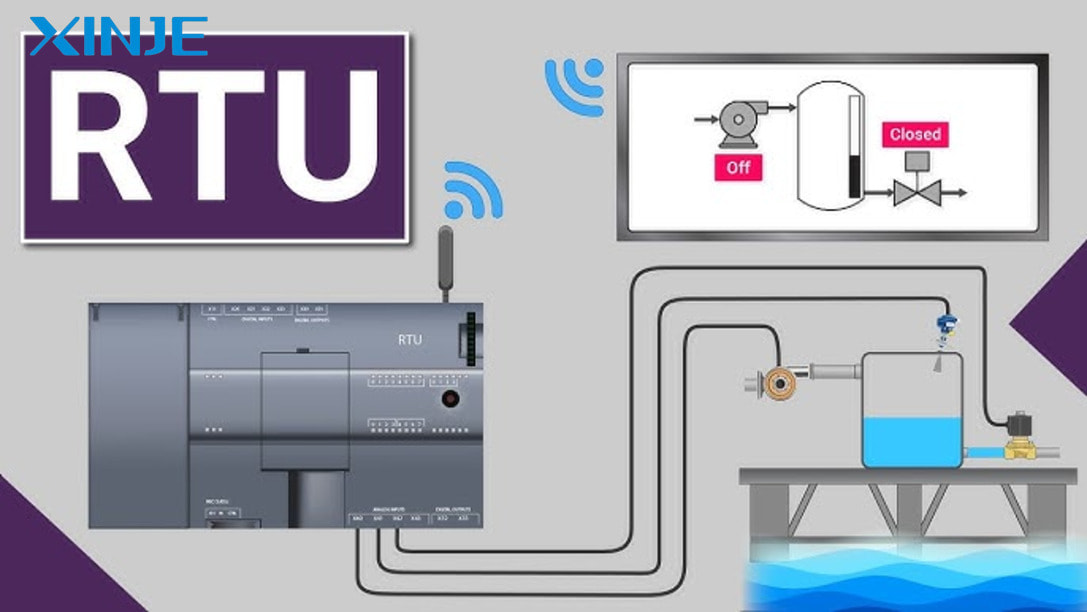

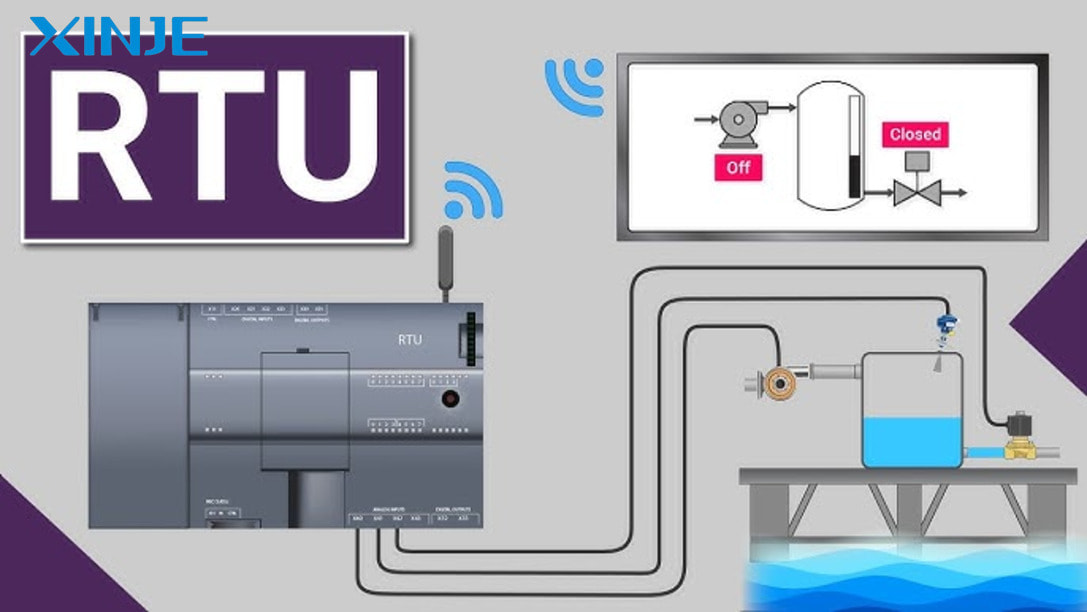

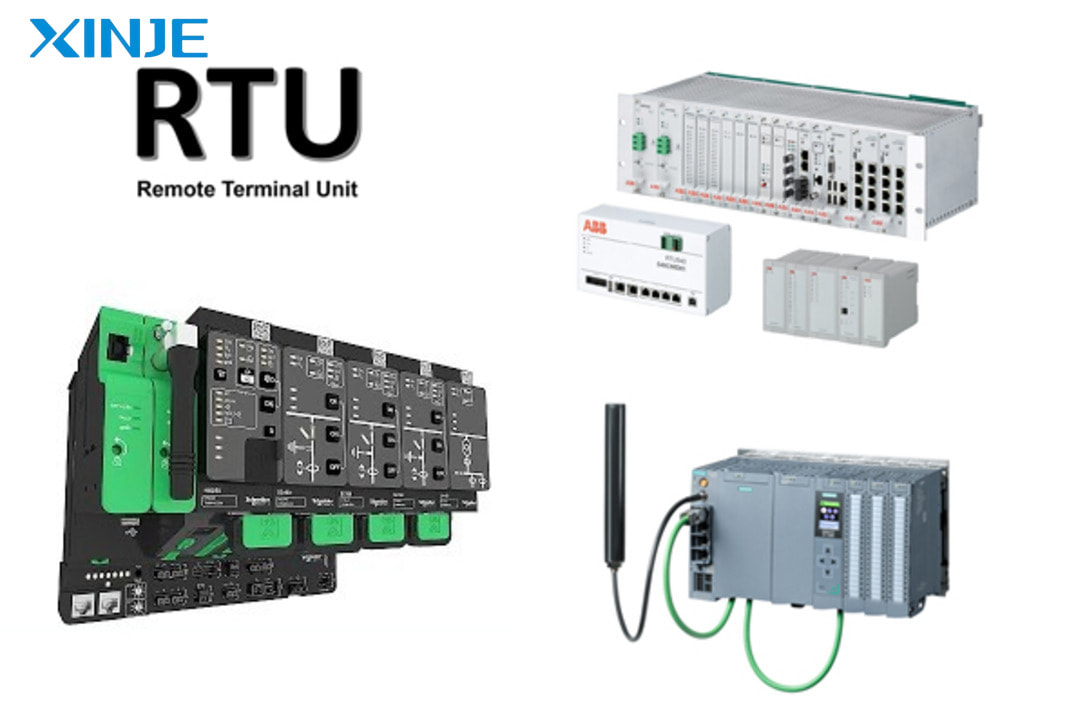

RTU also known as a remote terminal device, has a specialized function to collect, monitor, and control devices from a fairly long distance. RTU is composed of basic components such as CPU, power supply, physical I/O…

Thanks to its ability to monitor and operate stably, remote terminal devices are widely used in many fields from life to production. It is most easily seen in smart grid devices, oil and gas production areas, and wastewater treatment…

Let’s follow the article to the end to understand more about the functions, components, advantages, and disadvantages of this RTU device.

What outstanding functions does RTU have?

The RTU remote terminal unit has several outstanding functions besides controlling the automation system such as:

- Data monitoring and collection: RTU collects and monitors data from sensors and gauges. These data include temperature, liquid level, speed, device location, security status, etc.

- Data transmission: RTU compiles information from field devices and transmits it to the central system for efficient process management and control.

- Remote management and control: RTU supports real-time remote monitoring and control of devices, helping to increase productivity, reduce downtime, and optimize operating costs for the entire system.

- Wide application: The device is applied with many advanced technologies such as microprocessors. RTU has been trusted and widely used in many industrial and commercial fields such as power generation, water and gas distribution, and building automation.

What is the RTU commonly used for?

Thanks to their efficient data collection, management, and monitoring features, RTU terminals have been trusted and applied in many industrial fields such as:

- Smart grid: RTU will support monitoring and control of electricity distribution to each area, managing electricity flow to households and businesses in real-time with the exact required voltage level.

- Oil and gas production: RTU supports monitoring of pipelines, tank levels, and wellheads, facilitating more efficient oil and gas production processes.

- Water and wastewater treatment: RTU helps monitor and control water and wastewater treatment plants’ pH, flow rate, or chemical dosage levels.

- Alternative energy systems: RTU controls and monitors systems such as solar panels, wind turbines, or hydroelectric plants, to ensure stable performance and support warnings when necessary.

- Remote Measurement System: RTU enables remote monitoring and control of equipment such as offshore oil rigs and weather stations. Provides optimal convenience and ensures maximum safety for operators

What are the advantages and disadvantages of RTU?

Advantages

Some notable advantages of the terminal unit (RTU) include:

- Low power consumption: RTU is very suitable for remote locations where the power supply is limited, prioritizing data transmission only when needed, to help save energy.

- Durable operation in harsh environments: The device is highly durable because it can withstand harsh weather conditions with many difficult industrial environmental conditions such as mountainous areas or remote areas.

- Automatic data storage: data from I/O devices can be stored with time and date stamps. At the same time, the stored data can be transmitted when needed, even in unstable communication conditions.

- Highly customizable: RTU is highly flexible and easily expanded with communication modules, I/O, data storage, batteries, and backup power.

Disadvantages

Along with the outstanding advantages, RTU still has certain disadvantages that users need to note:

- High installation cost: the cost of installing and maintaining the RTU can be expensive, with the average price for a full RTU device falling around $1,100.

- Old technology: Some RTU devices may use outdated technology, leading to slower processing speeds than other modern systems, you need to consider carefully to choose the RTU device that suits your needs.

- Limited processing power: It is easy to see that RTU is not as powerful as PLC in terms of data processing and storage, causing limitations for some high-demand applications.

What are the basic components of the RTU device?

A basic RTU device is usually made up of components such as a central processor, power supply, communication port, and physical I/O.

- Central processor (CPU): This part will support the processing of main data with programming capabilities similar to PLC, using a 32-bit microprocessor or through a basic web interface.

- Power source: Most will use the grid, with a backup battery to maintain operation in remote locations or in case of power failure.

- Communication port: This port helps connect the RTU to the SCADA system through protocols such as Ethernet, RS-232, or Modbus.

- Physical I/O: Includes digital and analog input/output modules, used to collect data and send commands to field devices.

How are RTU and SCADA different?

| RTU | SCADA |

| RTU is a device that collects data from sensors and field devices and then performs basic control steps. | SCADA is a specialized monitoring software for controlling and analyzing data from RTUs and other devices. |

| The main function is to collect data and execute control commands at the scene. | The main function is to process and display data, popular in monitoring, alarming, and decision-making. |

| Affordable price, mainly hardware | Integrating many complex features so the price is higher. |

| Made up of hardware components and therefore does not integrate with a human user interface (HMI) | Software components are multiple pieces of software with a human-machine interface (HMI) and provide visual information. |

| Connected to SCADA via communication protocols such as Modbus, DNP3, etc. | Can communicate with RTU and store, and process data collected from field devices specifically and accurately. |