has proven its versatility and value. As businesses increasingly adopt smart technology, APL will certainly play a central role in shaping the future of industrial connectivity.