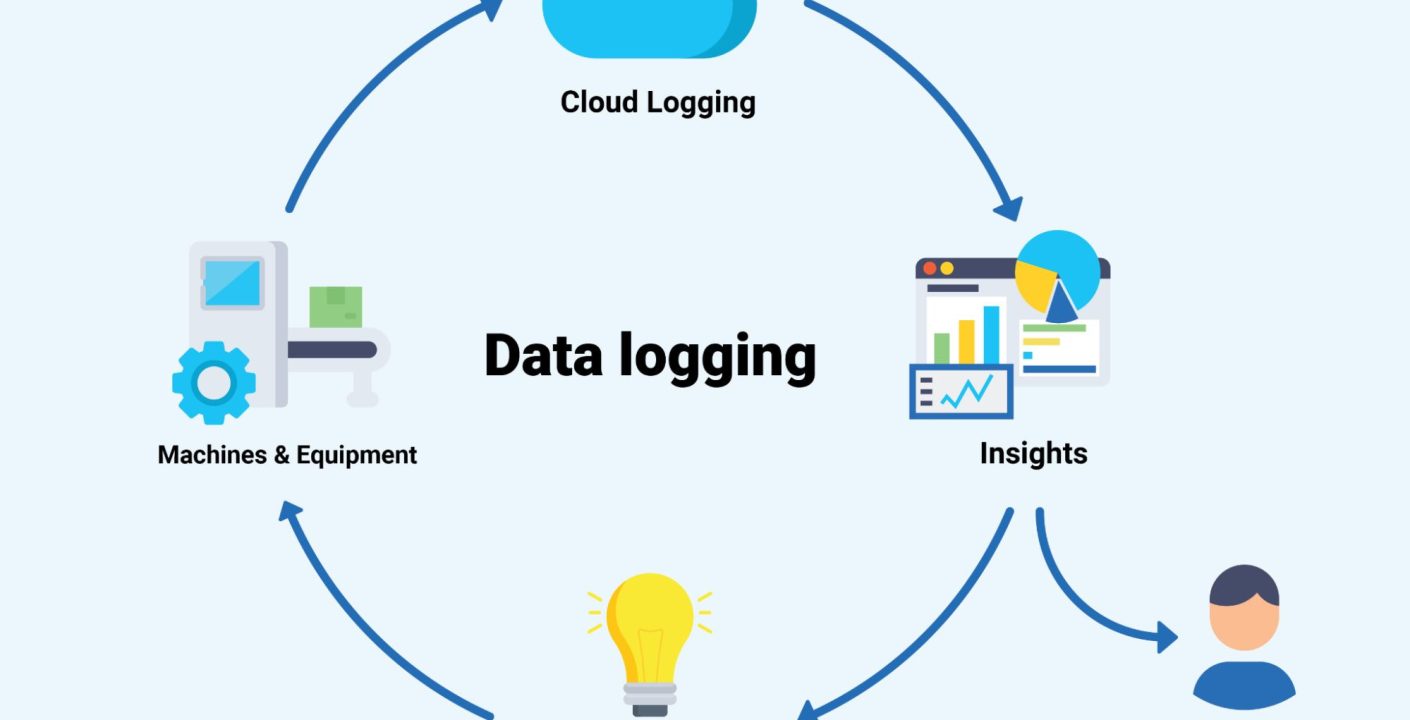

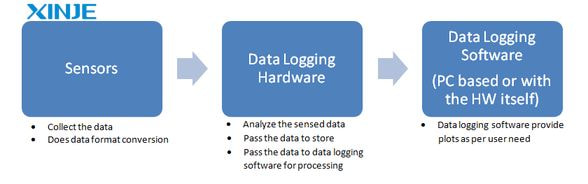

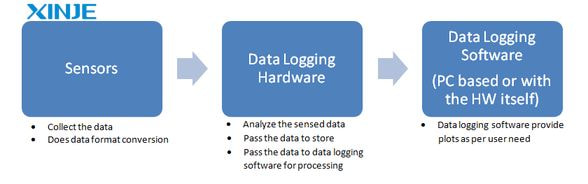

What is Data Logging? Data logging refers to the automatic process of collecting, storing, and managing data over time. In the context of HMI systems, data logging captures real-time values from sensors, machines, or control systems and records them for future analysis.

Whether it’s tracking temperature fluctuations in a cold storage warehouse or monitoring machine cycles in a production line, data logging ensures that every key variable is recorded. It provides the critical visibility necessary for proactive maintenance, process optimization, and regulatory compliance. At its core, data logging allows industries to move from reactive decision-making to predictive strategies backed by real-time data.

What is the purpose of logging data?

Data logging serves many important functions in an industrial HMI system:

- Process Monitoring and Optimization: By continuously logging data, engineers can track the performance of a machine or process over time.

- Quality Control helps ensure products meet quality standards by collecting critical process data such as temperature, pressure, speed, and cycle time.

- Compliance and Reporting: Since many industries must meet strict regulatory requirements, logged data provides auditable evidence that processes are within required limits.

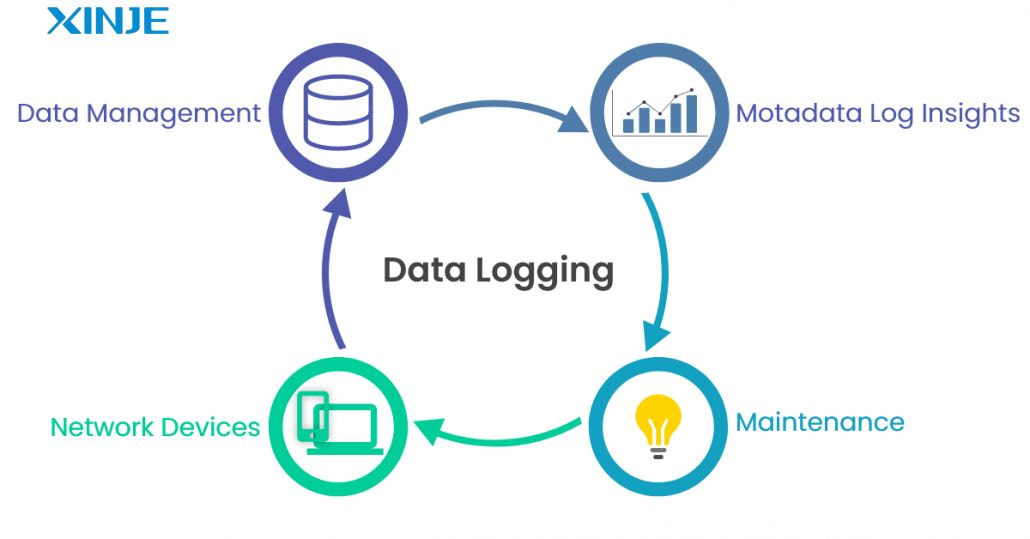

- Predictive Maintenance: By analyzing logged trends, organizations can predict equipment wear or deterioration before a failure occurs, enabling condition-based maintenance and reducing unplanned downtime.

Why is data logging important?

Data logging is not just a feature, but an essential part of modern industrial automation. Here are a few reasons why data logging is important in automation

- Improved system-wide visibility: having a centralized data log ensures an overview of the system’s health. HMI platforms integrate advanced data logging features that make it easy to access real-time insights.

- Support remote monitoring: With the integration of Industry 4.0 and IoT, logged data can be pushed to the cloud, allowing remote access and monitoring from anywhere.

- Support long-term analysis and trends: Short-term metrics only tell part of the story. Data logging allows users to analyze historical trends, seasonal behavior, or performance over time – a key element for continuous improvement initiatives.

- Reduced operating costs: By identifying problems before they escalate, minimizing waste, and optimizing performance, live data logging contributes to savings in maintenance costs, energy usage, and production quality.

Where are data loggers used?

Data loggers are used in almost every industrial and automation field. Some common use cases where HMI integrated data loggers are manufacturing plants, food and beverage industries, or wastewater treatment processes…

- Manufacturing plants: Monitor machine status and performance and record cycle times, machine temperatures, and vibrations.

- The food and beverage industries often use systems to ensure that refrigeration and cooking processes meet HACCP standards. Additionally, the system helps monitor humidity and temperature in warehouses and records production batch records for traceability.

- Pharmaceutical and medical device manufacturing: helps maintain accurate environmental control, records pressure and sterilization cycles, and provides FDA-compliant batch records

- Water and wastewater treatment: Monitor pH, flow rates, chemical dosing, record pump cycles and alarm events, support environmental compliance

- Building automation involves recording HVAC system data to adjust performance, monitoring occupancy sensors and lighting levels, and tracking energy usage.

Conclusion

In short, data logging in systems is more than just recording numbers; it is the foundation of intelligent, responsive, and reliable industrial systems. For businesses using HMI and SCADA systems, implementing robust data logging will deliver a myriad of benefits: operational efficiency, regulatory compliance, real-time monitoring, and predictive maintenance.

As automation continues to evolve, the value of data will only increase. With the right HMI-integrated data logging strategy, manufacturers will gain the insight and control they need to stay competitive in a data-driven industrial world.