HMI Programming Software is an indispensable tool for designing and operating human-machine interfaces in modern automation lines. This article will help you understand what HMI programming software is, its outstanding features, how to choose the right one as well as the basic programming process to optimize the operating system.

What is HMI Programming Software?

HMI Programming Software is a tool that helps engineers design and configure the human machine interface (Human Machine Interface) on HMI devices. Through this software, users can create screens displaying machine status, control buttons, charts, warnings… to monitor and control the automatic system.

HMI programming software acts as a bridge between the operator and the control system (usually PLC). It allows programming of communication elements such as:

- Displaying real data from PLC (temperature, speed, pressure, etc.)

- Sending control commands from HMI to the machine system

- Configuring alarms (Alarm), events (Event)

- Setting up a friendly, easy-to-use interface for operators

Depending on the HMI manufacturer (such as Siemens, Delta, Mitsubishi, etc.), each software will have its own interface and functions, but all aim to optimize the interaction between humans and machines in the automation line.

What are the important features in HMI programming software?

A quality HMI programming software often integrates many features to support engineers in easily designing, programming and managing the interface. Some outstanding features include:

- Drag & Drop interface design: Helps users quickly create buttons, indicator lights, charts without having to write too much code.

- Multi-language, multi-screen support: Allows interface deployment for multiple operating locations and meets the language requirements of multinational factories.

- Diverse library of icons and objects: Provides ready-made industrial, device, and warning icons for quick design.

- Flexible connection with PLC: Compatible with many types of PLCs from different manufacturers, making the system easy to expand.

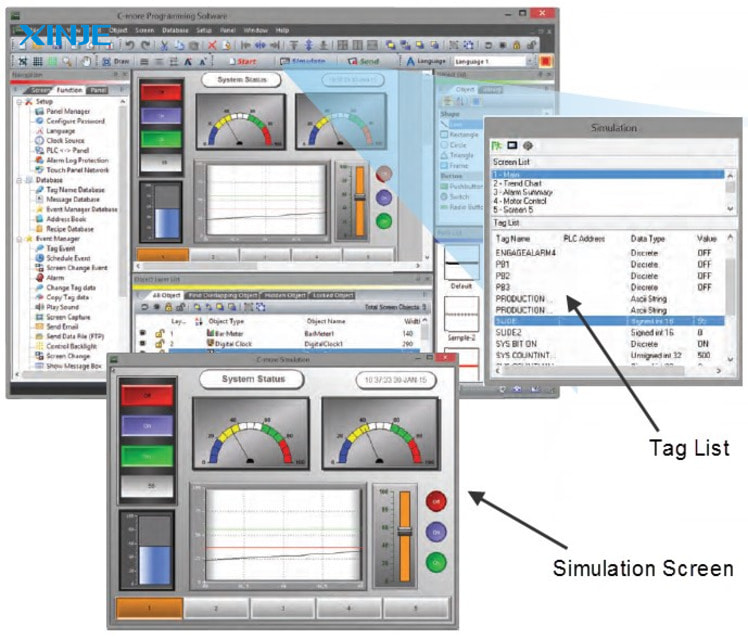

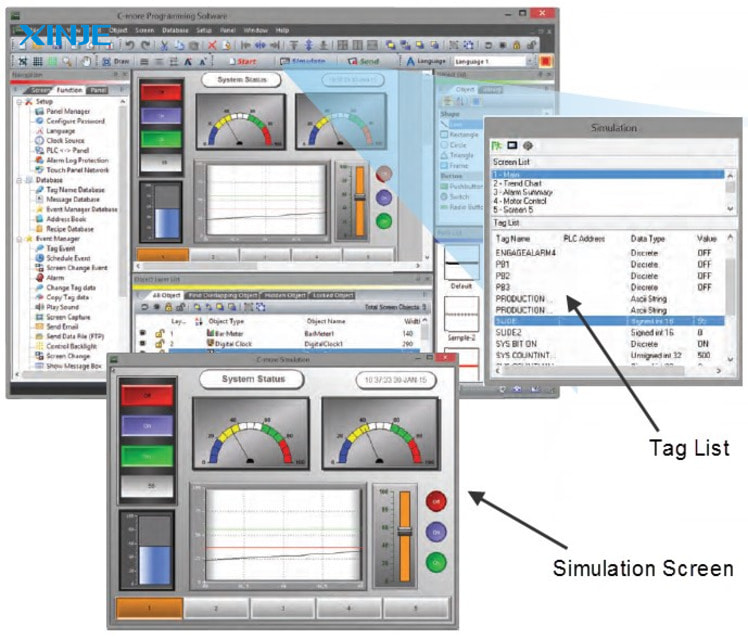

- Simulation mode: Allows testing the program before downloading to real devices, limiting technical errors.

- Security features: Set user authorization, access password, ensure data security and operation.

- Friendly interface: Easy-to-use design, supports engineers to operate quickly, reduces training time.

How many steps are there to program a basic HMI?

To program a complete HMI interface, engineers often perform the following 7 steps in sequence:

Step 1: Prepare software and equipment

- Install the correct HMI Programming Software corresponding to the HMI brand being used (eg WinCC, DOPSoft, GT Works …).

- Connect the HMI to the computer via USB cable or COM/Ethernet port.

- Install the driver if necessary for the computer to recognize the device.

Step 2: Create and configure a new project

- Initialize a new project in the software.

- Select the type of HMI screen being used (model, size).

- Set up basic parameters: communication port, PLC address, baud rate.

Step 3: Design the human-machine interface

- Drag and drop objects such as buttons, indicator lights, gauges, charts …

- Arrange the layout clearly and easily.

- Set up colors, icons, languages if necessary.

Step 4: Set up data link with PLC

- Assign addresses to objects (e.g. PLC input/output address).

- Set bits, words, data blocks to match the PLC program.

- Make sure the HMI and PLC signals match.

Step 5: Test, simulate the program

- Run Simulation mode to check operation.

- Observe button response, indicator lights, display data.

- Fix errors (if any) before downloading to the real device.

Step 6: Upload program to HMI

- Connect the device, download the program to HMI.

- Run a test run on the real system.

- Make sure the HMI operates stably, displaying correct information.

Step 7: Backup and maintenance

- Store programming files for easy editing later.

- Update software/firmware version if necessary.

What are the notes when using HMI Programming Software?

For the HMI programming process to go smoothly and limit risks, engineers need to note some important points:

- Check compatibility: Before installing, make sure the programming software is compatible with the HMI model and computer operating system in use.

- Use the latest version: Always update the new software version to patch errors and add new features, avoiding unexpected errors during the programming process.

- Backup regularly: During the design process, save and back up programming files periodically to prevent data loss when the software crashes.

- Check before downloading: Always run simulations to ensure operations and signals work properly before downloading directly to the real device.

- Skill training: For new employees, there should be a training plan to familiarize them with the software and comply with standard programming procedures.

- Update device firmware: In addition to software, make sure the HMI firmware is always at a stable version, compatible with the PLC and control system.

What are the notes when choosing HMI programming software for businesses?

To choose the right HMI Programming Software, businesses should consider the following factors:

- Suitable for the HMI line in use: Each company often develops its own software for its equipment, for example Siemens uses WinCC, Delta uses DOPSoft…

- PLC compatibility: Ensure the software supports good communication with the PLC type in the production line.

- Easy to learn, easy to use: For factories that regularly undergo maintenance, choosing software with a friendly interface will save time training employees.

- Good technical support: Choose software with a large user community, complete documentation and quick support services.

- Reasonable cost: Depending on the size of the business, you should consider software with a license and maintenance cost that fits your budget.

Conclusion

HMI Programming Software is an indispensable tool in the process of designing and operating modern automation control systems. Choosing the right software, using it proficiently and following the basic programming steps will help businesses optimize the production line, ensuring the system operates stably, safely and is easy to maintain.

Investing time in learning how to use HMI programming software effectively will bring long-term benefits to engineers and businesses, helping to save costs, limit risks and improve productivity.