In industrial automation systems, HMI and Modbus are two important components, helping to connect and monitor devices easily and save costs. However, not everyone understands how to configure, program and exploit Modbus effectively on HMI. The following article will guide you on how to use Modbus in HMI from operating principles, configuration steps to security notes, helping your system operate stably and expand more easily.

What is Modbus?

Modbus is an industrial communication protocol developed in 1979, allowing electronic devices such as PLCs, sensors, and inverters to exchange data with each other. Thanks to its simplicity, low cost, and ease of implementation, Modbus has become the most popular communication standard in industrial automation.

In factories, Modbus acts as a “common language” to connect control devices together. This protocol helps transmit measurement data, status, and control signals between PLCs, HMIs, sensors, inverters, etc. quickly and stably. Thanks to that, businesses can easily monitor and optimize production performance.

How to Use Modbus in HMI

To use Modbus in HMI, you need to perform 5 basic steps as follows:

- Hardware connection: Make sure HMI is connected to the device that needs to communicate (PLC, inverter, sensor) via RS-232, RS-485 (Modbus RTU) or Ethernet (Modbus TCP) port.

- Set up communication parameters: Configure the correct Slave address, baud rate, parity bit and other communication parameters so that Master (HMI) and Slave are synchronized.

- Data mapping: In HMI programming software, you need to create data tags corresponding to Modbus registers (Coils, Input, Holding Registers, Discrete Inputs).

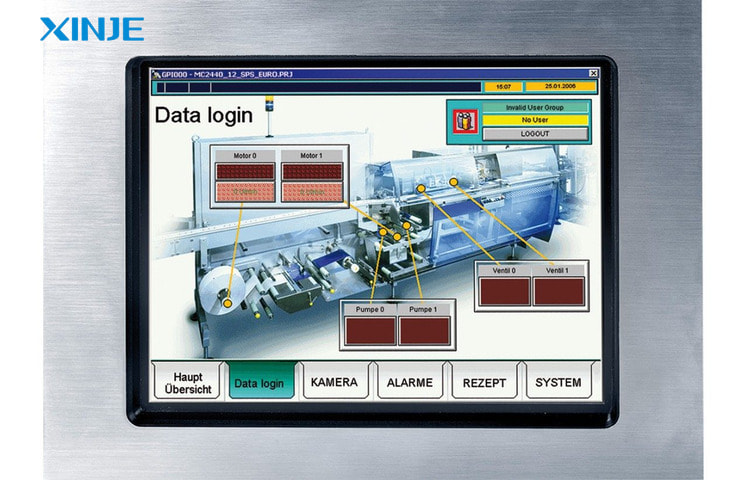

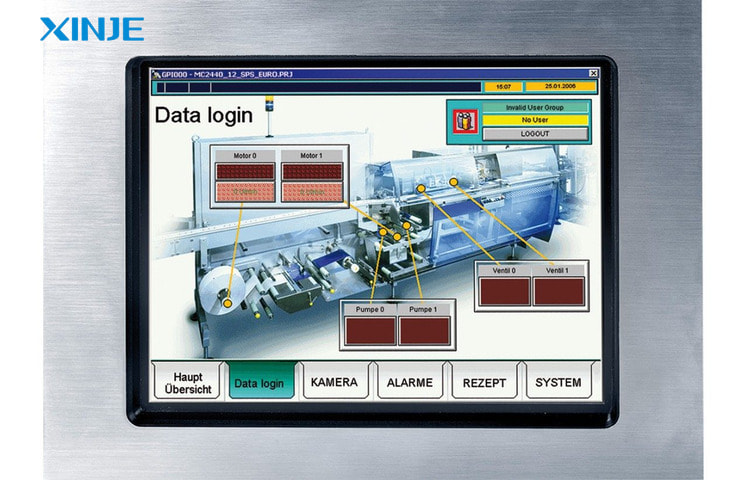

- Design display interface: Link Modbus tags to display objects such as gauges, charts, buttons, etc. so that users can monitor and control directly on the HMI screen.

- Test and run: Check the transmission and reception signals between HMI and Slave device, ensure the data is displayed correctly, no connection errors.

Thanks to this process, Modbus helps HMI collect, display and control devices quickly, cost-effectively, suitable for all automation systems from small to large scale.

Why is Modbus often integrated in HMI?

In order for HMI to communicate effectively with devices such as PLCs, inverters, sensors, it is mandatory to use a popular, easy-to-deploy communication protocol – and Modbus is the most popular choice.

- Popularity and high standardization: Modbus is one of the oldest industrial communication protocols, supported by thousands of equipment manufacturers around the world.

- Easy to configure, quick to deploy: Compared to other complex protocols, Modbus has a simple data frame structure, clear configuration process. Users only need to determine the correct device address, communication parameters (baud rate, parity …) and register mapping to be able to transmit and receive data immediately.

- Diverse connection standards: Modbus supports both serial transmission (Modbus RTU – RS-232/RS-485) and transmission via Ethernet (Modbus TCP). This helps to flexibly design the system, from small scale (point-to-point serial) to large scale (LAN).

- Optimizing investment costs: Thanks to Modbus, businesses do not need to invest in additional expensive gateway modules to connect devices from other manufacturers. All data is transmitted via a common protocol, HMI only plays the role of collecting, displaying and controlling.

- Easy expansion: When needing to add new devices, users only need to install additional Slave addresses and register mapping, without having to change the entire system. This helps businesses save time and costs to expand the line.

With the above advantages, Modbus is almost the default choice when building HMI systems in automation – from production lines, water treatment stations, power plants to industrial IoT solutions.

What are the common errors when using Modbus in HMI?

During the process of setting up and operating Modbus with HMI, users often encounter some of the following common errors:

Slave device not recognized

- This error often occurs when the physical connection (cable, COM port) is incorrect, or the Slave device is not fully powered.

- How to handle: Check the cable, communication port, make sure the Slave is operating and in the correct communication mode.

Incorrect address or communication parameters:

- Modbus requires the Slave address, baud rate, parity bit to match between the Master (HMI) and Slave. Small deviations can also cause communication failure.

- How to handle: Verify the Slave address again, check parameters such as baud rate, stop bit, parity according to the device’s instructions.

Transmission signal interference error:

- When using Modbus RTU via RS-485, long signal wires running parallel to the power cord can cause interference.

- How to handle: Use anti-interference cable, add signal repeater if the distance is long, or install standard transmission line termination resistors.

Quick fix

- Use Modbus test software to check each device separately.

- Read the error log of HMI or PLC to isolate the problem.

- Update device firmware if necessary.

What to note when deploying Modbus in HMI?

To ensure the HMI system communicates via Modbus stably, durably and safely, you need to pay attention to the following important points:

- Transmission security: With Modbus TCP, make sure the Ethernet network is protected by a firewall, password and clear authorization. Limiting access rights will help avoid the risk of data interference from outside.

- Choose the right cable and connection standard: If using Modbus RTU, prioritize quality RS-485 cables with anti-interference layer. The line should be separated from the power cord to limit signal interference, keeping the connection stable.

- Backup and check regularly: Regularly back up the HMI configuration file and Modbus parameters to avoid data loss. At the same time, periodically check the cables, connections and communication parameters to detect errors in time.

Conclusion

Using Modbus in HMI brings many benefits to the automation system, from the ability to connect diverse devices, easy configuration to cost savings and stable operation. Just master the operating principles, basic setup process and note factors such as security, connection standards, periodic maintenance, businesses can fully exploit the power of Modbus to monitor and control the production line more effectively.

If you are looking for an optimal Modbus-supported HMI solution, do not hesitate to contact XINJE’s technical team for advice and implementation of the most suitable system for your factory!