Human Machine Interface (HMI) systems play a vital role in efficient plant monitoring and control. One of the most important functions of any HMI is the alarm system. HMI alarms are visual or audible notifications that alert operators to abnormal conditions in the system, such as temperature deviations, equipment failures, or unsafe operating parameters.

These alarms help operators identify problems in real time, allowing for faster response and minimising downtime or damage. However, to ensure these alarms are properly managed and resolved, operators must acknowledge them. That is where alarm acknowledgement functions in HMIs come into play.

This article will examine the key features of HMI alarm systems, their operation, and the actions users should take when encountering HMI alarm acknowledgement prompts.

What are the features of the alarm system?

The HMI alarm system is more than just a simple alarm tool. It is a structured notification and event management system that includes a number of advanced features designed to optimise operator response, improve safety, and support maintenance tasks. Some of the key features include:

- Real-time monitoring: The HMI alarm system continuously monitors a variety of system variables such as temperature, pressure, voltage, and equipment status. When a value exceeds a predefined limit, an alarm is automatically triggered.

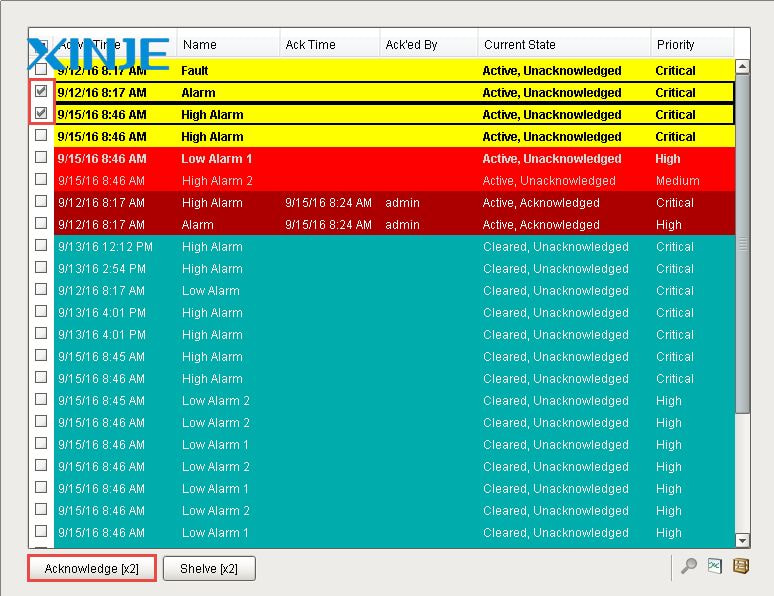

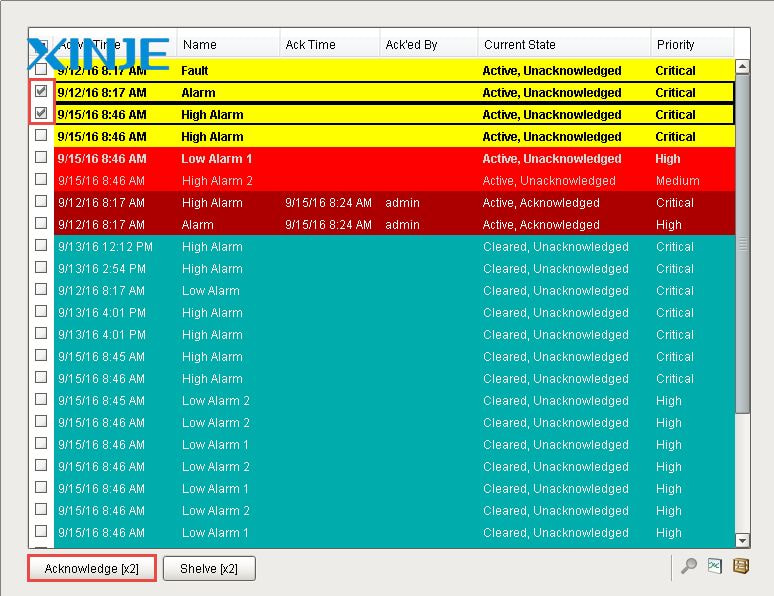

- Alarm priority: Not all alarms have the same level of urgency. The alarm system classifies alarms into different priority levels, such as Critical, Warning, and Information, allowing operators to focus on the most important issues first.

- Alarm logging and history: Each alarm that occurs is logged with a timestamp, description, and acknowledgement status. This alarm history is critical for post-event analysis and troubleshooting.

- Filtering and Suppression of Alarms: Advanced HMIs allow for nuisance alarms to be suppressed or for alarms to be filtered by category, device, or area, allowing for a cleaner, more efficient monitoring screen.

What are the three main parts of an alarm system?

A fully functional alarm system consists of three core components that work together to detect, display, and manage abnormal events

- Alarm Detection: This is the system logic or sensor-based triggering mechanism that determines when a parameter deviates from a set range. For example, a pressure sensor detects an overpressure condition and sends a signal to the HMI.

- Alarm Notification (Display): Once detected, the alarm is displayed on the HMI through various user interfaces such as colour-coded symbols, flashing lights, or audible alarms. The notification includes information such as time, alarm description, and severity.

- Alarm Acknowledgement: This is the final component where the operator responds to the alarm by pressing the “Acknowledge” button. This does not resolve the problem but confirms that the operator is aware of the problem and has initiated corrective actions.

What to do when the HMI acknowledgement alarm appears?

When the HMI alarm acknowledgement screen appears, it is important not to ignore it. Here is a practical guide to what operators should do:

- Identify the severity: Classify whether it is a critical shutdown alert, a safety issue, or a non-emergency alert. High-priority alerts may require immediate action.

- Acknowledge the alert: Click or tap the Acknowledge button to indicate that you are aware of the issue. Some systems may require an operator ID or password to follow up.

- Investigate the root cause: Inspect the actual machine, review sensor data, and evaluate the process. Use the HMI’s diagnostic or trending tools to track the cause of the alert.

- Take corrective action: Depending on the cause, corrective action may include resetting the equipment, stopping the process, replacing the faulty component, or referring to the maintenance team.

- Reporting and Logging: Record the incident in a shift report or maintenance log, especially if the alarm requires significant downtime or repair.

Conclusion

Alarm acknowledgement in HMI systems plays a vital role in industrial automation. It provides operators with real-time awareness of system anomalies, ensures accountability, and facilitates faster resolution of problems. By understanding how HMI alarms work, including their features, structure, and operator response, manufacturing facilities can significantly improve their reliability, safety, and operational efficiency.

A well-designed HMI alarm system is not only a compliance tool but also a powerful ally in proactive and efficient plant maintenance. Whether you are a plant engineer, system integrator, or operator, mastering alarm management is essential to a smart and safe automation environment.