The Industrial Internet of Things (IIoT) refers to the use of connected devices, smart sensors, and advanced analytics to enhance industrial processes. IIoT is an extension of the broader Internet of Things (IoT), specifically designed for industrial automation environments such as manufacturing plants, logistics centers, and energy systems. By bridging the gap between the physical and digital worlds, IIoT enables data-driven decision making, predictive maintenance, and real-time monitoring.

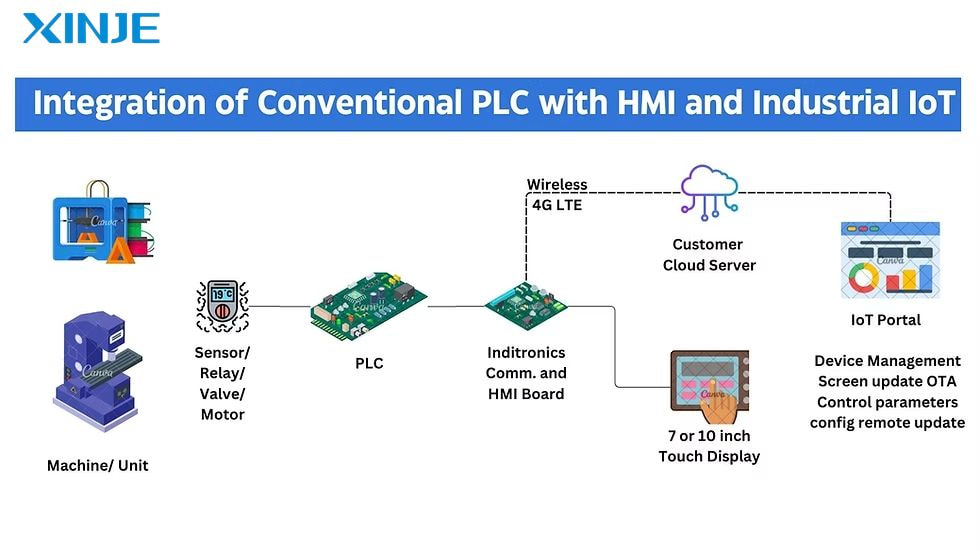

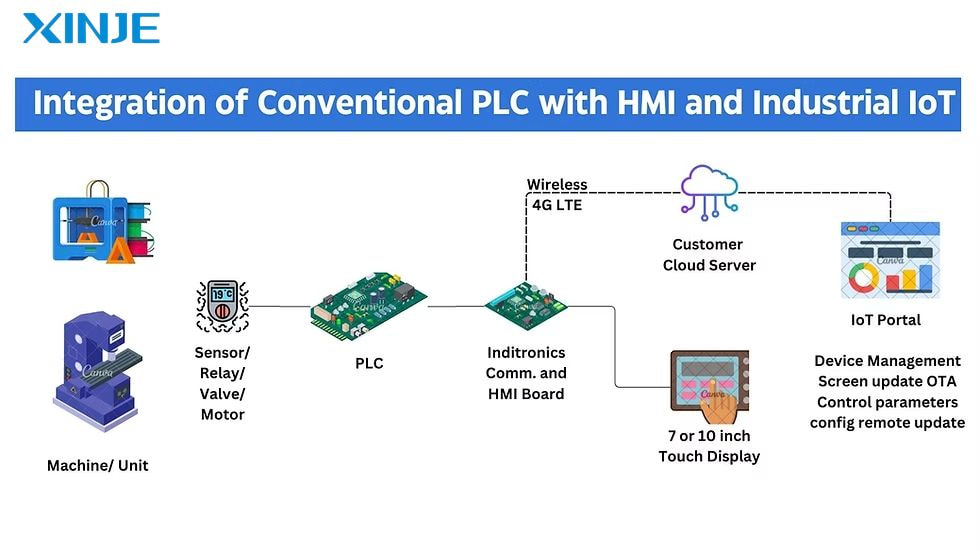

A key element in the IIoT ecosystem is the Human Machine Interface (HMI). HMIs have evolved to support IIoT-enabled features, becoming the gateway between operators and smart devices. As industries rapidly embrace digital transformation, the integration of IIoT and HMIs is no longer optional but essential for optimal efficiency, safety, and operational performance.

What are the salient features of IIoT?

IIoT brings powerful capabilities to the manufacturing automation industry, such as remote monitoring and control, predictive maintenance, data-driven decision making, etc. These features are the foundation of its value and define how it reshapes traditional operations

- Remote monitoring and control: Operators and managers can access real-time dashboards through web-based or cloud-based HMIs, eliminating the need for on-site presence.

- Predictive maintenance: IIoT systems can predict equipment failures before they occur, reducing downtime, maintenance costs, and improving business continuity.

- Data-driven decision making: With IIoT, large volumes of machine data are collected, analyzed, and visualized through advanced HMIs to provide operators with the insights they need to make informed, real-time decisions, improving overall efficiency and safety.

- Scalability and Flexibility: IIoT platforms are built with the goal of being scalable from a single production line to an entire factory, and IIoT systems are easily extensible and integrate with legacy systems, especially when combined with modern HMI panels.

- Edge and Cloud Integration: IIoT architectures utilize both edge and cloud computing. HMI systems integrated with edge capabilities can respond more quickly to local events while still leveraging cloud analytics.

How does IIoT impact HMI?

IIoT is not only changing the way data is collected, but it is also redefining the nature of HMI systems

- From Static Interfaces to Intelligent Visualizations: Modern HMI systems, powered by IIoT, now offer interactive dashboards, customizable KPIs, and 3D visualizations, creating a more intuitive user experience.

- Real-Time Data Feeds: IIoT enables continuous real-time data to be transmitted to the HMI. This enables up-to-the-second monitoring, alarms, and alerts, helping operators respond quickly to abnormalities or emergencies.

- Enhanced Security and Access Control: Modern HMIs now support features such as user authentication, data encryption, and role-based access control, ensuring that only authorized users can interact with critical systems.

- Improved maintenance and troubleshooting: IIoT-enabled HMIs can provide detailed diagnostics, machine history logs, and recommended solutions when failures occur.

What should be noted when combining IIoT and HMI?

Integrating IIoT with HMIs can be hugely beneficial, but also requires careful planning and implementation to ensure smooth operations

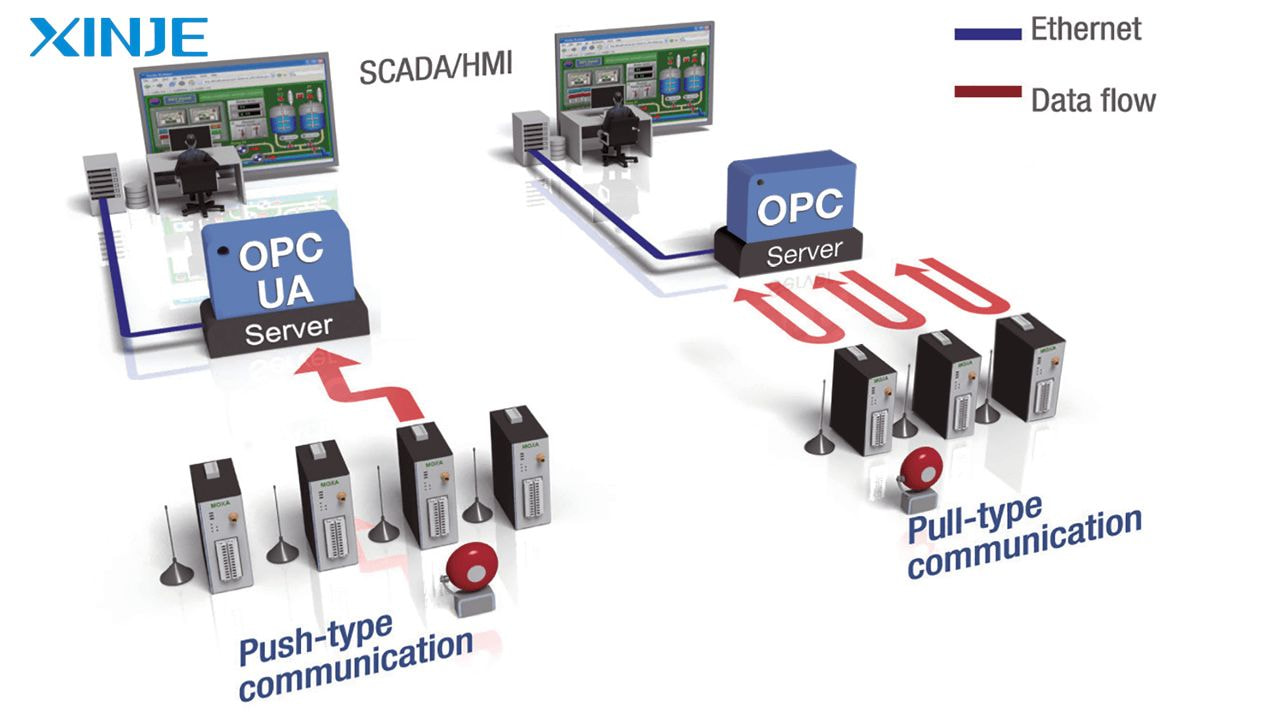

- Protocol compatibility: ensure that the HMI supports IIoT communication protocols such as OPC UA, MQTT, Ethernet/IP, or BACnet.

- Edge vs. Cloud deployment: Edge processing provides low latency and better local control, while cloud analytics supports centralized insights and scalability.

- Cybersecurity measures: Always implement robust security layers, including firewalls, VPNs, intrusion detection systems, and software patches to prevent unauthorized access to IIoT-connected HMIs.

- Data management strategy: IIoT systems generate massive amounts of data. Have a clear data management plan that addresses storage, analysis, visualization, and retention, all within the HMI framework.

- System Integration and Interoperability: Ensuring your IIoT-HMI integration is compatible with existing SCADA, MES, and ERP systems will create a unified, smart factory where information flows freely and securely.

How are IoT and IIoT different?

While IoT and IIoT share similar underlying technologies—like sensors, cloud computing, and wireless connectivity—they differ significantly in application, scale, and impact.

| Feature | IoT (Consumer) | IIoT (Industrial) |

| Data Volume | Moderate | Very high |

| Reliability | Moderate priority | Mission-critical |

| Latency Tolerance | Seconds | Milliseconds or less |

| Communication Protocols | Wi-Fi, Bluetooth | OPC UA, MQTT, Modbus TCP |

| Primary Use | Smart homes, wearables, and automation | Manufacturing, logistics, energy |

In short, IIoT focuses on reliability, determinism, and scalability required in industrial applications, while IoT targets consumer-level convenience and personalization.

Conclusion

The integration of IIoT and HMI represents a significant step forward in industrial automation. By combining real-time data, intelligent visualization, and cloud connectivity, IIoT-enabled HMI systems provide unparalleled visibility and control of operations. This integration not only boosts productivity and reduces downtime, but also prepares factories for the future of Industry 4.0.

As more industries invest in smart manufacturing, the collaboration between IIoT and HMI will become the new standard in intelligent control systems.